Lithium battery anode and preparation method, lithium battery and preparation method and application

A lithium battery and positive electrode technology, applied in the lithium battery positive electrode and its preparation, lithium battery and its preparation field, can solve problems such as instability, battery safety hazards, inability to transfer lithium ions, etc., to achieve simple process, easy control of conditions, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

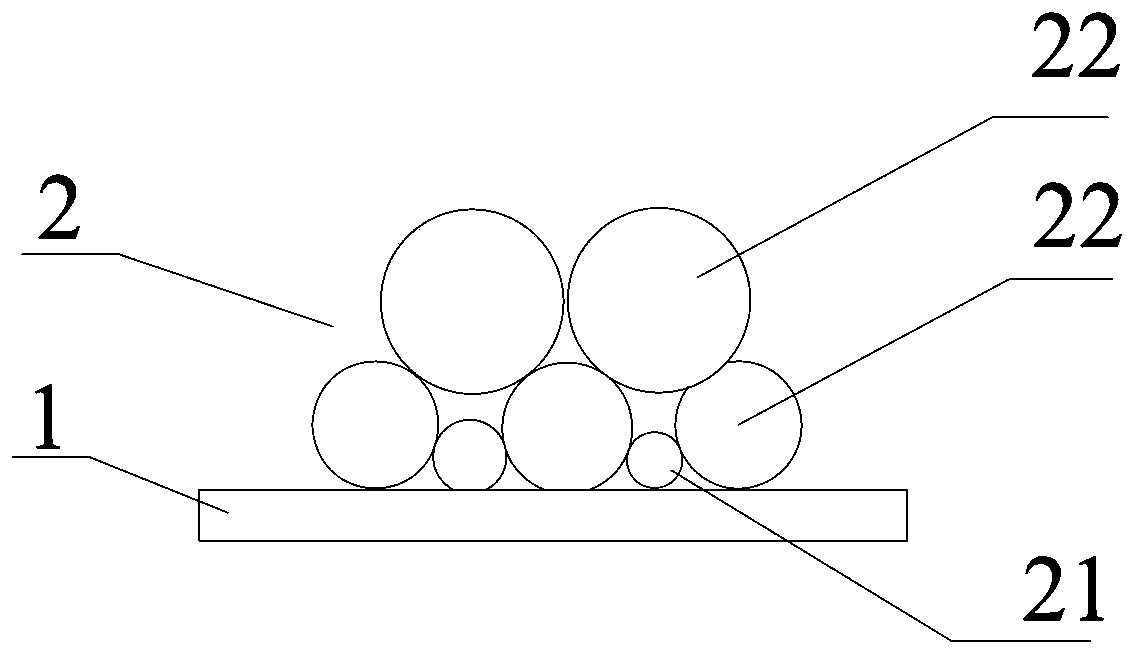

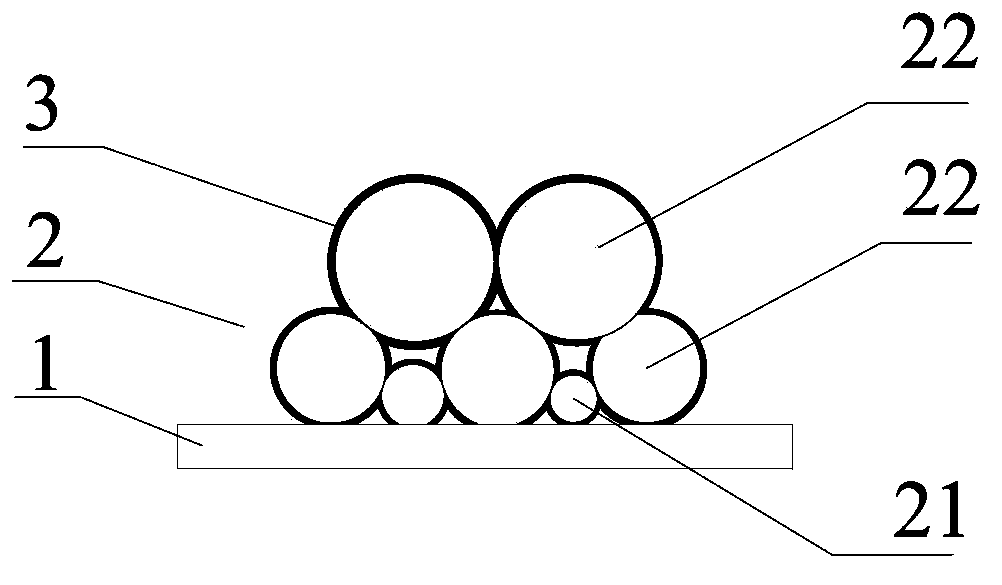

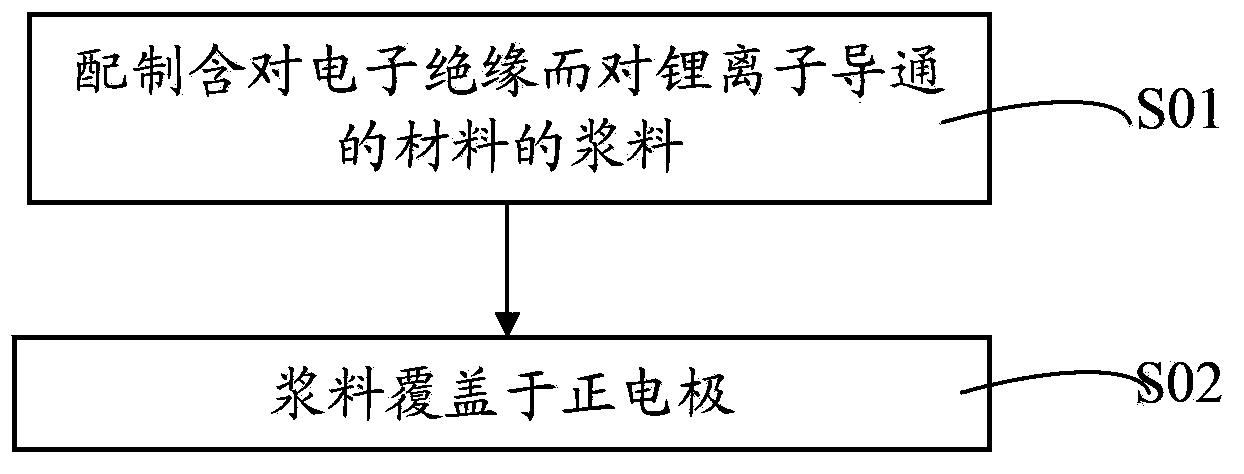

[0056] Correspondingly, the embodiment of the present invention also provides a method for preparing the positive electrode of the above-mentioned lithium battery. For the process flow of the method for preparing the positive electrode of the lithium battery, please refer to image 3 , see also figure 1 , 2 . The lithium battery positive electrode comprises the following steps:

[0057] Step S01. Prepare a slurry containing a material that is electrically insulated but conducts to lithium ions: mix the material that is electrically insulated but conducts to lithium ions with a solvent to prepare a slurry;

[0058] Step S02: Cover the positive electrode with the slurry: cover the positive electrode containing the positive electrode material layer 2 with the slurry prepared in step S01, and form the protective layer 3 after drying to obtain the positive electrode of the lithium battery.

[0059] Specifically, in the above step S01 , the materials that are electrically insulat...

Embodiment 1

[0081] A lithium battery positive electrode and a preparation method thereof, and a lithium ion battery:

