Carding roller used for machining Teflon ultra thin and short fiber

A polytetrafluoroethylene and short fiber technology, which is applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of uneven fineness, long preparation process, coarse fiber fineness, etc. The effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

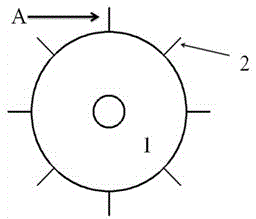

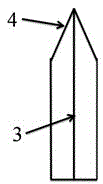

[0024] Such as Figure 5 As shown, the unwinding machine is used to feed the PTFE uniaxially stretched film into the starting position of the carding roller through the front guide roller, through the carding roller slitting blade, and after slitting, it is introduced into the winding through the rear guide roller machine and rewind.

[0025] The carding roller adopts a slitting blade with a thickness of 0.1mm, and 16 rows of slitting blades are arranged in each cycle on the surface of the carding roller. The PTFE uniaxially stretched film passes through the carding roller to form a polytetrafluoroethylene with a fineness of 0.6dtex. Vinyl fluoride staple fiber.

Embodiment 2

[0027] Such as Figure 5 As shown, the unwinding machine is used to feed the PTFE uniaxially stretched film into the starting position of the carding roller through the front guide roller, through the carding roller slitting blade, and after slitting, it is introduced into the winding through the rear guide roller machine and rewind.

[0028] The carding roller adopts a slitting blade with a thickness of 0.2 mm, and 32 rows of slitting blades are arranged in each cycle on the surface of the carding roller. The polytetrafluoroethylene uniaxially stretched film passes through the carding roller to form a polytetrafluoroethylene with a fineness of 0.6dtex. Vinyl fluoride staple fiber.

Embodiment 3

[0030] Such as Figure 5 As shown, the unwinding machine is used to feed the PTFE uniaxially stretched film into the starting position of the carding roller through the front guide roller, through the carding roller slitting blade, and after slitting, it is introduced into the winding through the rear guide roller machine and rewind.

[0031] The carding roller adopts a slitting blade with a thickness of 0.1 mm, and 32 rows of slitting blades are arranged in each cycle on the surface of the carding roller. The PTFE unidirectional stretch film forms a polytetrafluoroethylene film with a fineness of 0.3 dtex after passing through the carding roller. Vinyl fluoride staple fiber.

[0032] In the three embodiments, the polytetrafluoroethylene uniaxially stretched film must pass through more than one slitting blades arranged in a cycle to ensure the uniformity of the polytetrafluoroethylene short fibers.

[0033] The fineness of the PTFE staple fiber can be controlled by the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com