Inward clamping device for clamping composite oil pipe lining

A composite oil pipe and oil pipe technology, which is applied in the direction of thread trimmer, expanding mandrel, thread trimming device, etc., can solve the problems of thread damage and flanging damage cost, save time and labor, reduce processing costs, and make up for repair costs. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

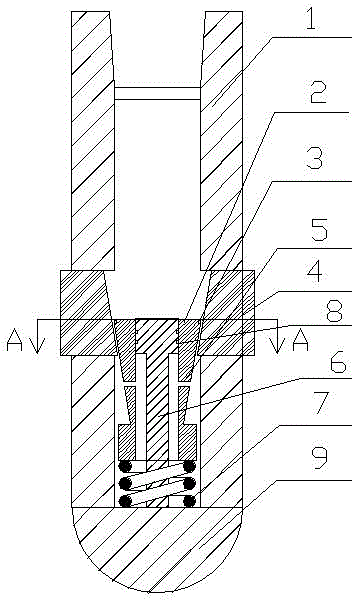

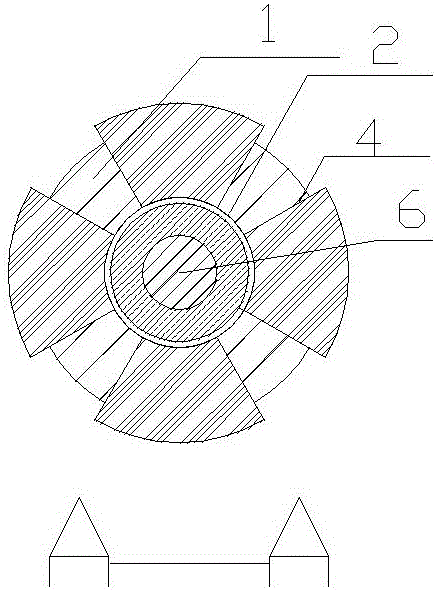

[0021] The present invention is described in detail below in conjunction with accompanying drawing, not limiting protection scope of the present invention, see figure 1 , figure 2 and image 3 , an internal tightener for composite oil pipes, including a main body 1, a pushing piston 2, a sealing ring I3, a tightening block 4, a lubricating hole 5, a sliding sealing piston rod 6, a spring 7, a sealing ring II 8, a guide head 9, the main body 1. The lower end is connected to the guide head 9, and the sliding sealing sleeve in the main body 1 is equipped with a pushing piston 2, and the outer wall of the pushing piston 2 is provided with a plurality of inclined-plane grooves; on the wall of the main body 1, there are A plurality of radial windows, each radial window has a fastening block 4, the inclination of the inner side slope of the fastening block 4 is the same as the slope groove on the pushing piston 2 and can be slid relative to each other; the high-pressure fluid acts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com