Hopkinson pressure rod electromagnetic buffer energy absorbing device

A technology of Hopkinson pressure rod and energy-absorbing device, which is applied in the direction of magnetic spring, spring, spring/shock absorber, etc., which can solve the problems of poor operability and economy, inability to dissipate energy in time, and damage to the absorbing rod device. Achieve the effects of improving intelligence and safety, adjusting the strength of the magnetic field, and efficiently dissipating energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

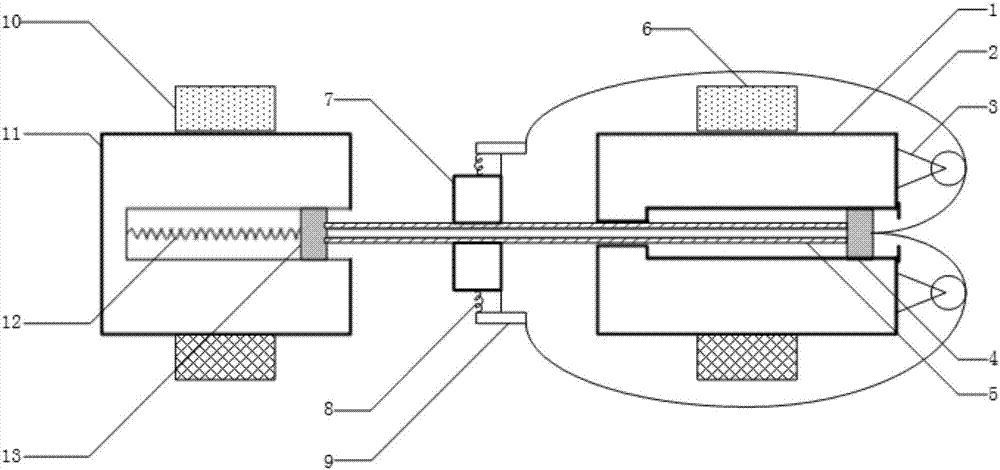

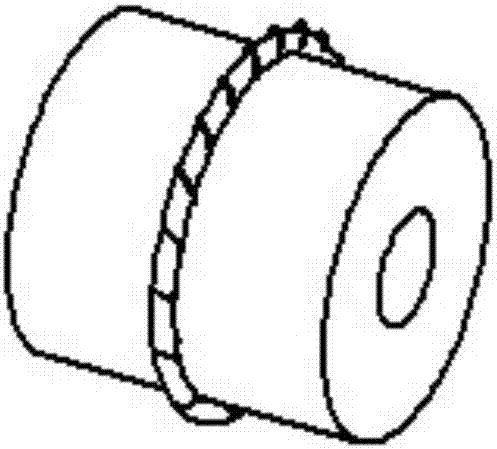

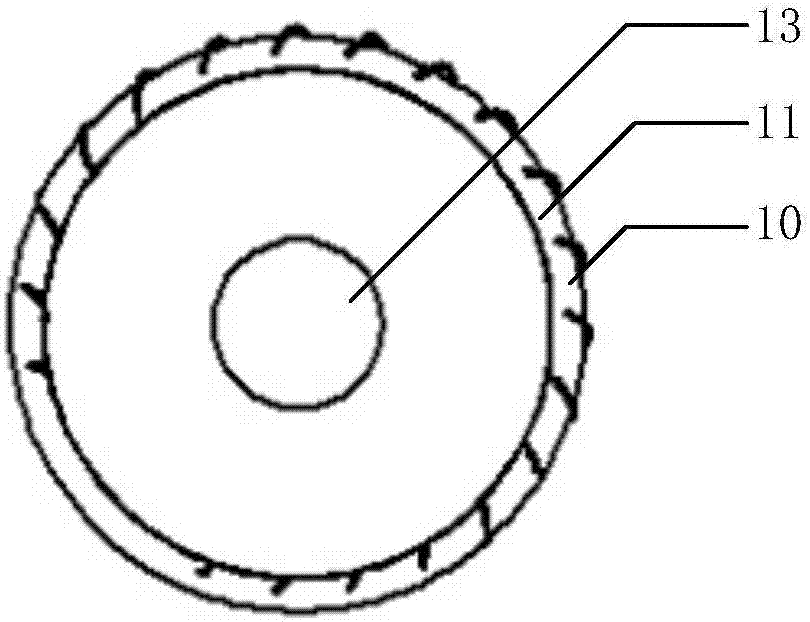

[0014] Combine Figure 1 to Figure 4 , The present invention includes: No. 1 metal base 1, two ropes 2, two fixed pulleys 3, No. 1 iron block 4, metal connecting rod 5, ring electromagnet 6 constitute the first layer of shock energy absorption system; ring brake 7. No. 2 spring 8, two sets of levers 9 form the second layer of impact energy absorption system; No. 2 metal base 10, ring electromagnet 11, No. 1 spring 12, and No. 2 iron block 13 form the third layer of impact energy absorption system system. The ring brake 7 can be formed by splicing two upper and lower semi-circular brakes.

[0015] In the first-layer shock-absorbing energy-absorbing device and the third-layer shock-absorbing energy-absorbing device, the external power supply is used to directly supply power to the ring electromagnet 6 and the ring electromagnet 10, and the magnetic fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com