Pneumatic particle separator, and fluidized bed reactor and its application

A technology for fluidized bed reactors and separators, which is applied in chemical instruments and methods, devices in which the axial direction of the swirl can be reversed, swirl devices, etc., and can solve the problem of low fine powder entrainment and low separation efficiency. problem, to achieve the effect of low flow rate, low probability of secondary crushing, and reduced probability of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

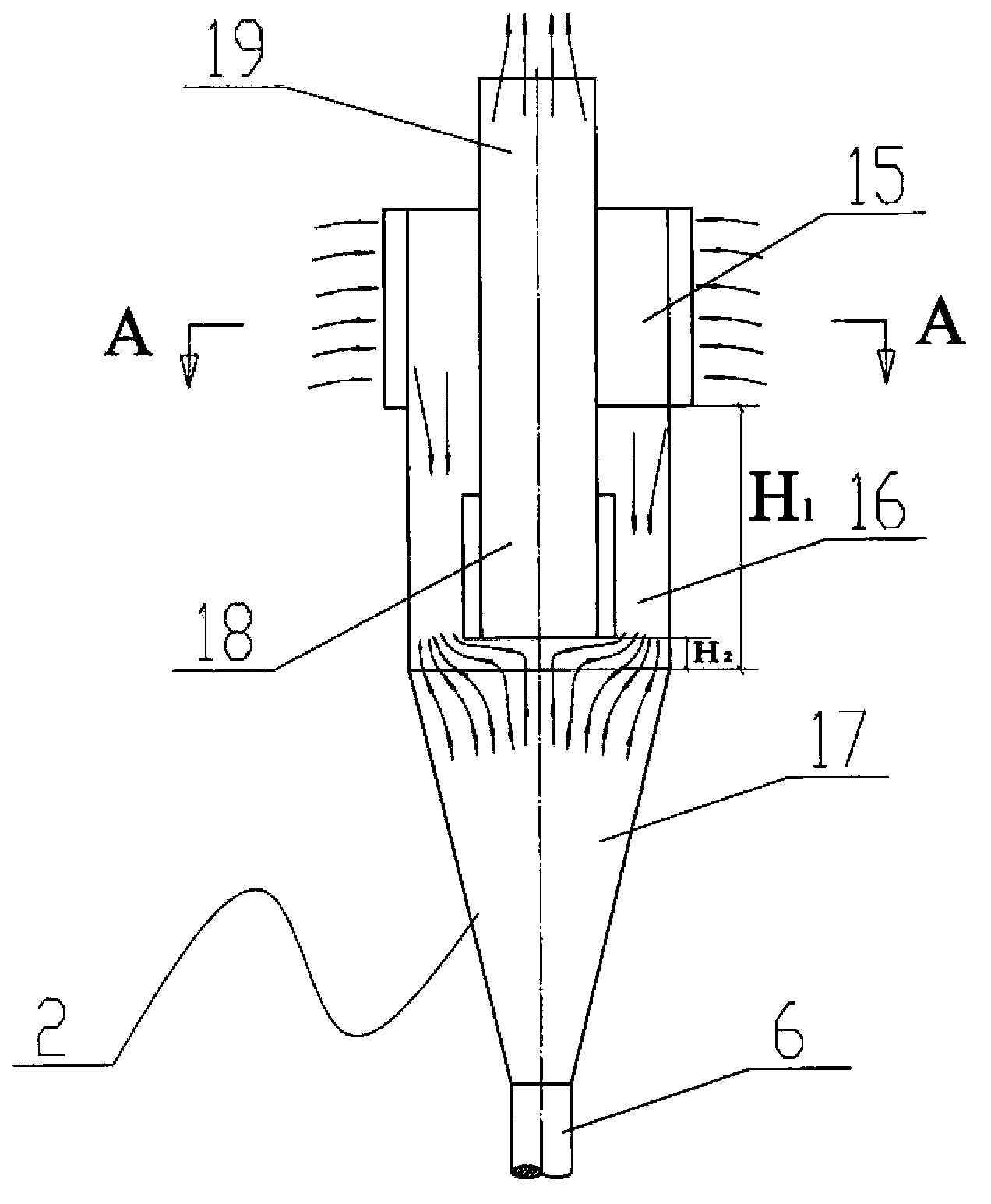

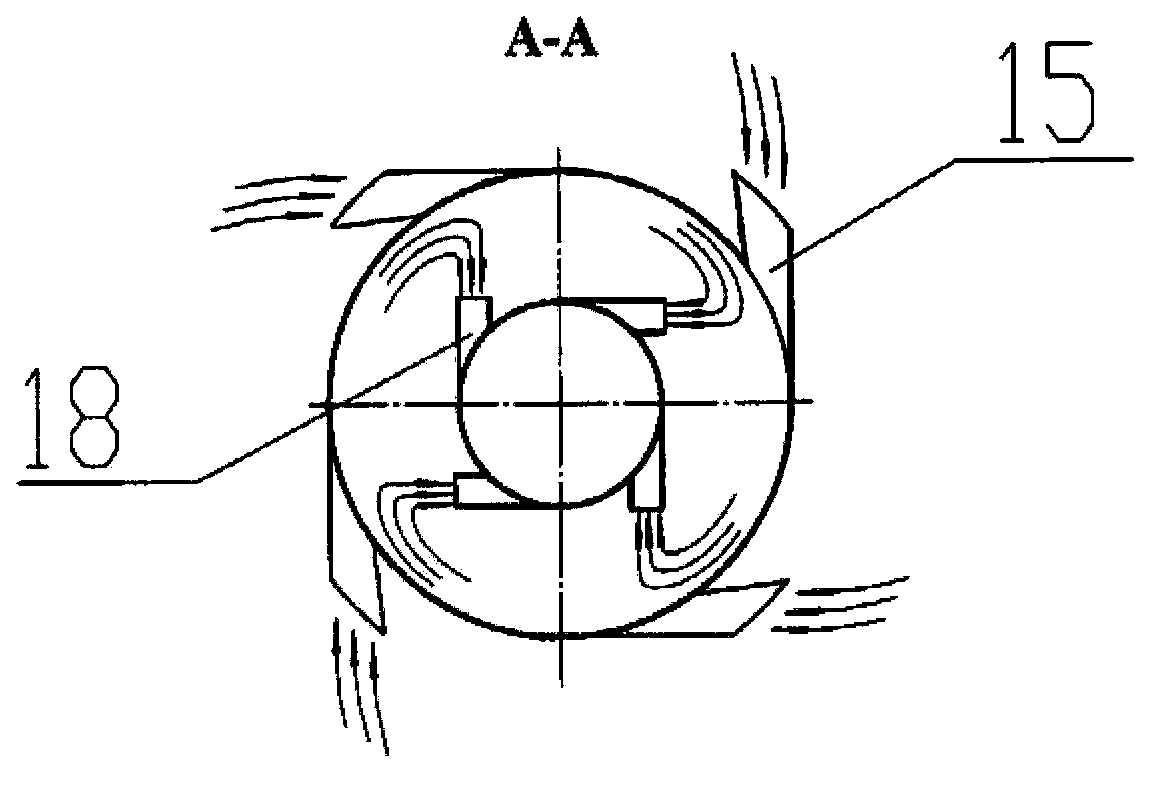

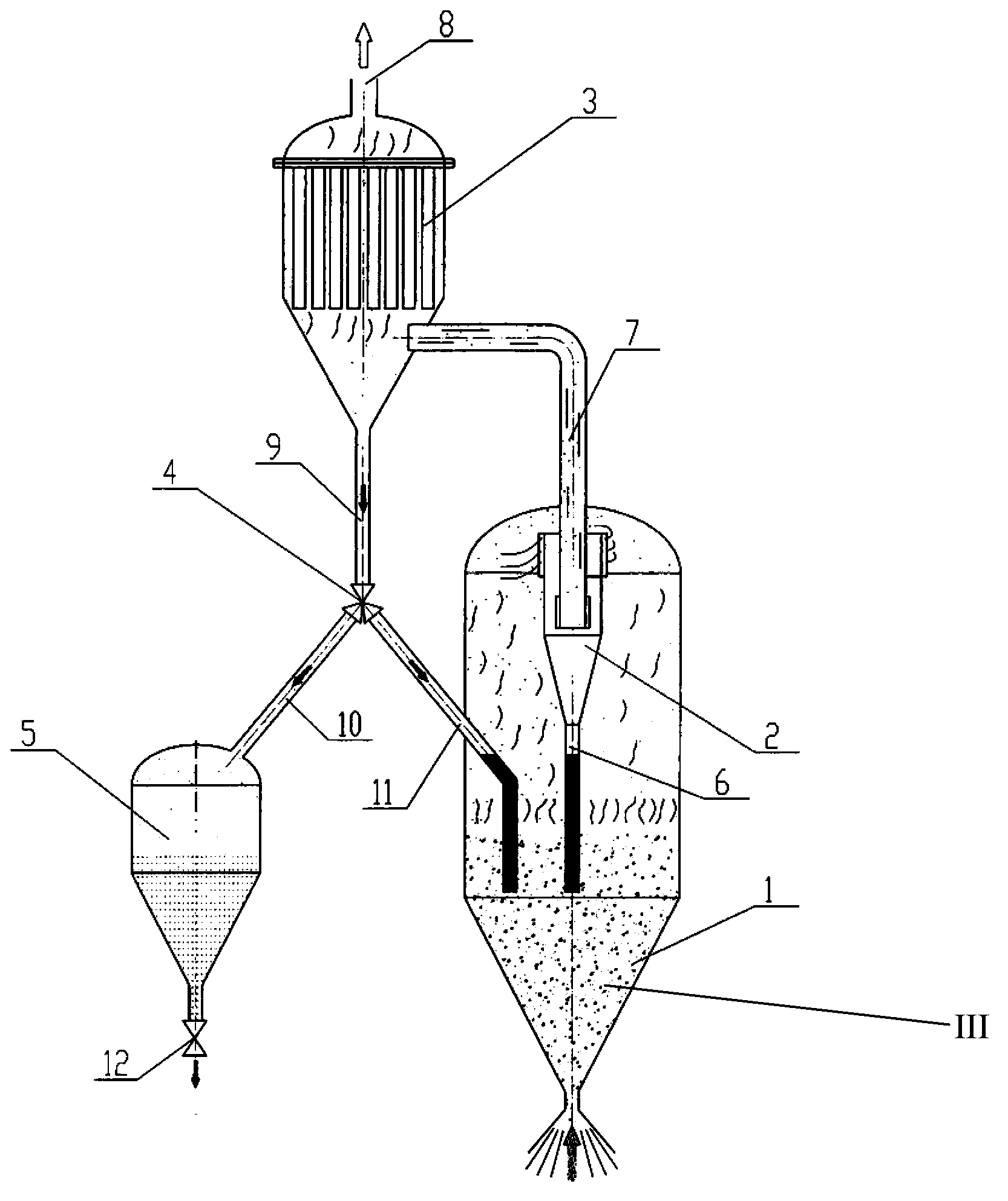

[0092] In this embodiment, four guiding air inlets (such as figure 2 As shown, the guide air inlet is set along the circumference of the straight cylinder area, and each guide air inlet has the same cross-sectional area perpendicular to the airflow direction), and three guides are arranged tangentially on the air outlet pipe of the airflow particle separator air outlet (such as figure 2 As shown, the guide air outlet is set along the circumference of the air outlet pipe, and the area of each guide air outlet perpendicular to the air flow direction section is the