Feeding device for thickener and mounting method thereof

A technology of feeding device and thickener, which is applied to the feeding/discharging device of sedimentation tank, separation method, chemical instrument and method, etc. It can improve the utilization rate of tailings, improve the mixing uniformity, and avoid the overflow water running and mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

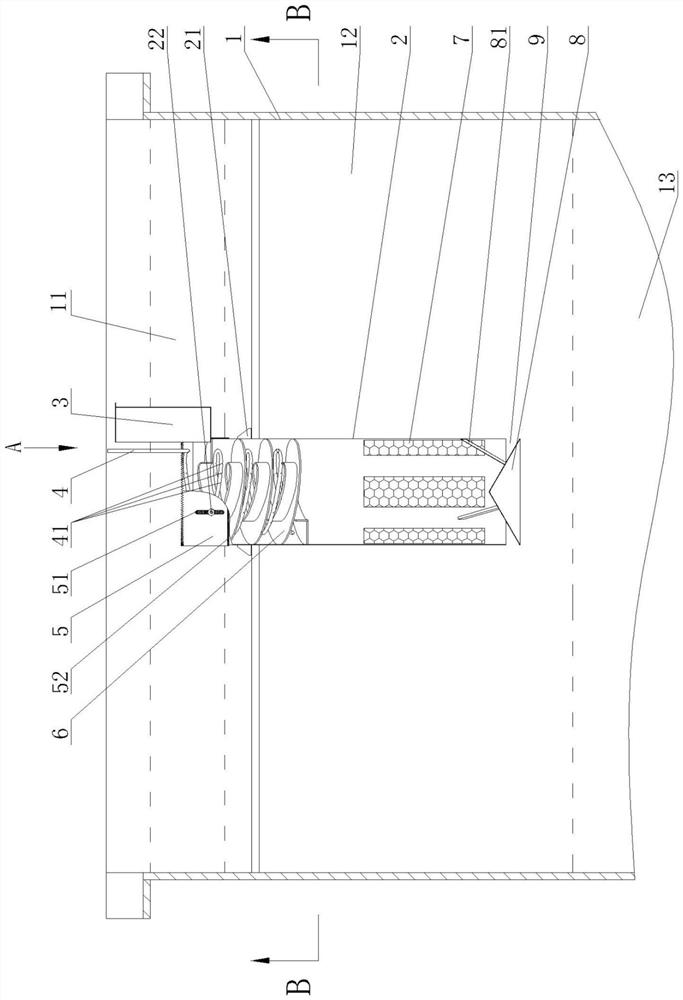

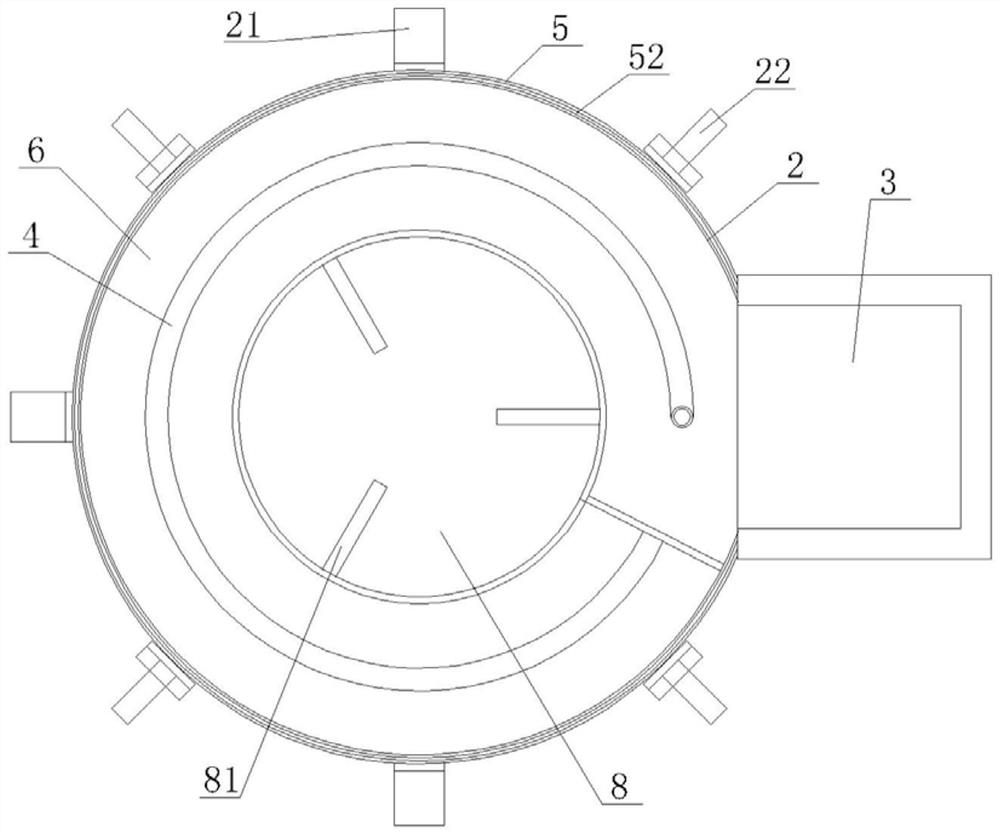

[0042] from Figure 1 to Figure 3 It can be seen that the feeding device for the thickener of the present invention includes a feeding cylinder 2, a feeding trough 3, an adding pipe 4, a self-diluting baffle 5, a spiral guide chute 6, a filter cloth 7 and a conical splitter. Tray 8;

