Integrated Magnatoresistive Sensing device

A technology of magnetoresistive sensors and magnetoresistive sensing elements, applied to instruments, measuring magnetic variables, measuring devices, etc., can solve problems such as difficult testing and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

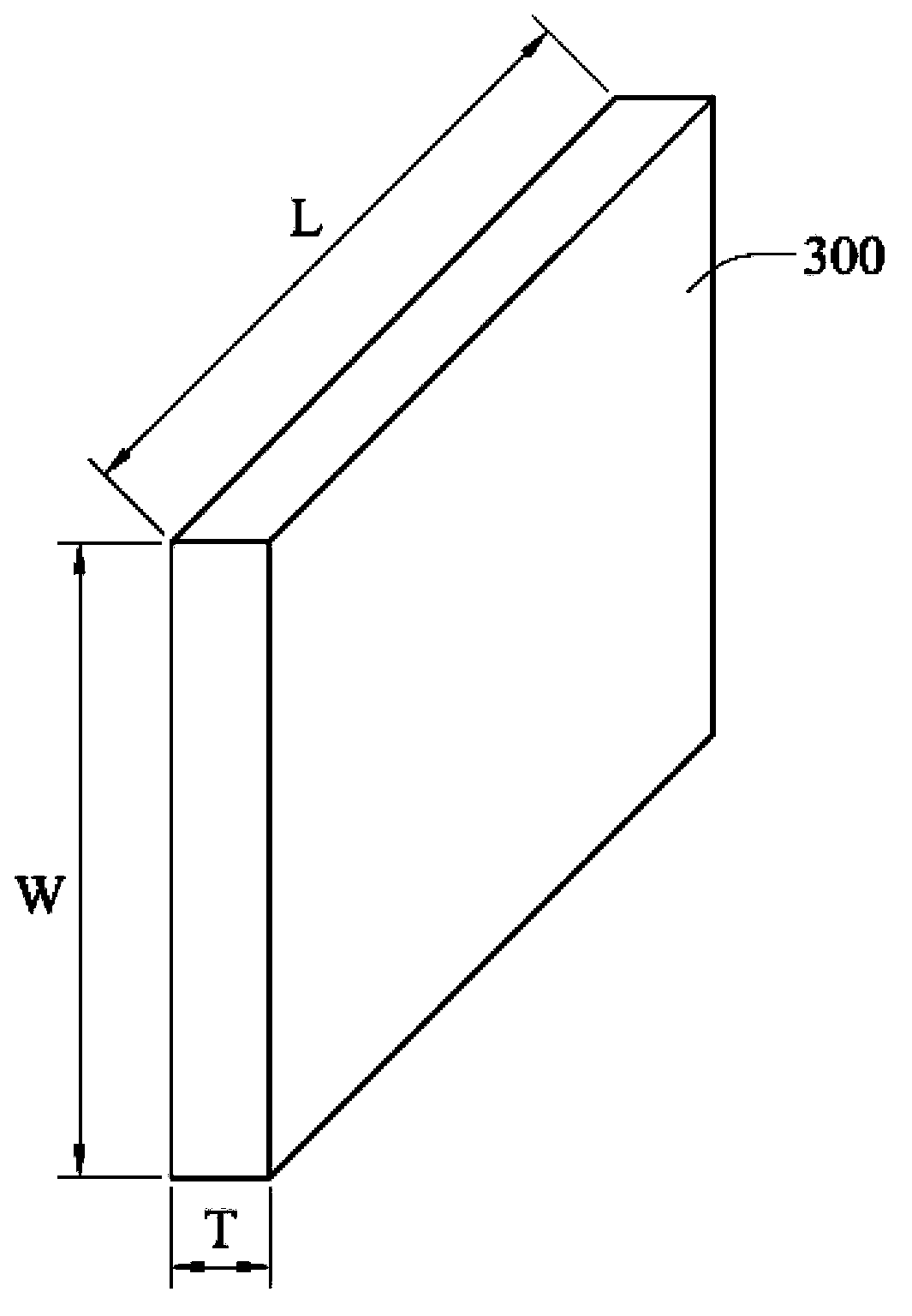

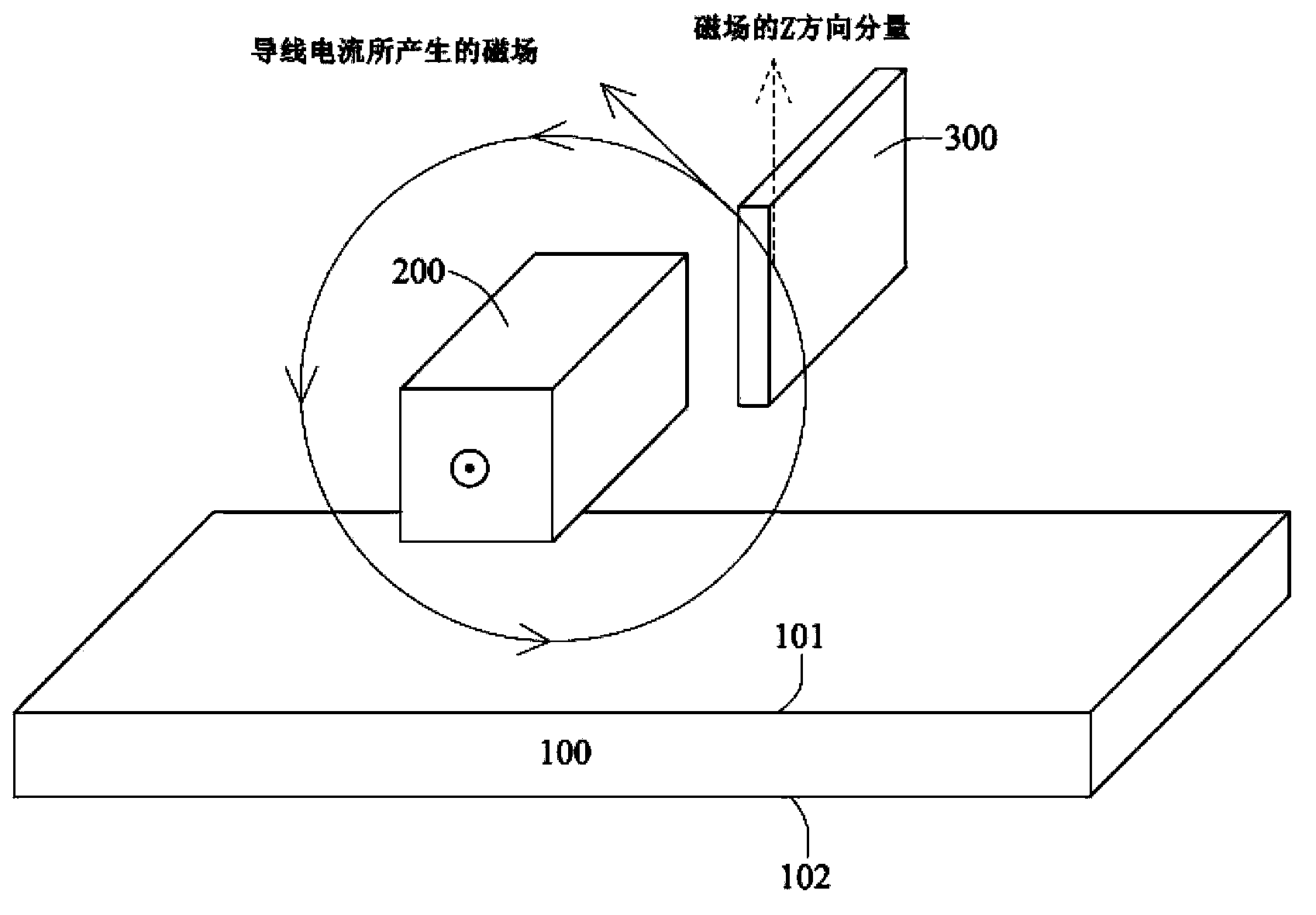

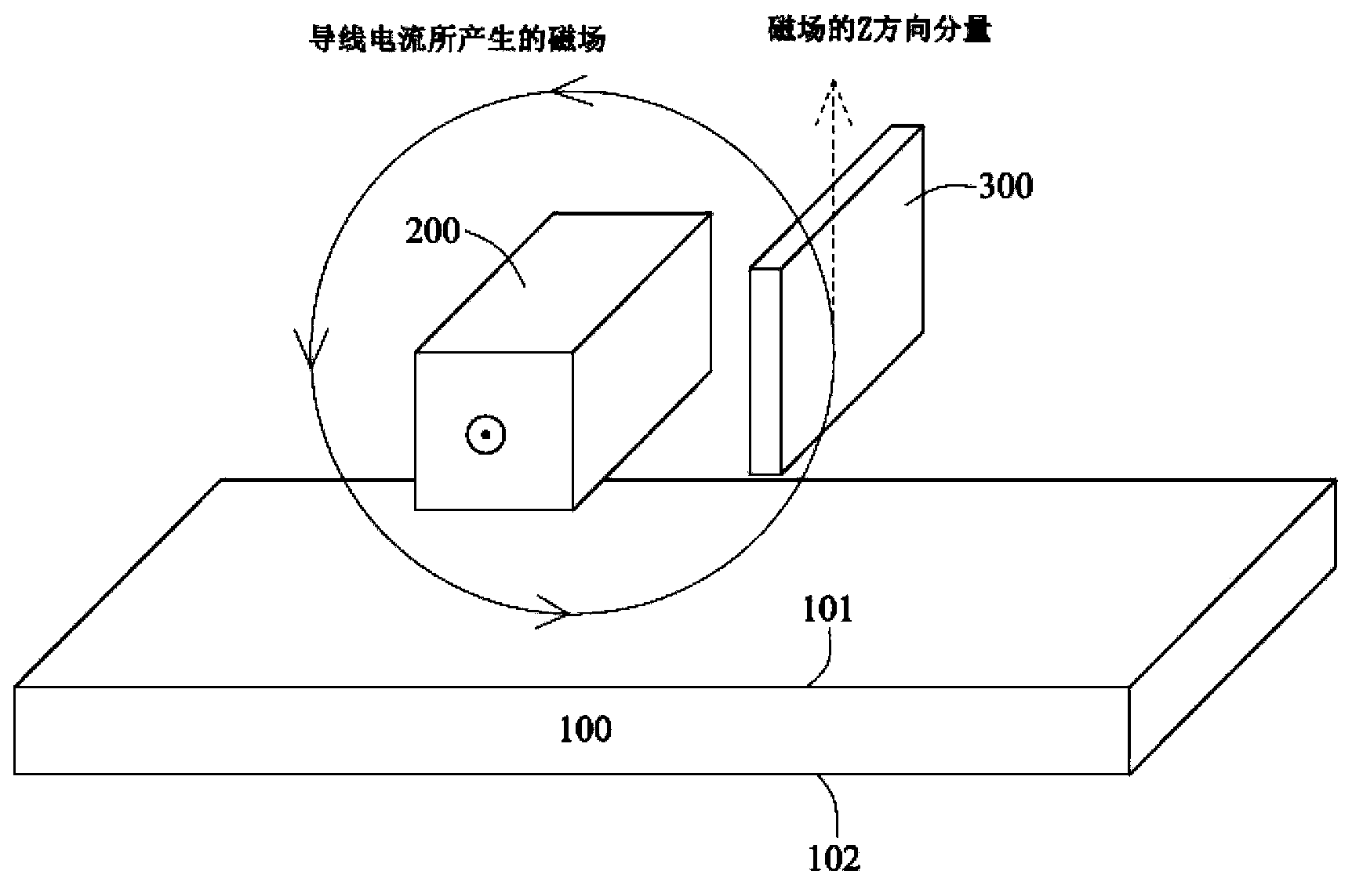

[0036] What the present invention is discussing here is an integrated magnetoresistive sensor, especially for the magnetoresistive sensor element and its built-in self-test unit for sensing the magnetic field in the Z-axis direction, and can include other structures commonly used in sensors such as: Setting / resetting circuit; magnetoresistive sensing element for sensing the magnetic field in the X / Y axis direction; various circuits for amplifying signals, filtering signals, and converting signals; shielding unwanted electromagnetic interference shielding structure....etc. In order to describe the present invention thoroughly and clearly without blurring the focus of the present invention, these commonly used structures are not introduced, but the integrated magnetoresistive sensor of the present invention may optionally include these commonly used structures.

[0037] The preferred embodiments of the present invention will be described in detail below. For example, all compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com