Graphene/graphene oxide thin film and preparation method thereof, and super capacitor

A graphene film and graphene technology, which is applied in the field of electrochemistry, can solve the problems of reducing the safety of batteries or supercapacitors, low energy density of batteries or supercapacitors, and increasing electrode reaction resistance, and achieves the electrochemical stable potential window. Large, excellent mechanical properties and electrical conductivity, the effect of enhancing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

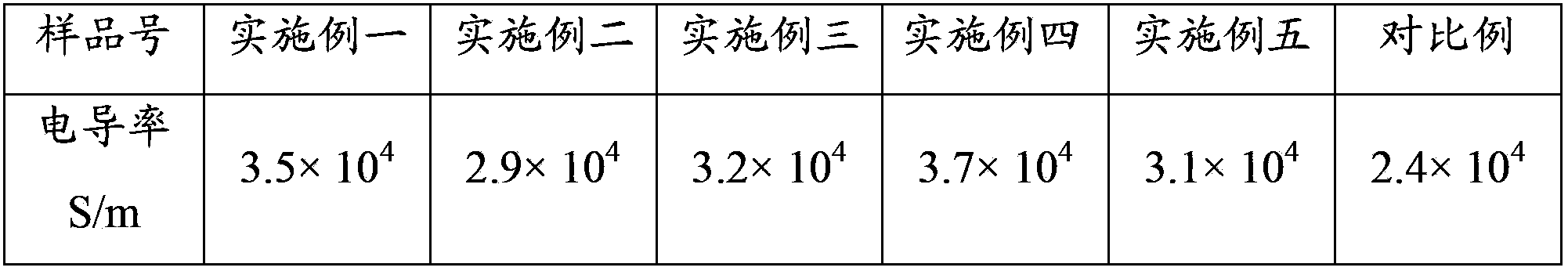

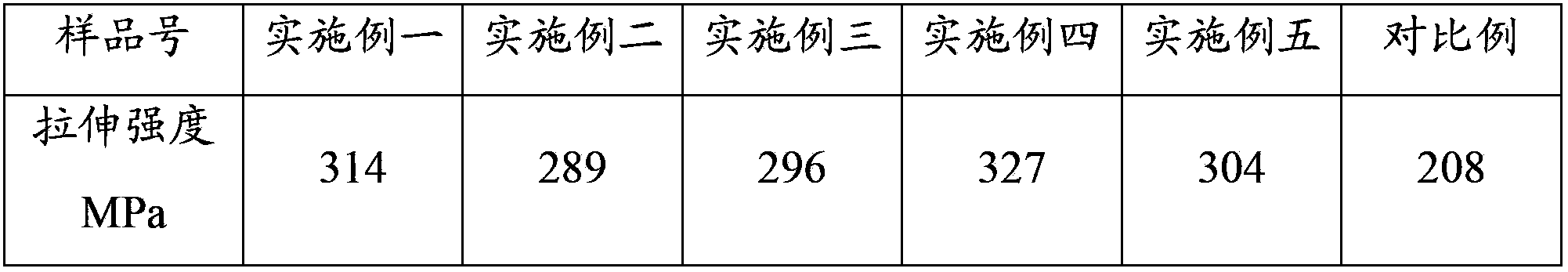

Examples

Embodiment 1

[0042] A kind of preparation method of graphene / graphene oxide thin film, comprises the following steps:

[0043] (1) Preparation of graphene oxide film: Take 0.14g of graphite oxide and disperse it in 560mL of deionized water, and ultrasonically prepare a suspension of graphene oxide with a concentration of 0.25g / L, which is vacuum filtered through a microporous filter membrane to obtain a filter. Cake, weigh copper nitrate according to the mass ratio of copper element to graphene oxide 0.01:1, add water to make a 50% concentration of copper nitrate solution, soak the filter cake in the copper nitrate solution, soak for 10min, filter the microporous membrane Peel it off, rinse the filter cake twice with ethanol, and dry it in a vacuum oven at 40°C to obtain a graphene oxide film with a thickness of 3 μm.

[0044] (2) Preparation of graphene suspension: add 1g of 1-hexadecyl-3-methylimidazolium bromide to 2L of water to prepare 1-hexadecyl-3-methylimidazolium with a concentrat...

Embodiment 2

[0047] A kind of preparation method of graphene / graphene oxide thin film, comprises the following steps:

[0048](1) Preparation of graphene oxide film: Take 0.37g of graphite oxide and disperse it in 750mL of ethanol, and ultrasonically prepare a suspension of graphene oxide with a concentration of 0.5g / L, which is vacuum filtered through a microporous membrane to obtain a filter cake , according to the mass ratio of cobalt element and graphene oxide 0.05:1, take cobalt nitrate, add water and make concentration be 40% cobalt nitrate solution, soak this filter cake in the solution of cobalt nitrate, soak 30min, microporous filter The film was peeled off, the filter cake was rinsed with ethanol three times, and dried in a vacuum oven at 50°C to obtain a graphene oxide film with a thickness of 8 μm.

[0049] (2) Preparation of graphene suspension: add 0.5g of 1-butyl-3-methylimidazolium hexafluorophosphate to 1L of DMF to prepare 1-butyl-3-methyl with a concentration of 0.5g / L ...

Embodiment 3

[0052] A kind of preparation method of graphene / graphene oxide thin film, comprises the following steps:

[0053] (1) Preparation of graphene oxide film: Take 0.47g of graphite oxide and disperse it in 630mL of isopropanol, ultrasonically prepare a suspension of graphene oxide with a concentration of 0.75g / L, and vacuum filter it through a microporous membrane to obtain Filter cake, take nickel nitrate according to the mass ratio of nickel element and graphene oxide 0.1:1, add in water and be made into the nickel nitrate solution that concentration is 30%, this filter cake is soaked in nickel nitrate solution, soaks 60min, micro The porous filter membrane was peeled off, the filter cake was washed 4 times with ethanol, and dried in a vacuum oven at 60°C to obtain a graphene oxide film with a thickness of 10 μm.

[0054] (2) Preparation of graphene suspension: Add 0.3g of 1-ethyl-3-methylimidazole hexafluorophosphate to 300mL DMSO to prepare 1-ethyl-3-methylimidazole with a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com