Droplet microfluidic technology based method for preparing chromatographic packing with uniform and controllable grain size

A technology of microfluidic technology and chromatographic packing, which is applied in the field of chromatographic packing with uniform and controllable particle size based on droplet microfluidic technology, which can solve the problems of poor monodispersity and achieve the effect of excellent monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

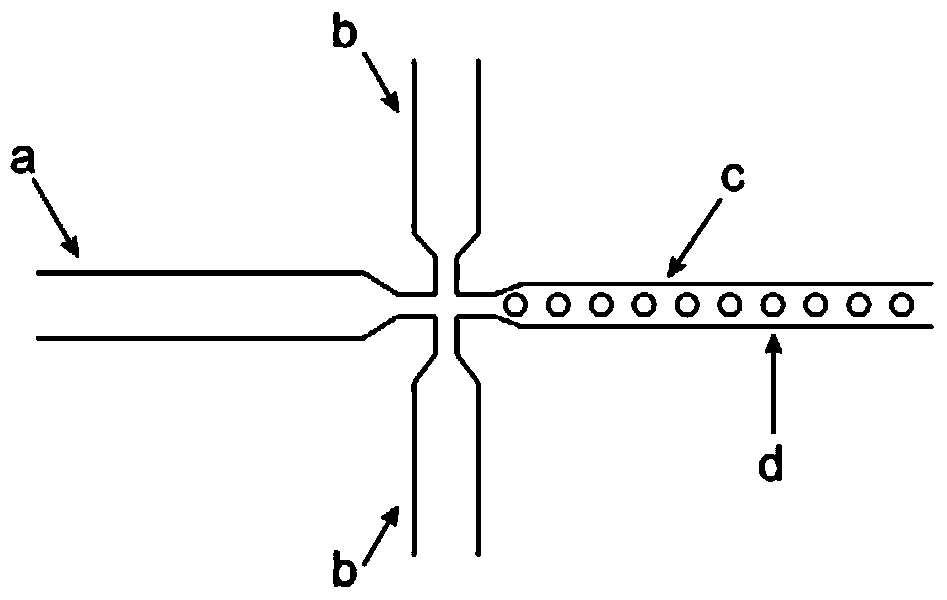

[0026] Add 1.8 mL of tetramethoxysilane (TMOS) and 2 mL of 3-glycidyloxypropyltrimethoxysilane (GPTMS) and 540 mg of polyethylene glycol (PEG) into 5 mL of 0.01 M acetic acid solution, in an ice-water bath (0°C) under magnetic stirring for 1 h, until completely hydrolyzed into a transparent and uniform solution. Then take 2 mL of the hydrolyzed solution in a 5 mL centrifuge tube, add 80 mg of L-lysine hydrochloride, sonicate until it is completely dissolved, and use it as the dispersed phase. 0.5 g of EM90 was dissolved in 9.5 g of mineral oil as the continuous phase. The dispersed phase and the continuous phase were introduced into the microfluidic chip by using a precision syringe pump (such as figure 1 ), where the chip depth is 50 μm, the width of horizontal channel a and vertical channel b is 200 μm, the width of horizontal channel and vertical channel at the intersection is 50 μm, and the width of droplet channel c is 120 μm. At the interface, the dispersed phase was "...

Embodiment 2

[0031] Add 1.8 mL of tetramethoxysilane (TMOS) and 2 mL of 3-glycidyloxypropyltrimethoxysilane (GPTMS) and 540 mg of polyethylene glycol (PEG) into 5 mL of 0.01 M acetic acid solution, in an ice-water bath (0°C) under magnetic stirring for 1 h, until completely hydrolyzed into a transparent and uniform solution. Then take 2 mL of the hydrolyzed solution in a 5 mL centrifuge tube, add 80 mg of L-lysine hydrochloride, sonicate until it is completely dissolved, and use it as the dispersed phase. 0.5 g of EM90 was dissolved in 9.5 g of mineral oil as the continuous phase. The dispersed phase and the continuous phase were introduced into the microfluidic chip by using a precision syringe pump (such as figure 1 ), where the chip depth is 50 μm, the width of horizontal channel a and vertical channel b is 200 μm, the width of horizontal channel and vertical channel at the intersection is 50 μm, and the width of droplet channel c is 120 μm. At the interface, the dispersed phase was "...

Embodiment 3

[0033] Add 1.8 mL of tetramethoxysilane (TMOS) and 2 mL of 3-glycidyloxypropyltrimethoxysilane (GPTMS) and 540 mg of polyethylene glycol (PEG) into 5 mL of 0.01 M acetic acid solution, in an ice-water bath (0°C) under magnetic stirring for 1 h, until completely hydrolyzed into a transparent and uniform solution. Then take 2 mL of the hydrolyzed solution in a 5 mL centrifuge tube, add 80 mg of L-lysine hydrochloride, sonicate until it is completely dissolved, and use it as the dispersed phase. 0.5 g of EM90 was dissolved in 9.5 g of mineral oil as the continuous phase. The dispersed phase and the continuous phase were introduced into the microfluidic chip by using a precision syringe pump (such as figure 1 ), where the chip depth is 20 μm, the width of horizontal channel a and vertical channel b is 100 μm, the width of horizontal channel and vertical channel at the intersection is 20 μm, and the width of droplet channel c is 80 μm. At the interface, the dispersed phase was "c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com