LED sine pulse type narrow pulse drive power supply

A technology of driving power supply and narrow pulse, which is applied in the field of integrated circuits, can solve problems such as the decrease of light efficiency, and achieve the effects of constant current, small wave and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

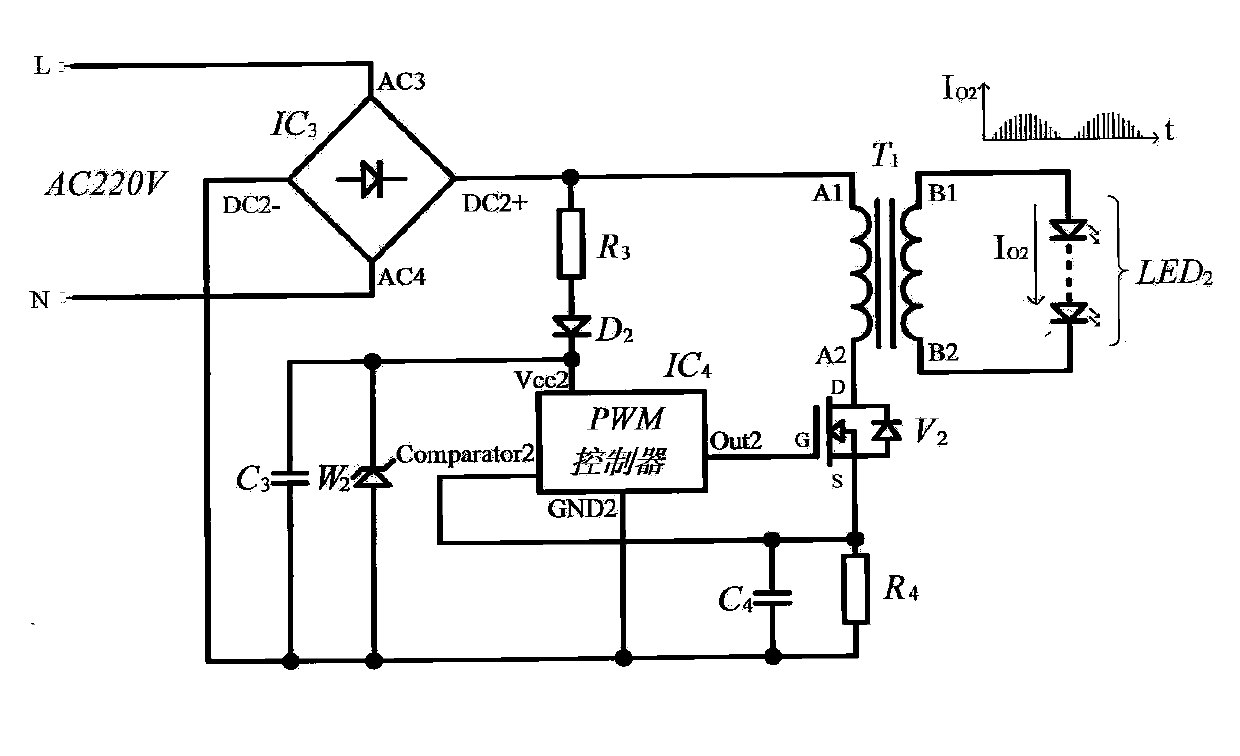

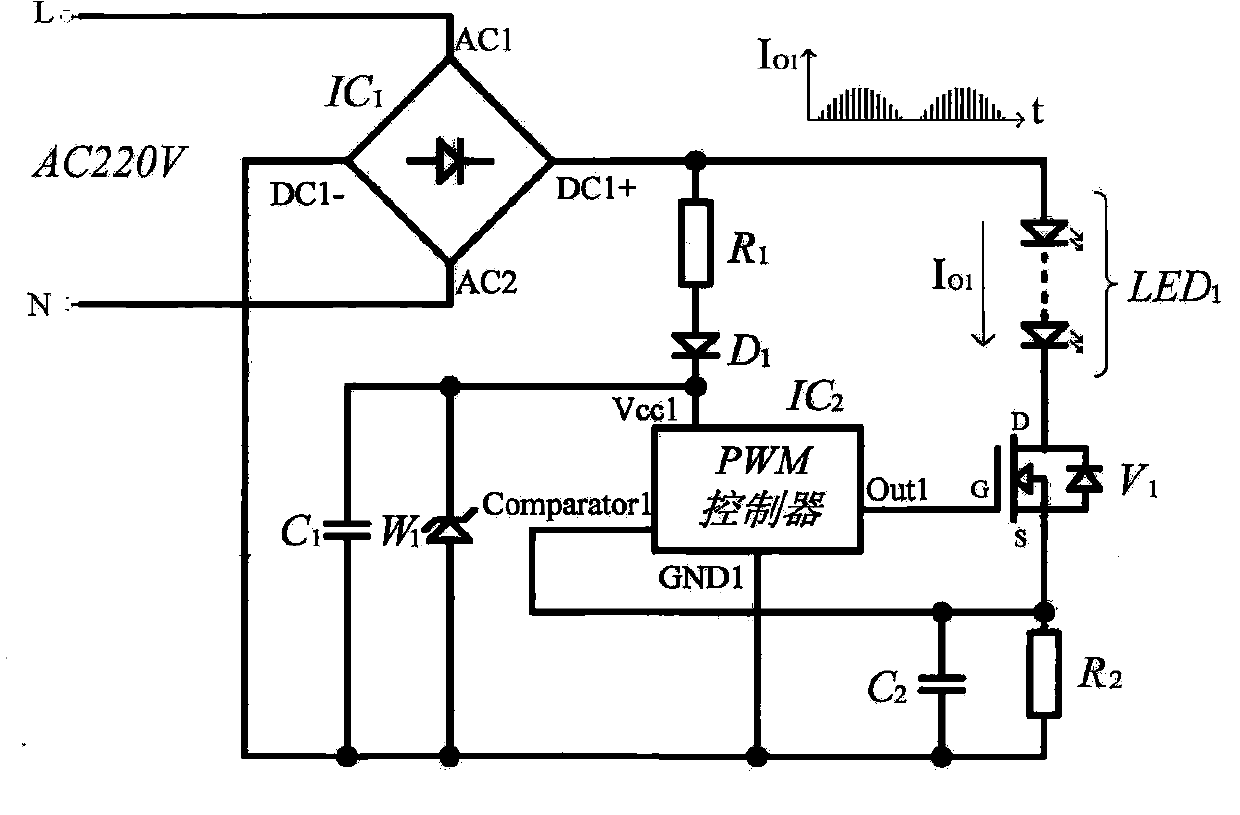

[0011] 1) by figure 1 It can be seen that a kind of LED sinusoidal pulsation type narrow pulse drive power supply of the present invention is characterized in that the L end and the N end of the AC220V alternating current voltage are respectively connected with the rectifier bridge IC 1 The AC1 terminal and AC2 terminal are connected, the rectifier bridge IC 1 The DC1+ terminal and the resistor R 1 one end, and the light-emitting diode led 1 Anode phase connection, bridge rectifier IC 1 The DC1-terminal and the capacitor C 1 One end of the regulator tube W 1 anode, PWM controller IC 2 GND1 terminal, capacitor C 2 One end and the resistor R 2 connected at one end, the resistor R 1 the other end of the diode with the D 1 The anode of the diode is connected to the D 1 cathode with PWM controller IC 2 Vcc1 terminal, capacitance C 1 The other end of the regulator tube W 1 The cathode of the PWM controller is connected to the IC 2 Out1 terminal and pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com