IGBT device and manufacturing method thereof

A device and drift region technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as reduction of on-state voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] As mentioned in the background section, in order to reduce the conduction loss of the IGBT, it is necessary to further reduce its conduction voltage drop.

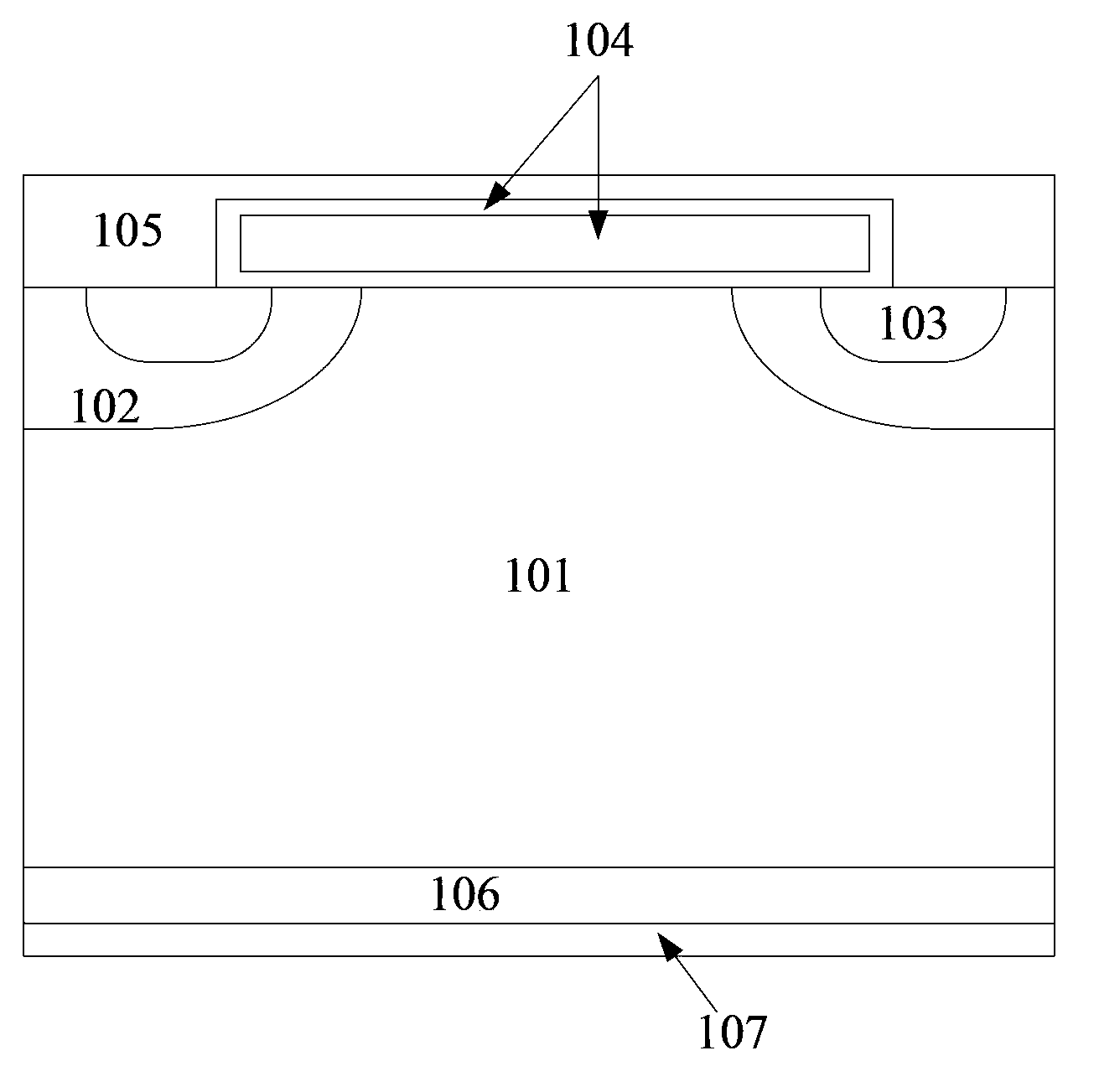

[0046] Taking the IGBT device with N-type planar gate structure as an example, it is divided into punch-through IGBT and non-punch-through IGBT, such as figure 1 as shown, figure 1 It is a structural schematic diagram of the non-punch-through IGBT device, including:

[0047] N-type lightly doped (N-) substrate, which includes: N-drift region 101, P-type well region 102 (generally P-type lightly doped) located on both shoulders of the drift region 101, and located on the N-type heavily doped (N+) source region 103 in the P-type well region 102;

[0048] a gate structure 104 on the surface of the substrate;

[0049] The source electrode 105 located on the surfaces of the well region 102 and the source region 103;

[0050] P-type heavily doped (P+) collector region 106 located in the lower surface of the substrate;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com