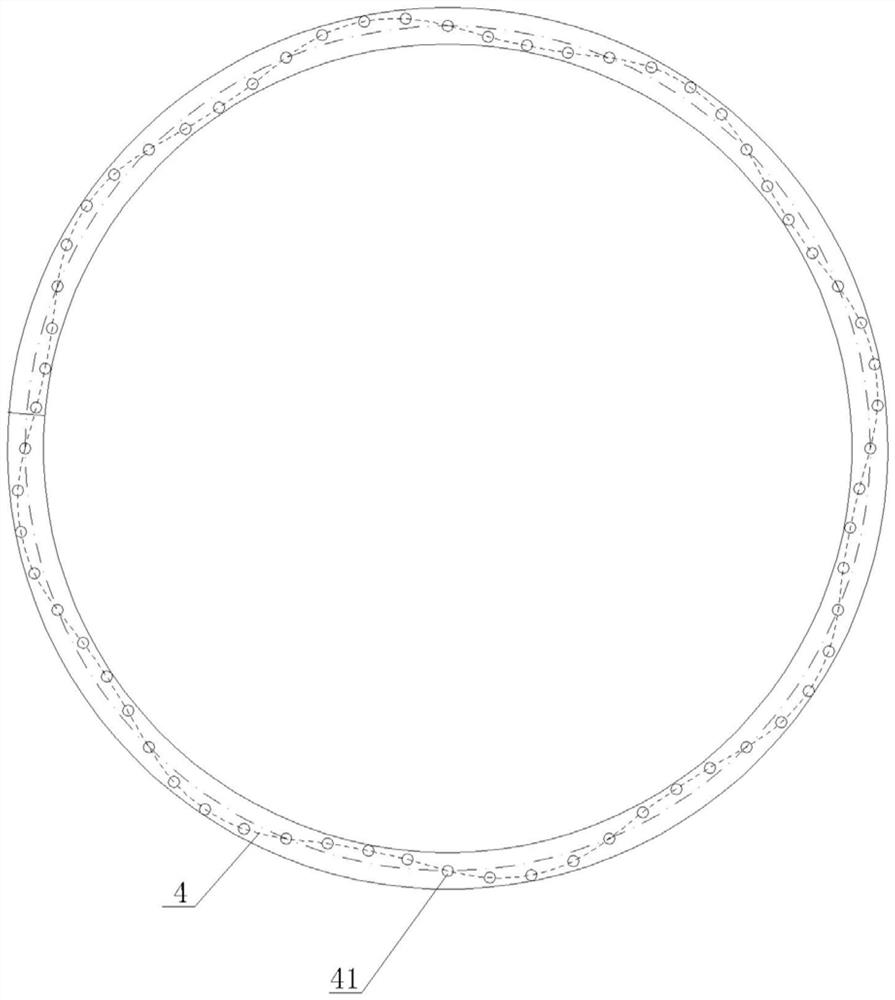

[0043] The feed cylinder 2 is erected in the thickener body 1 through the hanging lugs 21 provided on the cylinder wall. The interior of the thickener body 1 includes a clarification zone 11, a settling zone 12 and a compression zone 13 arranged sequentially from top to bottom. The top surface of the feeding barrel 2 is located at the lower boundary of the clarification zone 11, and four screws 22 arranged radially along the feeding barrel 2 are welded on the wall of the feeding barrel 2 top, and the four screws 22 are arranged along the feeding barrel 2. Evenly distributed in the circumferential direction;

[0044] The feeding chute 3 is welded on the feeding cylinder 2 between two adjacent sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com