Tensioner for repairing lined oil pipe and its repairing process

A tensioner and tubing technology, applied in wellbore/well components, earthwork drilling, etc., can solve problems such as thread damage, flanging damage and cost, and achieve the effect of reducing investment, saving money, and good experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

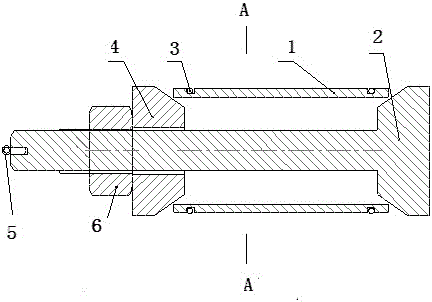

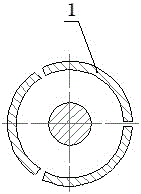

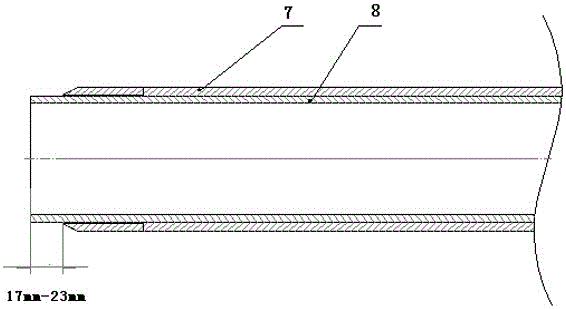

[0020] The present invention is described in detail below in conjunction with accompanying drawing, not limiting protection scope of the present invention, see figure 1 and figure 2 , The tensioner for repairing the lined oil pipe includes a tensioner 1, a spring steel ring 3 and a tensioning mechanism, and the tensioner 1 is closed on the connecting rod 2 of the tensioning mechanism by 3 turns of the spring steel ring. The tightening mechanism includes a connecting rod 2, a pusher block 4 and a tightening nut 6. One end of the connecting rod 2 is a stopper, and the other end of the rod body is provided with a threaded pusher block 4 and a tightening nut 6. The tensioner 1 is placed on the connecting rod 2 between the block seat and the propelling block 4. The block seat of the propulsion block 4 and the connecting rod 2 is a tapered structure, and the propulsion block 4 is provided with a central hole to be sleeved on the rod body of the connecting rod 2, and the small end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com