A bioelectrochemical reactor for treating organic fluorine wastewater and a treatment method for organic fluorine wastewater

A bioelectrochemical and reactor technology, which is applied in chemical instruments and methods, water pollutants, biological water/sewage treatment, etc. The effect of removing and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

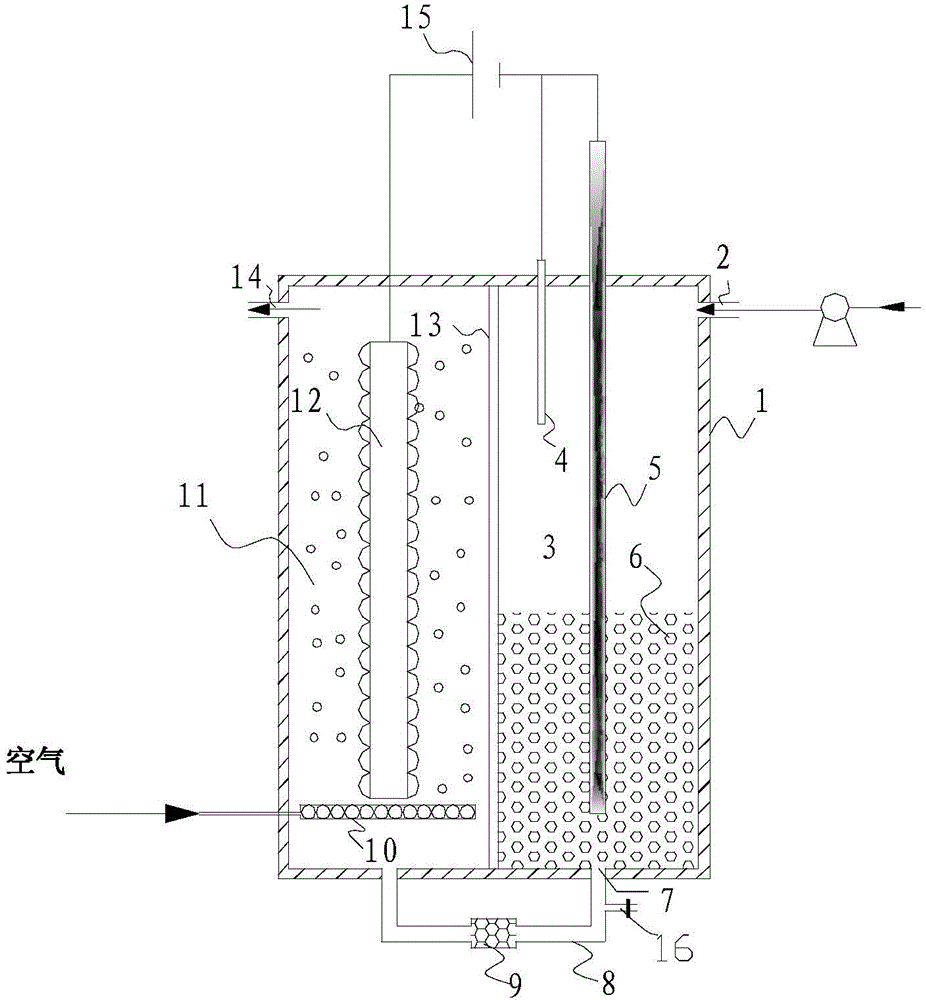

[0067] In the bioelectrochemical reactor in the present embodiment, the cathode chamber 3 and the anode chamber 11 are cubic chambers made of plexiglass, and the length, width and height of the cathode and anode chambers are respectively 10cm*10cm*15cm, and the cathode chamber is loaded with microorganisms. The filling rate of the microbial carrier 6 in the cathode chamber 3 is 50%, and the effective reaction volumes of the cathode and anode chambers are 0.7L and 1.4L respectively. The partition 13 between the cathode chamber and the anode chamber is made of plexiglass, and the conduit 8 connecting the two chambers is a PVC plastic pipe with a diameter of 1 cm.

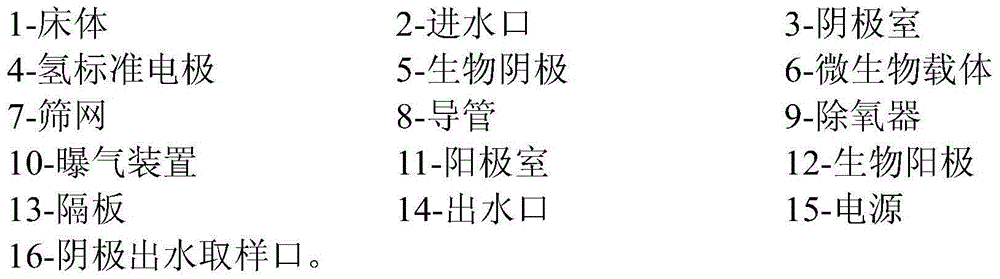

[0068] Treat the simulated wastewater with 2-fluoroaniline as the simulated pollutant with the bioelectrochemical reactor for the treatment of organic fluorine wastewater provided by this example, and compare it with the separate electrochemical method and the separate biological method. In the treated simulated wastew...

Embodiment 2

[0073] The bioelectrochemical reactor of the present embodiment is the same as that of Example 1, and the simulated waste water with 4-fluoronitrobenzene as the simulated pollutant is treated with this reactor, compared with independent electrochemical treatment and microbial treatment, the processed The concentration of 4-fluoronitrobenzene contained in the simulated wastewater is 75mg / L, and the concentration of sucrose contained is 200mg / L. The hydraulic retention time of the wastewater in the electrochemical reactor is 16h. The treatment effects of the three methods are shown in Table 2 Shown:

[0074] Table 2:

[0075]

Embodiment 3

[0076] Example 3 The bioelectrochemical reactor in this example is the same as in Example 1, and this reactor is used to treat the production wastewater of an organic fluorine chemical enterprise: the COD content of the wastewater is 550mg / L, and the biochemical property is poor (B / C=0.175) , the specific type of organic fluorine contained in the wastewater is unknown. The waste water treatment effect of this embodiment is compared with independent electrochemical treatment and microbial treatment effect as shown in table 3:

[0077] table 3

[0078]

[0079]As can be seen from the comparative results of the above three examples, the reactor of the present invention combined with the treatment method of the present invention to treat organic fluorine wastewater has greatly improved the treatment effect of organic fluorine wastewater compared with traditional electrochemical methods or biological methods, and the quality of effluent discharge has further improved. improve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com