A method for extracting tobacco flavor and fragrance from cigarette factory processing waste gas

A technology for tobacco flavors and cigarette factories, which is applied in the field of extracting tobacco flavors and fragrances from the processing waste gas of cigarette factories, and can solve the problems of cumbersome molecular distillation process, waste, and difficulty in obtaining effective distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

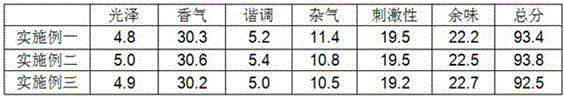

Examples

Embodiment 1

[0017] A cigarette factory extracts tobacco flavors and fragrances from processing waste gas. The specific operation steps are as follows:

[0018] 1. The exhaust gas from the cigarette factory passes through the activated carbon fiber layer 30mm and the adsorbent layer 80mm successively at a flow rate of 0.7m / s. The adsorbent layer is composed of cellulose acetate tow for tobacco and potassium chloride grains; The mass ratio of fiber tow and potassium chloride grain is 8.5:1.

[0019] ② Rinse and wash the activated carbon fiber layer. The washing solution is an aqueous solution of tea polyphenols with a mass concentration of 0.8%. After the activated carbon fiber layer is rinsed, it can be used again. The stirring speed is 300r / min, and it is divided into three layers, the upper layer is tobacco leaf powder, the middle layer is an aqueous solution, and the lower layer is an insoluble organic solution, and the middle layer and the lower layer contain precipitation;

[0020] ③...

Embodiment 2

[0025] A cigarette factory extracts tobacco flavors and fragrances from processing waste gas. The specific operation steps are as follows:

[0026] 1. The exhaust gas from the cigarette factory passes through the activated carbon fiber layer 35mm and the adsorbent layer 90mm successively at a flow rate of 0.8m / s. The adsorbent layer is composed of cellulose acetate tow and potassium chloride grains for cigarettes; The mass ratio of fiber tow and potassium chloride grain is 8.7:1.

[0027] ② Rinse and wash the activated carbon fiber layer. The washing solution is an aqueous solution of tea polyphenols with a mass concentration of 1.0%. After the activated carbon fiber layer is rinsed, it can be used again. The stirring speed is 350r / min, and it is divided into three layers, the upper layer is tobacco leaf powder, the middle layer is an aqueous solution, and the lower layer is an insoluble organic solution, and the middle layer and the lower layer contain precipitation;

[0028...

Embodiment 3

[0033] A cigarette factory extracts tobacco flavors and fragrances from processing waste gas. The specific operation steps are as follows:

[0034] 1. The exhaust gas from the cigarette factory passes through the activated carbon fiber layer 40mm and the adsorbent layer 100mm successively at a flow rate of 0.9m / s. The adsorbent layer is composed of cellulose acetate tow and potassium chloride grains for cigarettes; The mass ratio of fiber tow and potassium chloride grain is 9:1.

[0035] ② Rinse and wash the activated carbon fiber layer. The washing solution is an aqueous solution of tea polyphenols with a mass concentration of 1.2%. After the activated carbon fiber layer is rinsed, it can be used again. The stirring speed is 400r / min, and it is divided into three layers, the upper layer is tobacco leaf powder, the middle layer is an aqueous solution, and the lower layer is an insoluble organic solution, and the middle layer and the lower layer contain precipitation;

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com