In-tube concentric double helix static mixer

A technology of static mixer and internal spiral, which is applied in fluid mixers, mixers, chemical instruments and methods, etc., can solve problems such as poor mixing performance and unsatisfactory pressure drop, and achieve small flow resistance, improved mixing effect, The effect of a large hydraulic diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

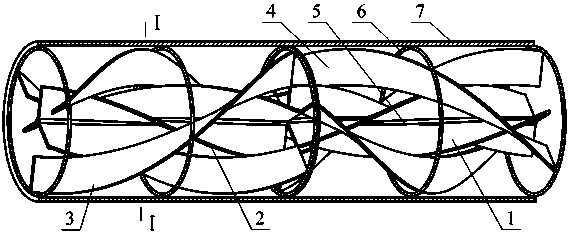

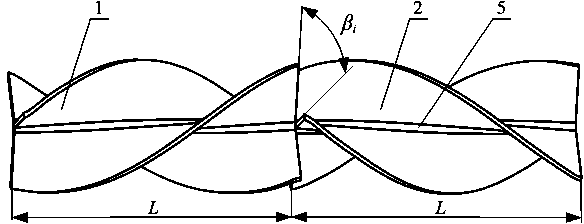

[0036] Such as Figure 1-6 Shown: the in-pipe concentric double-helix static mixer provided by the present invention includes a left-handed blade 1, an inner right-handed blade 2, an outer left-handed blade 3, an outer right-handed blade 4, a positioning round rod 5, a positioning ring 6 and a pipe body 7.

[0037] The inner and outer spiral blades 1, 2, 3, and 4 are all made of stainless steel plates, and the two ends are directly twisted with a clamp or stamped with a special mold. The aspect ratio (the ratio of the axial length of the spiral plate to the inner diameter of the pipe) is 1.0 ~3.0, the twist angle is between 90°~270°, and the thickness of the spiral blade is about 2~3mm. Both the positioning rod and the positioning ring are made of round steel with a diameter of 3~4mm, and the positioning ring should ensure that its outer diameter fits closely with the inner wall of the pipe.

[0038] During the manufacturing process, the inner and outer helical elements must...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com