Preparation method of zinc sulfide nuclear hollow microspheres

A technology of hollow microspheres and zinc sulfide, applied in the field of material chemistry, can solve the problems of less operation steps and long time, and achieve the effect of mild synthesis conditions, simple and easy method, and fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

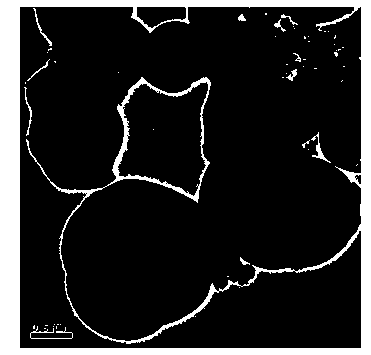

Image

Examples

Embodiment 1

[0018] Firstly, 5 mmol of aniline monomer was dissolved in 50 mL of carbon tetrachloride for later use, and then 5 mmol of zinc nitrate, 0.1 mol of sodium hydroxide and 5 mmol of sodium thiosulfate were dissolved in 50 mL of deionized water to obtain solution B, and then 50mL 0.1molL -1 The aqueous solution of sodium persulfate is added to solution B to obtain solution C, and finally solution C is added to the carbon tetrachloride solution of aniline to obtain a two-phase mixed solution with a clear interface (the water phase is on the upper oil phase and the oil phase is on the bottom); The phase mixture was left to stand at room temperature for 20 hours, and a pale yellow precipitate appeared on the two-phase interface; the precipitate was washed alternately with ethanol, tetrahydrofuran and deionized water, and was filtered by centrifuge precipitation or suction filtration equipment after each washing. The filtered product was redispersed in deionized water or ethanol, filt...

Embodiment 2

[0020] Repeat Example 1, but replace zinc nitrate and sodium thiosulfate with zinc chloride and thiourea respectively, to obtain ZnS cored hollow microspheres with a yield of 84.3%.

Embodiment 3

[0022] Repeat Example 1, but replace zinc nitrate and sodium thiosulfate with zinc acetate and thioacetamide respectively, to obtain ZnS cored hollow microspheres with a yield of 91.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com