A preparation method of zinc titanate quantum dots loaded titanium dioxide nanobelts

A technology of titanium dioxide and quantum dots, applied in the field of material chemistry, can solve the problems of unreported photocatalytic performance and achieve the effects of stable shape control, cheap raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Synthesis of ZnTiO3 quantum dots modified TiO2 nanobelts:

[0021] First, add 0.8mol sodium hydroxide and 6mmol nano-titanium dioxide into 80mL deionized water, stir evenly, then transfer the mixed solution into a hydrothermal reaction kettle with polytetrafluoroethylene, tighten the seal, and put it in 180 o C constant temperature oven left to react for 10 hours; then the reaction product was repeatedly washed with deionized water until the pH value was 8; then washed 4 times with 0.2mol / L hydrochloric acid; the cleaned product was ultrasonically dispersed in the zinc nitrate aqueous solution, and Stirring was continued for 12 hours; the product was centrifuged to obtain a precipitate, which was dried in an oven at 60°C; finally, the dried powder was calcined in a muffle furnace at 600°C for 5 hours to obtain ZnTiO 3 Quantum dot modified TiO 2 nanobelt.

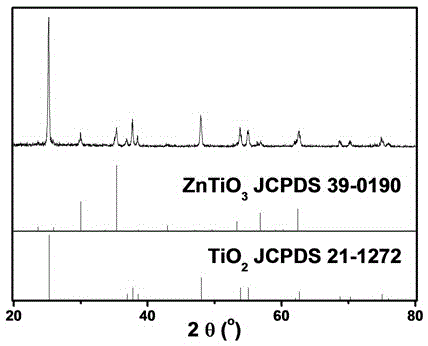

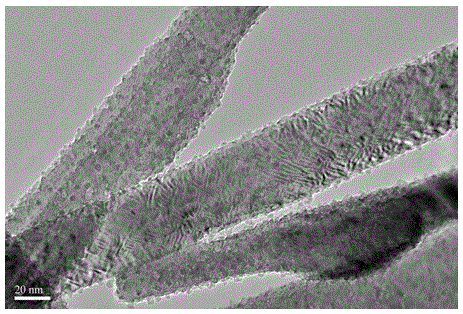

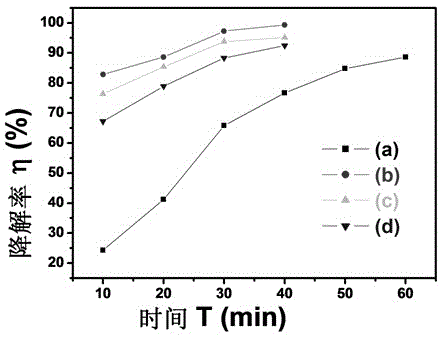

[0022] figure 1 It shows that the generated product contains ZnTiO 3 and TiO 2 two phases; figure 2 It shows...

Embodiment 2

[0024] Repeat Example 1, but replace nano titanium dioxide and zinc nitrate with n-butyl titanate and zinc chloride respectively to obtain ZnTiO 3 Quantum dot modified TiO 2 nanobelt. Figure 4 (c) shows that the degradation rate of methyl orange using the sample as an ultraviolet photocatalyst for 40 minutes is 93.4%.

Embodiment 3

[0026] Repeat Example 1, but replace nanometer titanium dioxide and zinc nitrate with titanium isopropoxide and zinc acetate respectively, obtain ZnTiO 3 Quantum dot modified TiO 2 nanobelt. Figure 4 (d) shows that the degradation rate of methyl orange using the sample as an ultraviolet photocatalyst for 40 minutes is 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com