High-voltage high-compaction composite positive electrode material of lithium ion battery and preparation method

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as expensive cobalt, low safety of LiCoO2, and easy damage to the crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

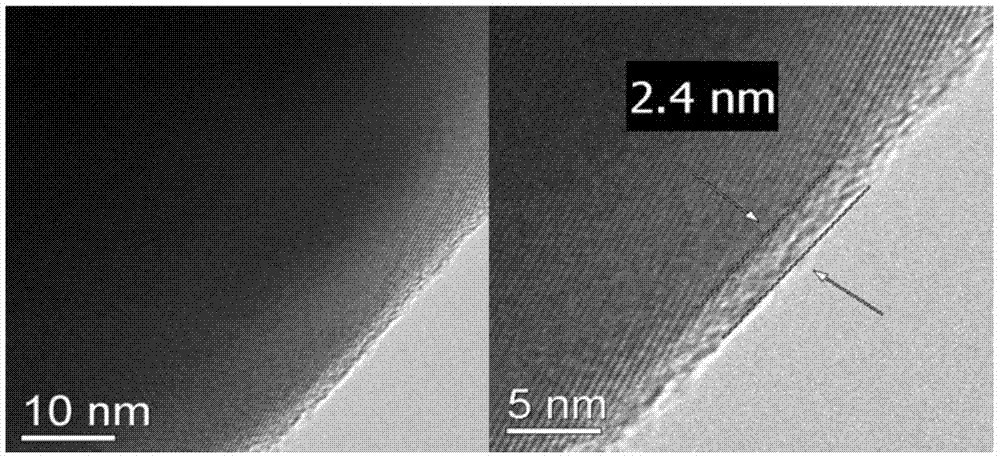

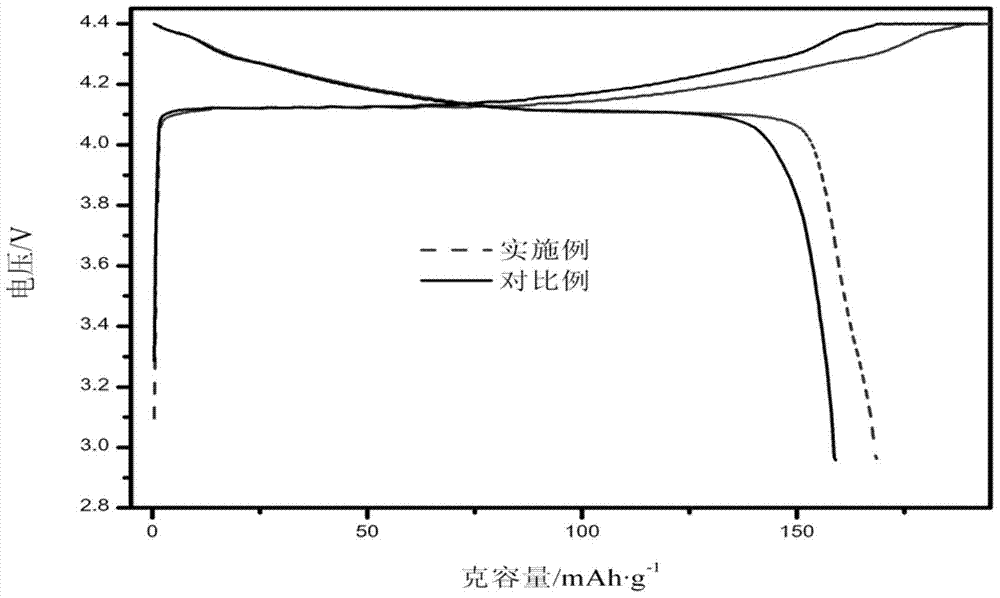

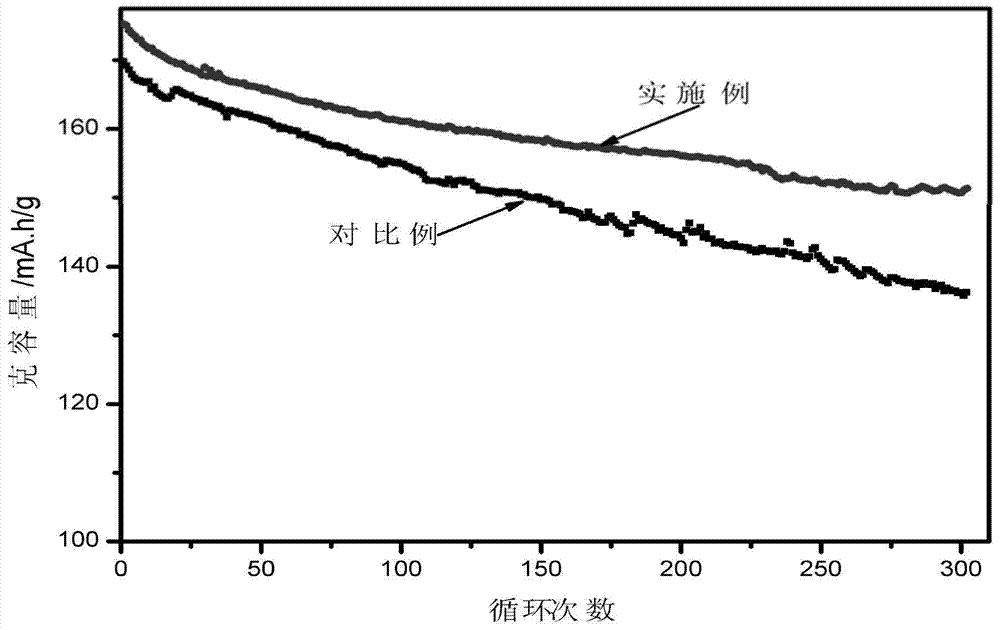

[0027] with TiO 2 , Li 2 CO 3 and Co 3 o 4 As the raw material, the molar ratio of substances is n(TiO 2 ):n(Li 2 CO 3 ):n(Co 3 o 4 )=0.005:0.5:0.995 After mixing with a high-efficiency mixer, calcination at 1000°C for 6 hours to obtain Ti-doped LiCo 0.995 Ti 0.005 o 2 Matrix A (particle size D 50 is 12 μm). With Li 2 CO 3 and Ni 0.6 co 0.2 mn 0.2 (OH) 2 The precursor is the raw material, and the molar ratio of the substances is n(Li 2 CO 3 ):n(Ni 0.6 co 0.2 mn 0.2 (OH) 2 )=0.5:1 After mixing with a high-efficiency mixer, calcination at 1000°C for 6 hours to synthesize LiNi 0.6 co 0.2 mn 0.2 o 2 Matrix B (particle size D 50 is 6 μm). Substrate A: Substrate B: Flux (flux is MgO and LiF, the mass ratio is 1:1) mass ratio = 50:50:0.08, mixed with a high-efficiency mixer for 30 minutes, and then added to account for the total mass of matrix A and matrix B 0.5% PVDF NMP solution (solid content: 10%), dispersed and kneaded for 1 hour, then calcined at 1...

Embodiment 2

[0029] With MgO, Li 2 CO 3 and Co 3 o 4 As raw material, the material molar ratio is n(MgO):n(Li 2 CO 3 ):n(Co 3 o 4 )=0.002:0.5:0.998, mixed with a high-efficiency mixer, and then fired at 1000°C for 10 hours to obtain Mg-doped LiCo 0.998 Mg 0.002 o 2 Matrix A (particle size D 50 15-16μm). With Li 