same); the difference between the area of the horizontal section of the straight barrel area and the area of the horizontal section of the air outlet pipe for A 0 , the total area of the cross-section perpendicular to the air flow directed to the air inlet is A 1 , the total area of the cross-section perpendicular to the air flow directed to the air outlet is A 2 , A 1 / A 0 0.4:1, A 2 / A 0 is 0.2:1; ...

Embodiment 2

[0107] Adopt the method identical with embodiment 1 to carry out adsorption desulfurization, difference is, A 1 / A 0 0.24:1, A 2 / A 0 is 0.15:1, the linear velocity of the oil mixture at the guide air inlet of the airflow particle separator is 2.5m / s, and the linear velocity at the guide air outlet of the airflow particle separator is 4m / s.

[0108] Continuously for 500 hours. During the reaction, the composition of the obtained oil and gas product and the average particle size of the catalyst in the catalyst fine powder storage tank and the catalyst dense bed in the fluidized bed reactor were monitored, and the results are listed in Table 4. After reacting for 500 hours, the content of the catalyst with a particle size of less than 30 μm in the catalyst in the dense-phase bed in the fluidized bed reactor was 9.5% by weight. A total of 14.2kg of catalyst was loaded in the fluidized bed reactor before the reaction started, and 1.34kg of catalyst was added to the fluidized b...

Embodiment 3

[0124] Adopt the method identical with embodiment 1 to carry out adsorption desulfurization, difference is:

[0125] There are 6 guiding air inlets (such as figure 2 As shown, the guide air inlet is arranged along the circumference of the straight cylinder area, and each guide air inlet has the same cross-sectional area perpendicular to the air flow direction), and 6 guide guides are arranged tangentially on the air outlet pipe of the airflow particle separator air outlet (such as figure 2 As shown, the guide air outlet is set along the circumference of the air outlet pipe, and the area of each guide air outlet perpendicular to the air flow direction section is the same); the difference between the area of the horizontal section of the straight barrel area and the area of the horizontal section of the air outlet pipe for A 0 , the total area of the cross-section perpendicular to the air flow directed to the air inlet is A 1 , the total area of the cross-section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com