Alkane foam b1-level flame-retardant polyurethane rigid foam and preparation method thereof

A technology of rigid foam and alkane, which is applied in the field of alkane foaming B1 flame-retardant polyurethane rigid foam and its preparation, can solve the problems of high brittleness of polyurethane foam, difficulty in large-scale use, poor thermal insulation performance, etc., and achieve Low cost, convenient technological operation, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

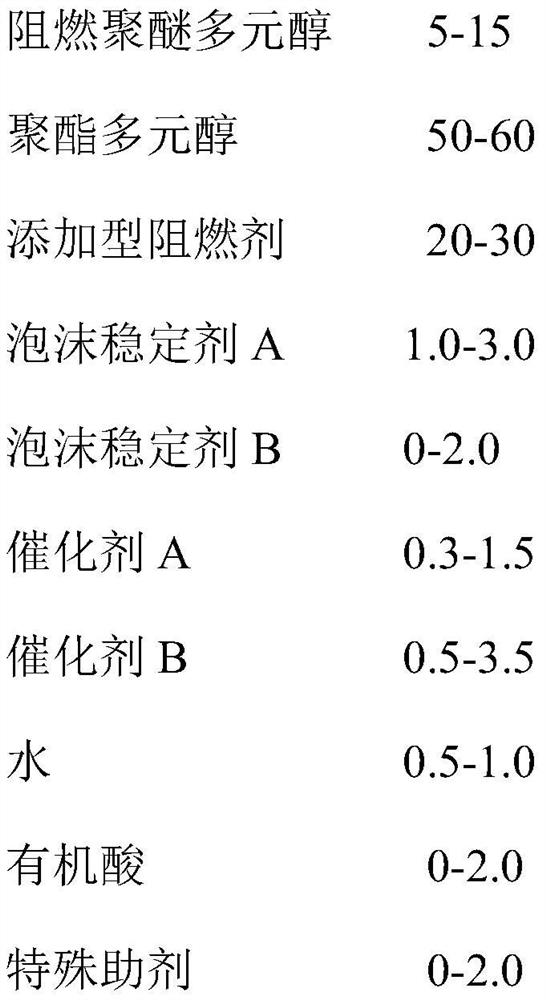

[0039] The formula system is as follows:

[0040] Combination polyether polyol components: 100 Flame Retardant Polyether Polyol 1 10 Polyester Polyol 1 57.6 TCPP 25 Foam Stabilizer A1 1.5 Foam Stabilizer B1 0.5 PC5 0.5 PC8 0.8 Potassium acetate 2.5 water 0.6 acetic acid 1 Blowing agent components: n-pentane 6 Polyisocyanate component: PM-400 210

[0041] Flame retardant polyether polyol 1, tetrabromobisphenol A as initiator, hydroxyl value of 112mgKOH / g, Wanhua Chemical (Ningbo) Rongwei Polyurethane Co., Ltd., product brand FR212.

[0042] Polyester polyol 1, phthalic anhydride OPA, terephthalic acid, adipic acid and diethylene glycol DEG, glycerol polymerization, hydroxyl value 190mgKOH / g, Beijing Demei Science and Technology Co., Ltd., product brand DM2013 .

[0043] Foam Stabilizer A1, Evonik Specialty Chemicals (Shanghai) Co., Ltd., B84813.

[0044] Foam Stabilizer A2, Evo...

Embodiment 2

[0047] The formula system is as follows:

[0048] Combination polyether polyol components: 100 Flame Retardant Polyether Polyol 2 12 Polyester Polyol 2 50 TCPP 25 TEP 5 Foam Stabilizer A2 3 PC5 0.3 PC8 0.5 Potassium formate 2.5 water 0.5 Formic acid 1.2 Blowing agent components: n-pentane 5 Polyisocyanate component: PM-700 230

[0049] Flame retardant polyether polyol 2, prepared by the ring-opening reaction of a mixed initiator of glycerol and melamine with ethylene oxide, the mass ratio of glycerol and melamine is 5:1, and the hydroxyl value range is 480mgKOH / g. Wanhua Chemical ( Ningbo) Rongwei Polyurethane Co., Ltd.

[0050] Polyester polyol 2, phthalic anhydride OPA, terephthalic acid and diethylene glycol DEG, glycerol polymerized, the hydroxyl value is 315mgKOH / g, Stepan Polyester Co., Ltd., product brand PS3158.

[0051] Foam Stabilizer A2, Evonik Specialty Chemicals (S...

Embodiment 3

[0054] The formula system is as follows:

[0055]

[0056]

[0057] Flame retardant polyether polyol 1, tetrabromobisphenol A as initiator, hydroxyl value of 112mgKOH / g, Wanhua Chemical (Ningbo) Rongwei Polyurethane Co., Ltd., product brand FR212.

[0058] Flame retardant polyether polyol 3, prepared by a ring-opening reaction of a mixed initiator of glycerol and melamine with ethylene oxide, the mass ratio of glycerol and melamine is 3:1, and the hydroxyl value range is 350mgKOH / g. Wanhua Chemical ( Ningbo) Rongwei Polyurethane Co., Ltd.

[0059] Polyester polyol 3, phthalic anhydride OPA, terephthalic acid, adipic acid and diethylene glycol DEG, polymerized, the hydroxyl value is 200mgKOH / g, Stepan Polyester Co., Ltd., product brand DPR5145- 36.

[0060] Foam Stabilizer A1, Evonik Specialty Chemicals (Shanghai) Co., Ltd., B84813.

[0061] Foam Stabilizer A2, Evonik Specialty Chemicals (Shanghai) Co., Ltd., B8443.

[0062] Alcohol ester acid is 2-[2-(2-hydroxyethoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| heat release | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com