Power cable for nuclear power plant

A technology for power cables and nuclear power plants, applied in the field of power cables for nuclear power plants, can solve problems such as fire resistance and corrosion resistance, and achieve the effects of low pH value and electrical conductivity, excellent flame retardant performance, and less smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

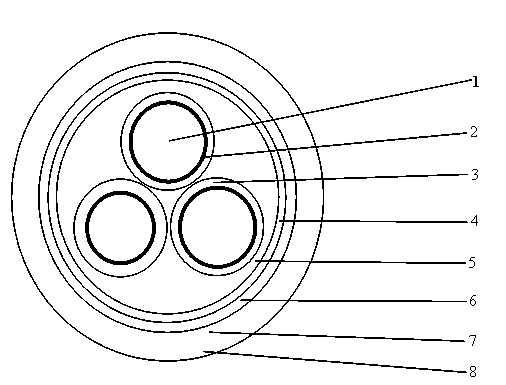

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] A power cable for nuclear power plants, including three conductors 1 (the cross-sectional area of the conductors is 1.5-300mm 2 ), insulating layer 3, the outer sides of the three conductors 1 are respectively wrapped with a refractory layer 2 and an insulating layer 3, and after wrapping the insulating layer 2, the three conductors 1 are mutually twisted into a bundle, and the outer side of the insulating layer 3 is wrapped with a tape layer 4, and the tape Magnesium hydroxide is set between the layer 4 and the insulating layer 3 as the filling layer 5, and the outer side of the tape layer 4 is wrapped with an inner lining layer 6 and an armor layer 7. The armor layer 7 is made of galvanized steel strip, and the outer side of the armor layer 7 is Wrapped with a high flame-retardant, low-smoke, halogen-free, radiation-proof, and ozone-resistant polyolefin shea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com