Cage type electric mini-tiller and application thereof

A micro-tiller, electric technology, applied in the field of agricultural machinery, can solve the problems of high cost, difficulty in starting, high failure rate, and achieve the effects of light weight, low ground breaking power and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

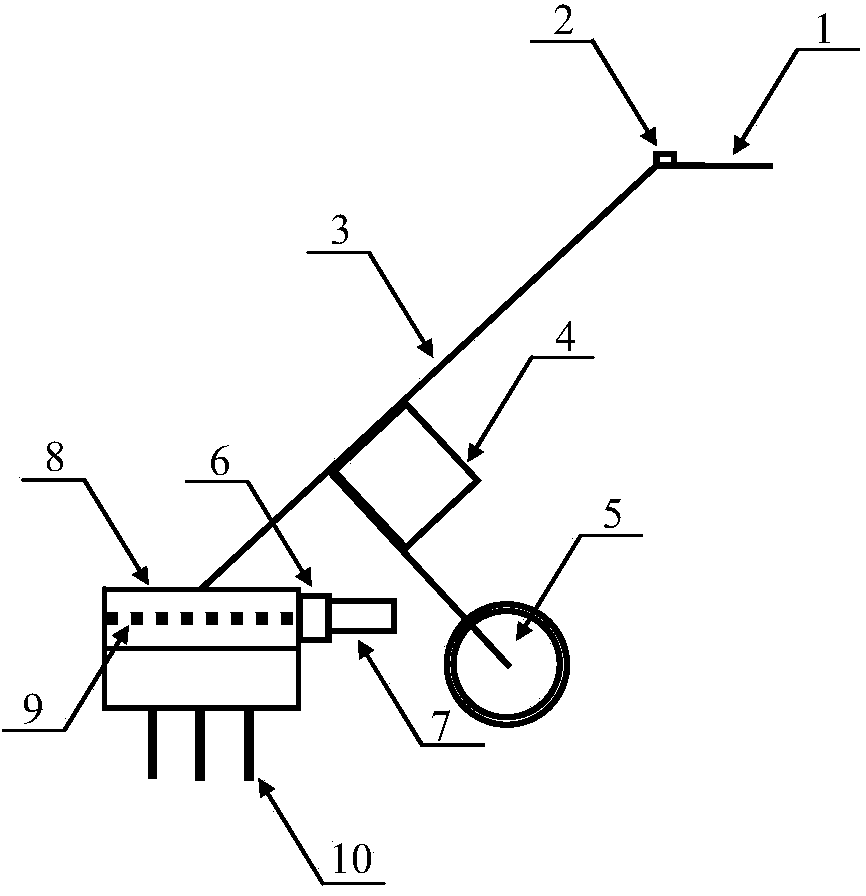

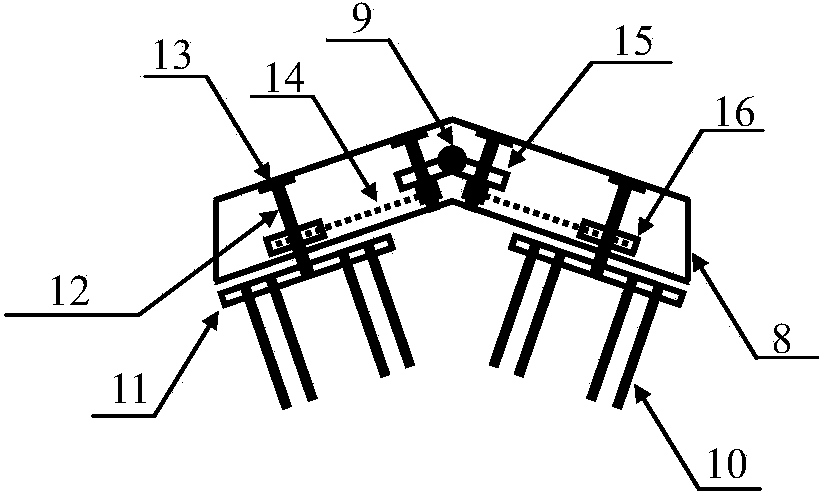

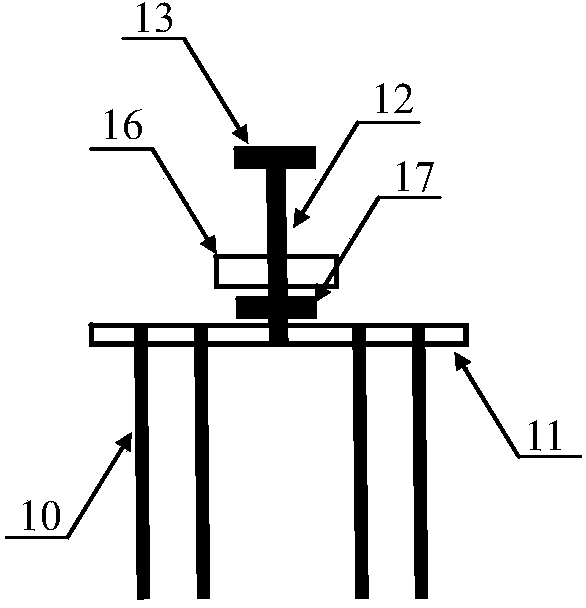

[0024] Such as figure 1 As shown, a cage-type electric tiller includes a frame 3, a machine head, a power mechanism, a transmission mechanism and an actuator; a control switch 2 is installed on the inside of the handle 1; one end of the frame 3 is fixedly connected with the handle 1, and the frame The other end of 3 is fixedly connected with shell 8, and the middle part of frame 3 is equipped with travel wheel 5, and power control box 4 is fixed on the junction of frame 3 and travel wheel 5 and plays tripod reinforcement effect, when non-cultivation operation walks, With the traveling wheel 5 as the fulcrum, the handle 1 is pressed down to raise the machine head to a certain height so that it can walk freely. Such as figure 2 As shown, the handpiece includes a shell 8, which is an inverted "V"-shaped shell with a cavity formed inside. Such as Figure 6 As shown, the power mechanism includes a motor 7, a reducer 6 and a lead screw 9, the motor 7 is fixed on the outer rear c...

Embodiment 2

[0027] The principle is the same as in Embodiment 1, and the storage battery inside the power supply control box 4 is a lithium-ion battery or a lead-acid storage battery, or is refitted into a wired power supply mode. Drive chain 14 can be changed into belt, and corresponding sprocket wheel also changes belt pulley into. The angle of the inverted "V"-shaped shell 8 can be adjusted according to the compactness and depth of the cultivation object. Generally, when the soil is loose or the cultivation depth is large, the angle of the "V" shape is smaller, and vice versa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com