High Performance Low Prestressed Concrete Solid Square Pile

A low-prestressed, concrete technology, used in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems affecting the durability of precast piles, lack of protective measures for connections, and reduced pile bearing capacity, and increase corrosion margins. , The effect of large impact resistance area and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below:

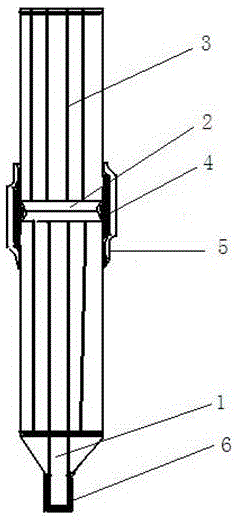

[0020] As shown in the figure, a high-performance low-prestressed concrete solid square pile includes a pile body and a pile head 1. The pile body is composed of one or more section unit piles, and the unit piles are composed of concrete and parallel steel bars 3 in the concrete. , the two ends of the steel bar 3 are respectively connected with the connecting plate 2, the adjacent two connecting plates 2 are welded to form a pile body, the pile head 1 is conical, and the connecting plate can be annular, hollow square, etc. The prior art is the same, this will not be repeated, the present invention is characterized in that the anti-corrosion resin layer 4 is wound or smeared on the periphery of the two connecting discs, and the anti-corrosion resin layer 4 is provided with a carbon fiber layer 5 that can improve the anti-corrosion ability and tensile strength. The exposed steel bar is provided with an epoxy resin protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com