Organic fertilizer made of fermented sable dung and preparation method thereof

A technology of organic fertilizer and fermentation bacteria, applied in the field of organic fertilizer, can solve problems such as hidden dangers of plants, and achieve the effects of improving crop properties, reducing environmental pollution, and improving the quality of agricultural products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

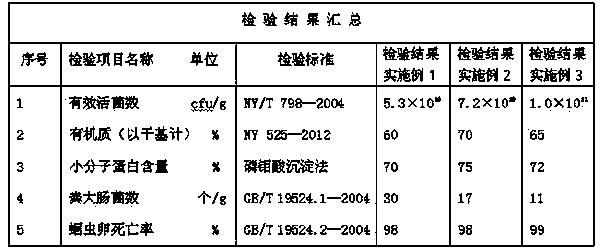

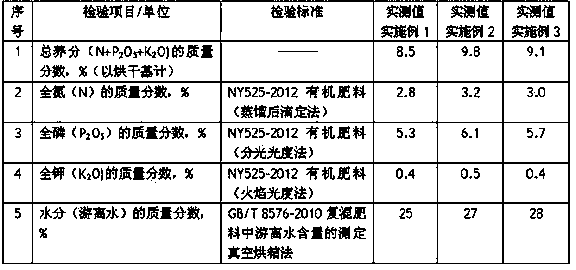

Embodiment 1

[0024] Mix 1kg of fermented fermented mink manure, 50kg of wheat bran, and 50kg of rice bran, mix the mixed material with water at a ratio of 1:0.5, stack and compact, seal and ferment with plastic film or canvas. After 9 days, the aroma of distiller's yeast and white and red mycelium appeared, and the effective bacteria content was 5 billion per gram; under the condition of ventilation on the scaffolding on the cement floor, use a forklift to mix the fermented materials with 500kg of mink manure and 500kg of edible fungi Bacteria chaff is mixed and piled into a pile with a height of 1.5 meters, a width of 2 meters, and an unlimited length. Start to accumulate and ferment. The initial moisture content of the fermentation material is 28%. At 65°C, use a forklift to turn the pile; ferment for 15 days, at this time, the water content of the fermented material gradually decreases with the maturity of the fermentation. At the end of the fermentation, the temperature drops below 30°C...

Embodiment 2

[0027] Mix 5kg of fermented fermented mink manure, 50kg of wheat bran, and 50kg of rice bran, mix the mixed material with water at a ratio of 1:0.8, mix well, stack and compact, seal and ferment with plastic film or canvas. After 7 days, the aroma of distiller's yeast and white and red mycelia appear, and the effective bacteria content is 10 billion per gram; under the condition of ventilated scaffolding on the cement floor, use a forklift to mix the fermented material with 700kg of mink manure and 300kg of edible Bacteria and chaff are mixed and piled into a pile with a height of 2 meters, a width of 2.5 meters, and an unlimited length. Start to pile up and ferment. The initial moisture content of the fermentation material is 28%; 25-65°C temperature-controlled fermentation, every 12-36 hours or the temperature rise of the fermentation pile When the temperature exceeds 65°C, turn over with a forklift; ferment for 10 days, at this time, the water content of the fermented ma...

Embodiment 3

[0029]Mix 10kg of fermented fermented mink manure, 80kg of wheat bran, and 80kg of rice bran, mix the mixed material with water at a ratio of 1:0.7, mix well, stack and compact, seal and ferment with plastic film or canvas, and pass through After 7 days, the aroma of distiller's yeast and white and red mycelium appeared, and the effective bacteria content was 8 billion per gram; under the condition of ventilation on the concrete floor scaffolding, use a forklift to mix the fermented materials with 600kg of mink manure and 400kg of edible fungi Bacteria chaff is mixed and piled into a material pile with a height of 1.5 meters, a width of 3 meters and an unlimited length. The pile starts to accumulate and ferment. The initial water content of the fermentation material is 30%. At 65°C, use a forklift to turn the pile; ferment for 20 days, at this time, the water content of the fermented material gradually decreases with the maturity of the fermentation. %, pH value 6.0, small mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com