An electric vehicle power battery waste heat utilization device

A technology for power batteries and electric vehicles, applied in electric vehicles, battery circuit devices, circuit devices, etc., can solve problems such as difficulty in meeting heat dissipation requirements, low heat transfer coefficient, energy waste, etc., and achieve simple structure, perfect heat dissipation system, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

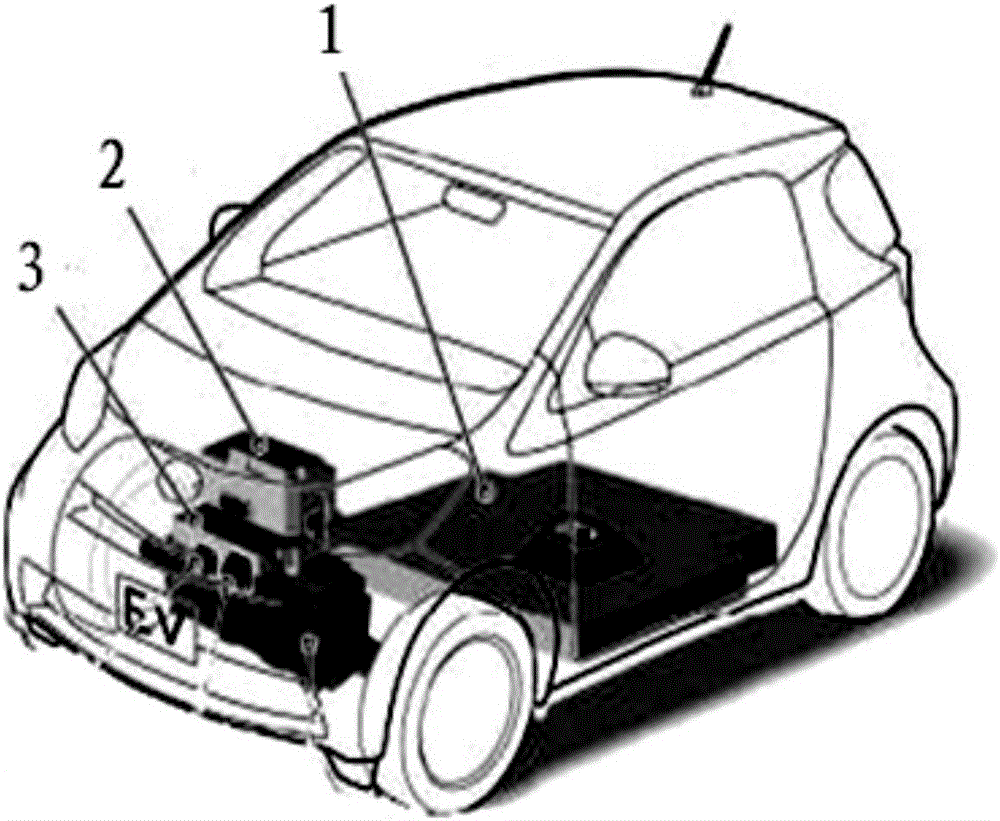

[0023] Such as figure 1 Shown is a schematic diagram of the installation of an electric vehicle power battery waste heat utilization device in an electric vehicle. The electric energy generated by the thermoelectric power generation circuit 1 is amplified and stabilized by the voltage stabilizing circuit 2 to be used by the electrical equipment 3 .

[0024] Among them, the electric vehicle power battery waste heat utilization device includes a power battery pack 4, a thermoelectric power generation circuit 1 and a voltage stabilizing circuit 2, and the structure of each part will be described in detail below.

