Repair method of working ability of diamond drill bit

The technology of a diamond drill bit and repair method, which is applied in the field of diamond drill working ability repair, can solve the problems of reducing the structural size of the original drill bit, which is not conducive to the life of the drill bit, and the diamond drill bit cannot be welded, so as to increase the drilling footage and ensure the firmness of the drill bit. , the effect of filling the gaps in the repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

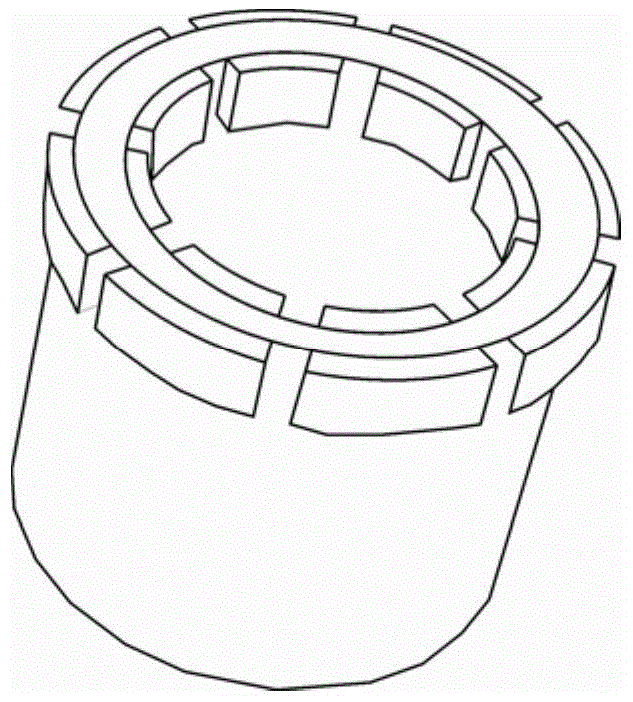

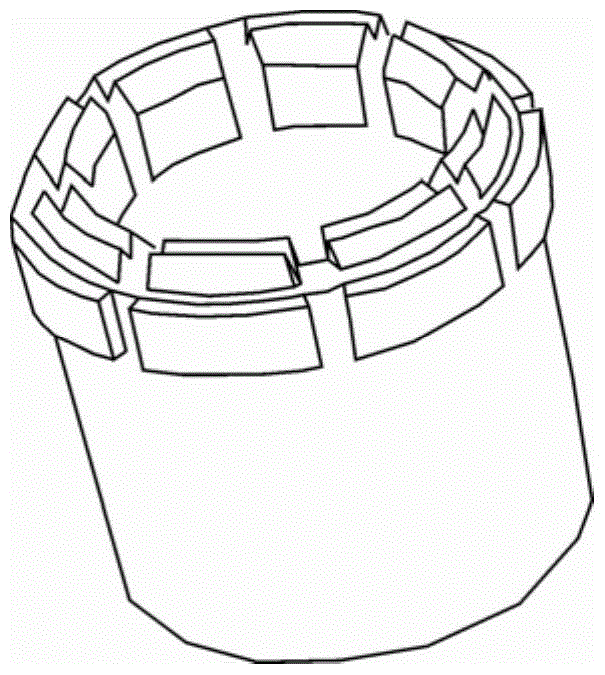

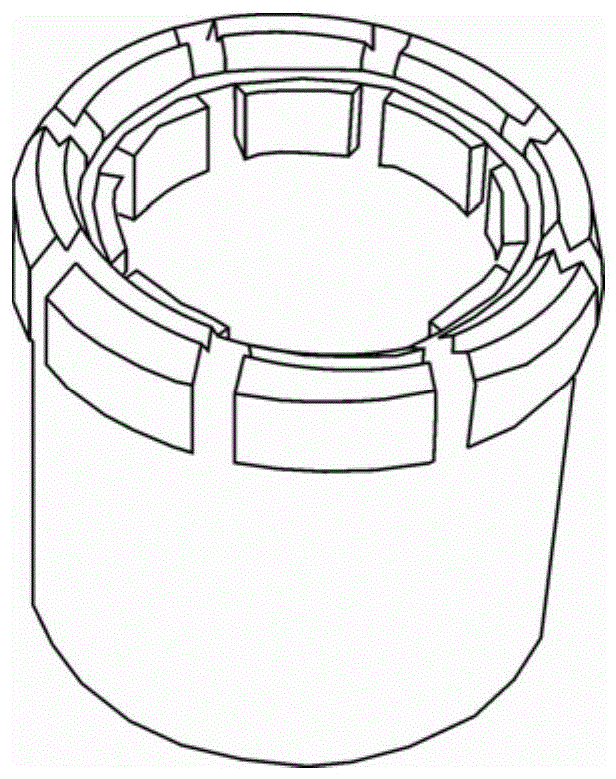

[0027] refer to Figure 1~Figure 5 Shown, the diamond drill working ability repairing method of the present invention, comprises the following steps:

[0028] a) After the diamond bit is lifted to the surface, first check whether there is any abnormal wear part 2 on the diamond bit that affects the continued use of the drill bit, and if so, determine the volume to be repaired of the abnormal wear part 2 of the diamond bit, and the abnormal wear part 2 Including abrasive wear parts such as lip polishing, grooving, chamfering and shedding of diamond bits, such as Figure 1~Figure 3 As shown; after determining the volume to be repaired at the abnormally worn part 2 of the drill bit, prepare a diamond-containing composite material repair layer 3 that is similar in composition to the diamond bit matrix 1 and consistent with the diamond concentration requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com