[0082] The microstructure of the positive electrode of the lithium battery is as follows figure 2 As shown, the positive electrode of the lithium battery includes a current collector 1 , a positive electrode material layer 2 bonded to the surface of the current collector 1 , and a protective layer 3 bonded to the surface of the positive electrode material layer 2 and the pore walls of the positive electrode material layer 2 . Among them, the protective layer 3 contains lithium carbonate.

[0083] The positive electrode of the lithium battery is prepared as follows:

[0084] Preparation of the positive electrode: LiNi with a mass ratio of 80:10:10 0.5 mn 1.5 o 4 , conductive carbon, binder (polyvinylidene fluoride) and a certain amount of N-methylpyrrolidone solvent are uniformly mixed (the solid content of the final mixed solution is 45%) to obtain the positive elect...

Embodiment 2

[0092] A lithium battery positive electrode and a preparation method thereof, and a lithium ion battery:

[0093] The structure of the positive electrode of the lithium battery is the same as that of the positive electrode of the lithium battery in Example 1, except that the protective layer contains lithium carbonate, and the concentration of the precursor solution of the protective layer is 10%.

[0094] The positive electrode of the lithium battery is prepared as follows:

[0095] Preparation of the positive electrode: refer to the preparation of the positive electrode in Example 1;

[0096] Prepare a slurry containing materials that are electrically insulated and conductive to lithium ions: lithium hydroxide is dissolved in water, and an aqueous solution with a concentration of 10% by mass is prepared;

[0097] Positive electrode modification: The prepared positive electrode was immersed in a 10% lithium hydroxide aqueous solution, and the positive electrode sheet taken o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com