2 CO 3 and Ni 0.6 co 0.2 mn 0.2 (OH) 2 The precursor is the raw material, and the molar ratio of the substances is n(Li 2 CO 3 ):n(Ni 0.6 co 0.2 mn 0.2 (OH) 2 )=0.5:1 After mixing with a high-efficiency mixer, calcining at 900°C for 8 hours to synthesize LiNi 0.6 co 0.2 mn 0.2 o 2 Matrix B (particle size D 50 6-7μm). Substrate A: Substrate B: Flux (TiO 2 with MgF 2 , the mass ratio is 1:1) mass ratio = 50:50:0.08, first mix with a high-efficiency mixer for 30 minutes, then add 0.5% PVDF NMP solution (solid content is 10%), disperse and knead for 1 hour and then heat at 900 ° C Roasting 12h. Using aluminum nitrate as the coating source, through a wet pr...

Embodiment 3

[0031] With CeO 2 , Li 2 CO 3 and Co 3 o 4 As the raw material, the molar ratio of substances is n(CeO 2 ):n(Li 2 CO 3 ):n(Co 3 o 4 )=0.1:0.5:0.9, mixed with a high-efficiency mixer, and then fired at 700°C for 10 hours to obtain Ce-doped LiCo 0.9 Ce 0.1 o 2Matrix A (particle size D 50 6-8μm). With Li 2 CO 3 and Ni 0.6 co 0.2 mn 0.2 (OH) 2 The precursor is the raw material, and the molar ratio of the substances is n(Li 2 CO 3 ):n(Ni 0.6 co 0.2 mn 0.2 (OH) 2 )=0.5:1 After mixing with a high-efficiency mixer, calcination at 950°C for 10 hours to synthesize LiNi 0.6 co 0.2 mn 0.2 o 2 Matrix B (particle size D 50 12-14μm). Substrate A: Substrate B: Flux (TiO 2 With LiF, the mass ratio is 1:1) mass ratio = 60:40:0.1, first mix with a high-efficiency mixer for 30 minutes, then add 0.5% PVDF NMP solution (solid content is 10%), disperse and knead for 1 hour at 950 ° C Roasting at high temperature for 10h. Finally, the liquid phase method was used to co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com