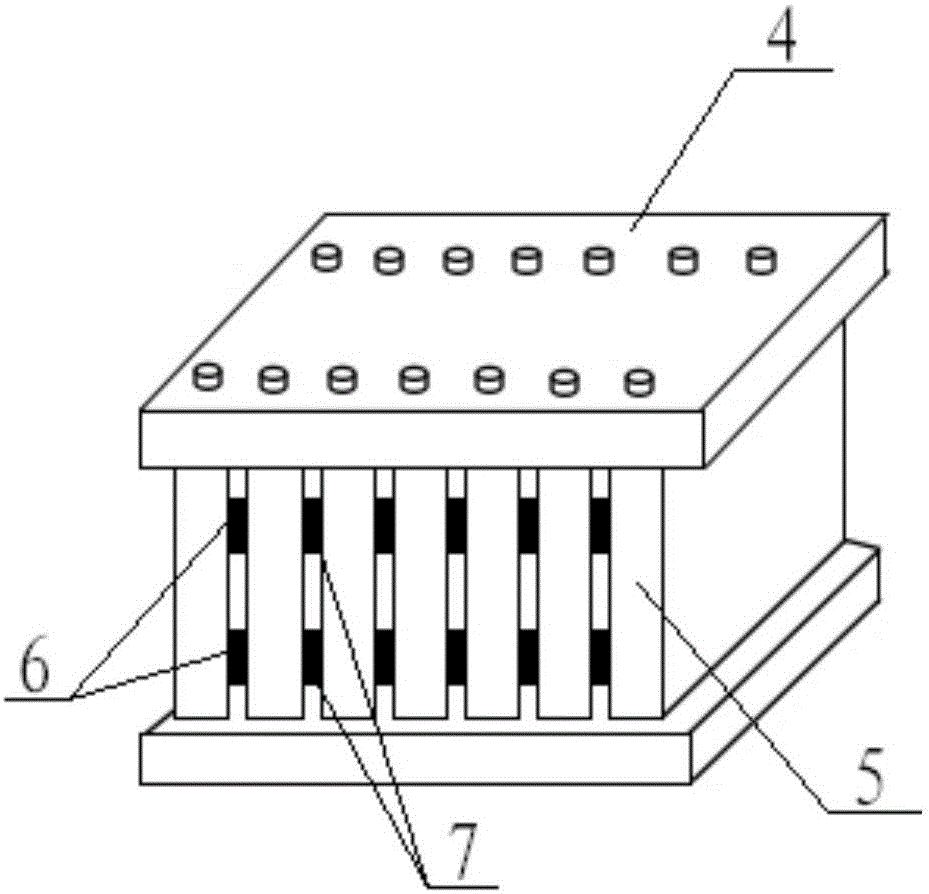

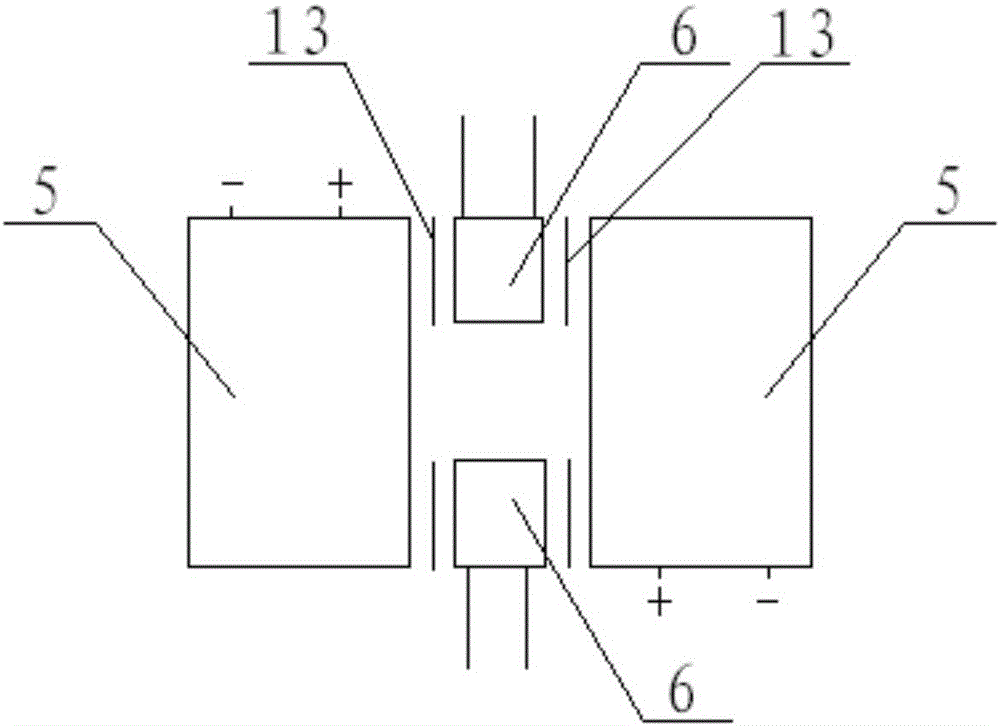

[0025] Such as Figure 2 to Figure 5 As shown, the power battery pack 4 is composed of more than two battery cells 5 arranged in series along the width direction; note that the side of the battery cell 5 with the electrode joint is the top surface, which is opp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com