Oxide tape-casting slurry-based oxygen sensor for vehicle and manufacture method of sensor

A technology of a vehicle oxygen sensor and a manufacturing method, applied in the field of sensors, can solve the problems of human health hazards, easily polluting the environment, affecting the sensitivity of sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

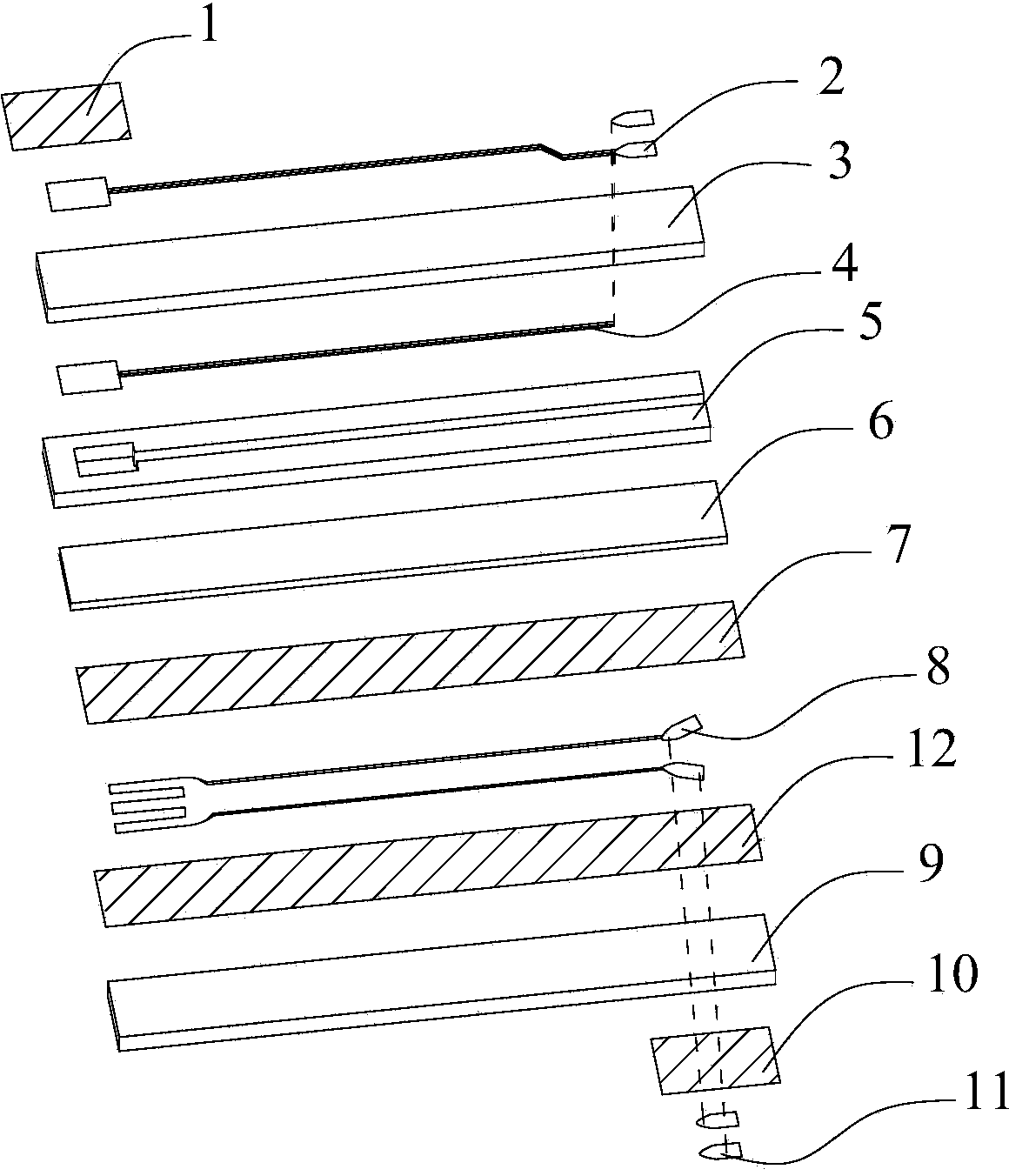

Image

Examples

Embodiment 1

[0032] In this embodiment, the casting slurry includes the following materials in parts by weight: 6 parts of zirconia powder, 4 parts of organic solvent, 1 part of auxiliary agent, and the particle size of zirconia powder is <1um, wherein,

[0033] The organic solvent includes the following parts by weight: 7 parts of pure hexyl acetate and / or propyl acetate for analysis, 3 parts of pure ethanol and / or isobutanol for analysis, and the organic solvent in the present invention adopts nontoxic hexyl acetate And / or propyl acetate and ethanol and / or isobutanol, it has avoided the pollution to environment and the harm to human health compared with the mode that adopts toxic solvents such as butanone, xylene in the prior art;

[0034] The auxiliary agent includes the following substances by weight: 1 part of dispersant, 7 parts of binder and 1 part of plasticizer.

[0035] Among them, the casting aid uses PVB imported from the United States as a binder, and its glass transition temp...

Embodiment 2

[0037] In this embodiment, the insulating paste includes the following substances by weight: 5 parts of inorganic powder, 3 parts of organic vehicle, and 2 parts of additives, wherein,

[0038] The inorganic powder includes the following materials in parts by weight: 20 parts of alumina, 1 part of zirconia, wherein the alumina is a mixture of 6 parts of α-phase low-temperature sintered alumina and 14 parts of γ-phase alumina with a particle size of <15nm;

[0039] The organic carrier is a mixed solution after water bath treatment, and the organic carrier includes the following substances in parts by weight: 25 parts of terpineol, 1 part of ethyl cellulose;

[0040] The auxiliary agent includes the following substances by weight: 6 parts of dispersant, 3 parts of binder, 3 parts of leveling agent and 1 part of thixotropic agent.

Embodiment 3

[0042] In this embodiment, the protective slurry includes the following parts by weight: 4 parts of oxide, 2 parts of pore-forming agent, 2 parts of organic vehicle, and 1 part of auxiliary agent, wherein,

[0043] The oxides include one or more of the following materials in parts by weight: 20 parts of aluminum oxide, 1 part of zirconia, 1 part of magnesium oxide, and 1 part of silicon oxide;

[0044] The pore-forming agent is nano-carbon powder with a particle size range of 0.1um-1um;

[0045] The organic carrier includes the following materials in parts by weight: 58 parts of terpineol, 25 parts of ethyl cellulose, and 2 parts of ethanol;

[0046] The auxiliary agent includes the following substances by weight: 6 parts of binder, 3 parts of dispersant, 3 parts of plasticizer, and 1 part of leveling agent.

[0047] About the manufacture method of this vehicle oxygen sensor, the present invention proposes following embodiment:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com