Real-time detection method for high-speed rail injury based on vibration and audio composite signals

A high-speed railway and composite signal technology, applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of high traffic density, affecting the efficiency of train operation, and high speed, so as to improve accuracy, improve work efficiency, and ensure safety running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

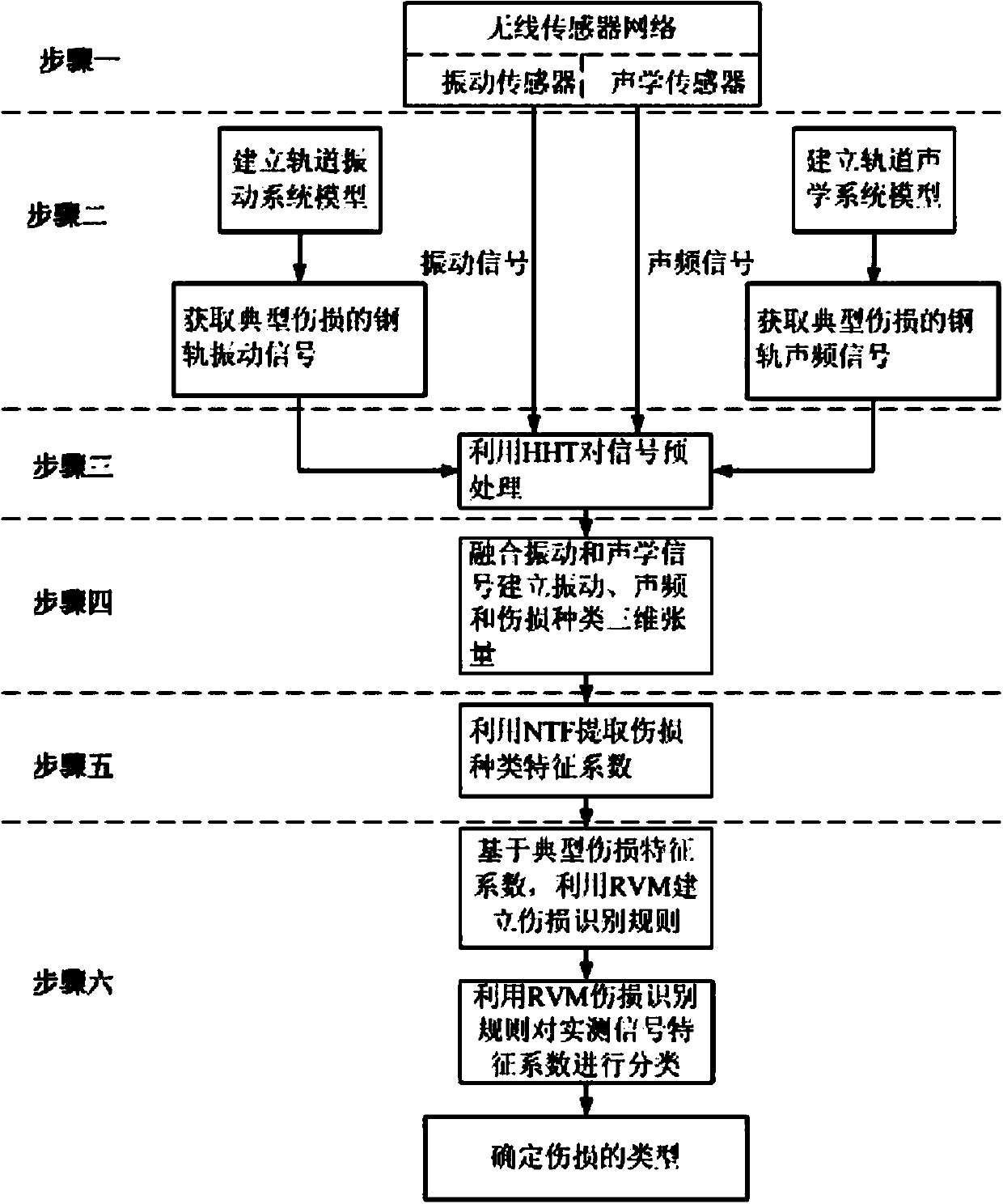

[0026] Specific implementation mode 1: This implementation mode provides a real-time detection method for high-speed railway rail damage based on vibration and audio frequency composite signals, such as figure 1 As shown, it is divided into six steps, the specific steps are as follows:

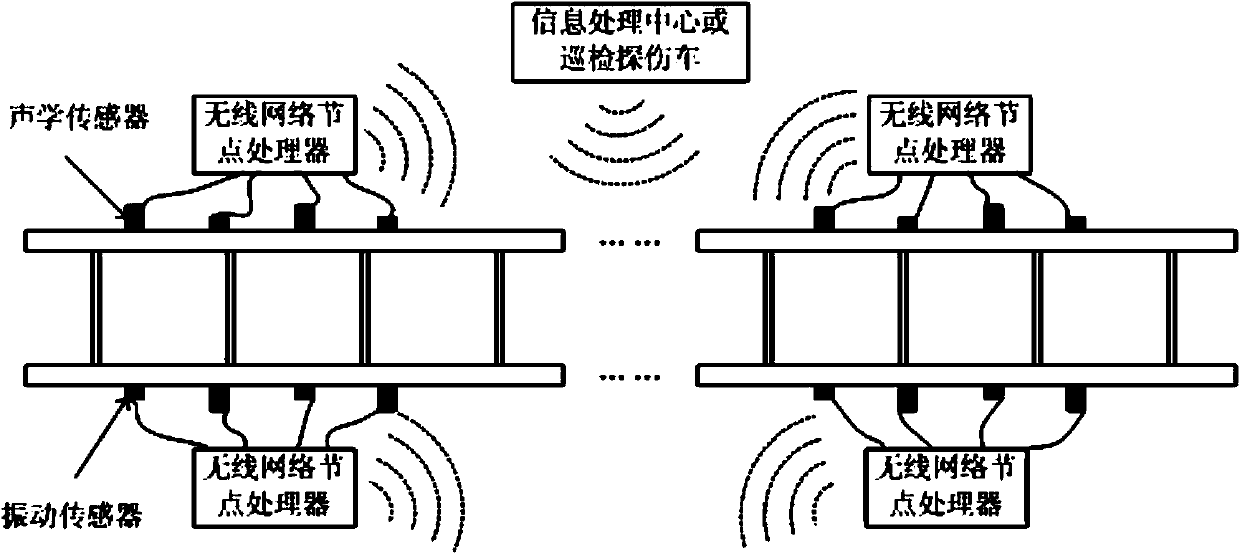

[0027] Step 1: Install vibration sensors and acoustic sensors on the rails of high-speed railway tracks, combine with wireless network node processors to form a distributed wireless sensor network along the high-speed railway, and collect rail vibration signals and audio signals in real time.

[0028] A distributed wireless sensor network for flaw detection in high-speed railways contains two types of sensors: vibration sensors and acoustic sensors. The vibration sensor is mainly used to collect the vertical vibration signal of the track to obtain various vibration signals generated by the track itself and the wheel-rail interaction when the train passes by, and also includes the vibration cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com