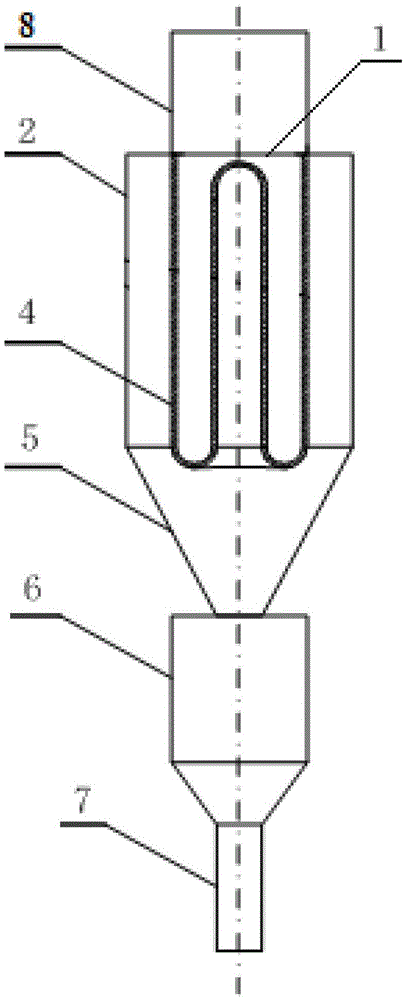

A gas-solid separation device

A gas-solid separation and equipment technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as wear of solid particles, achieve long service life, reduce the number of backflushing, and achieve the effect of good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

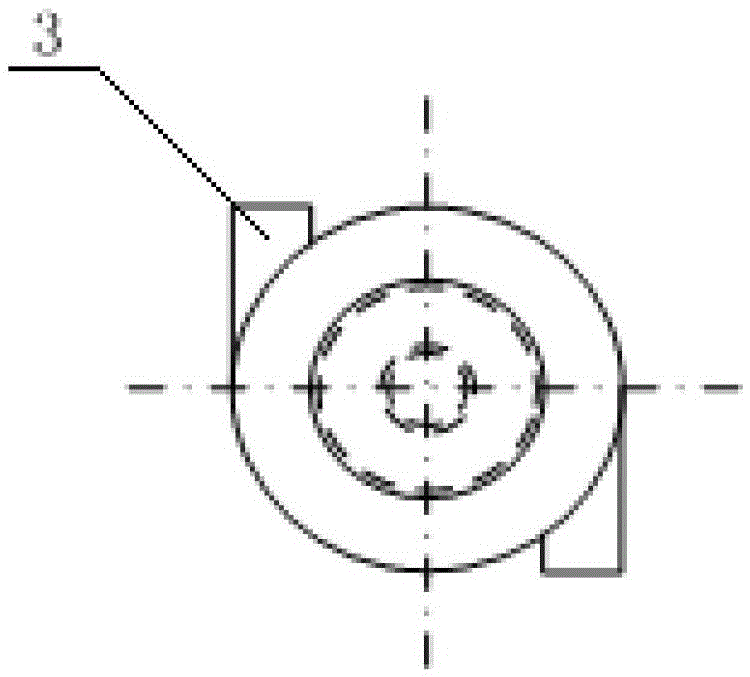

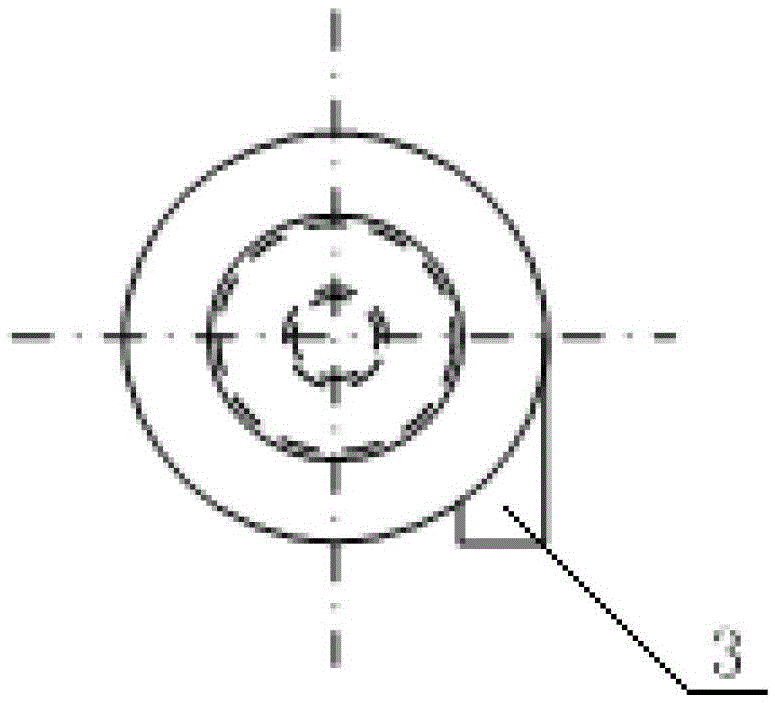

[0061] Adopt the described gas-solid separation equipment of above-mentioned more preferred embodiment to implement gas-solid separation process, wherein, cyclone separator has two feeding ports 3 (such as image 3 shown), the two feed ports 3 are respectively located on both sides of the cylinder 2 close to the top. The gas-solid mixture is a gas-solid mixture of gasoline-adsorbed desulfurization adsorbent solid particles with an average particle size of 65.0 microns and air. The inlet linear velocity of the gas-solid mixture entering the feed port 3 is 3m / s. Collect solid particle by dipleg 7, know by detection and calculation, the recovery rate of solid particle and average particle diameter are as shown in table 1; The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com