Control oil line of variable valve timing system

A valve timing and oil circuit control technology, which is applied to non-mechanically actuated valves, engine components, machines/engines, etc. Crossover is not independent and other problems, to achieve the effect of short control oil circuit layout, reduce oil pumping capacity, and shorten oil pumping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

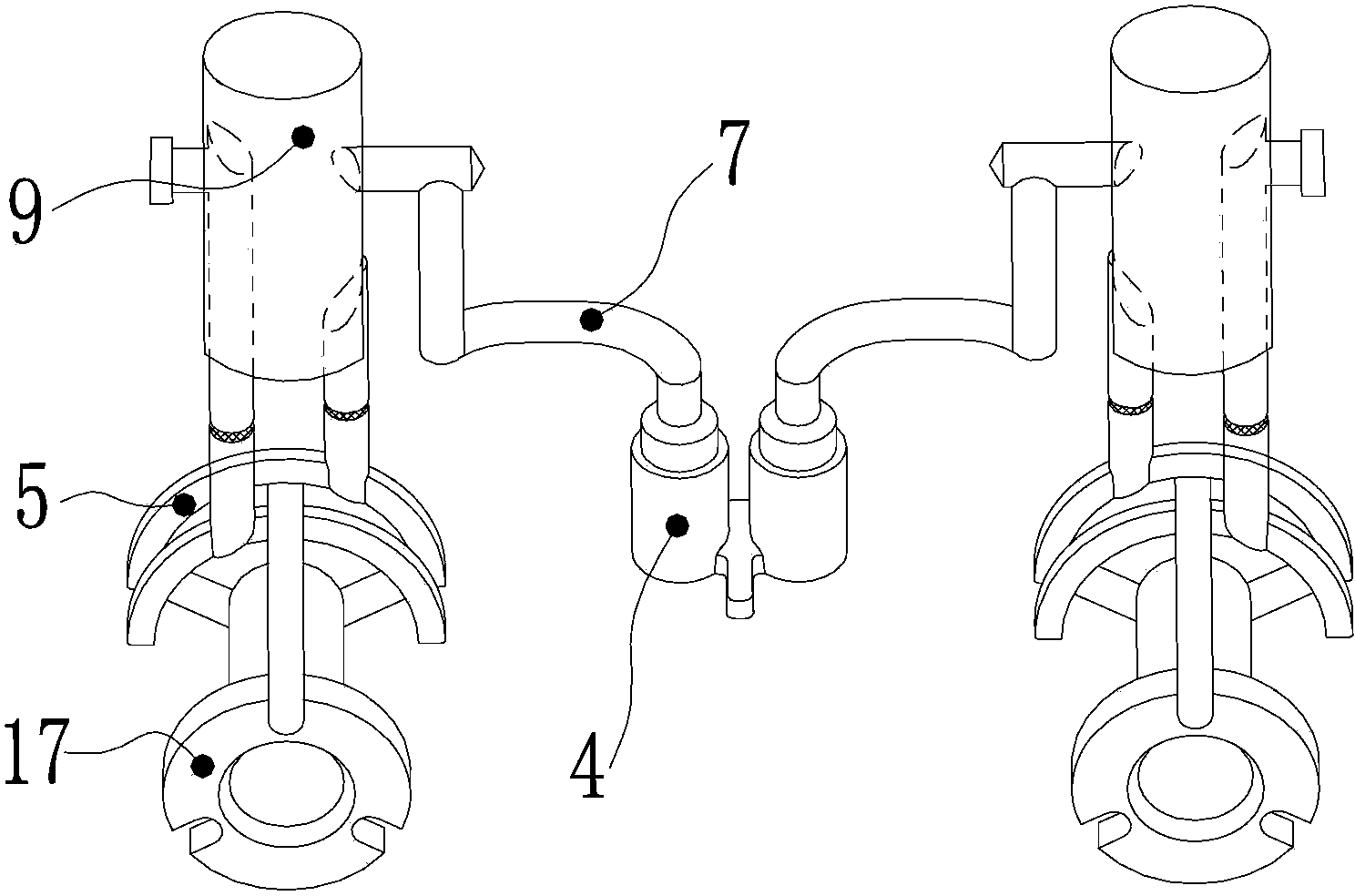

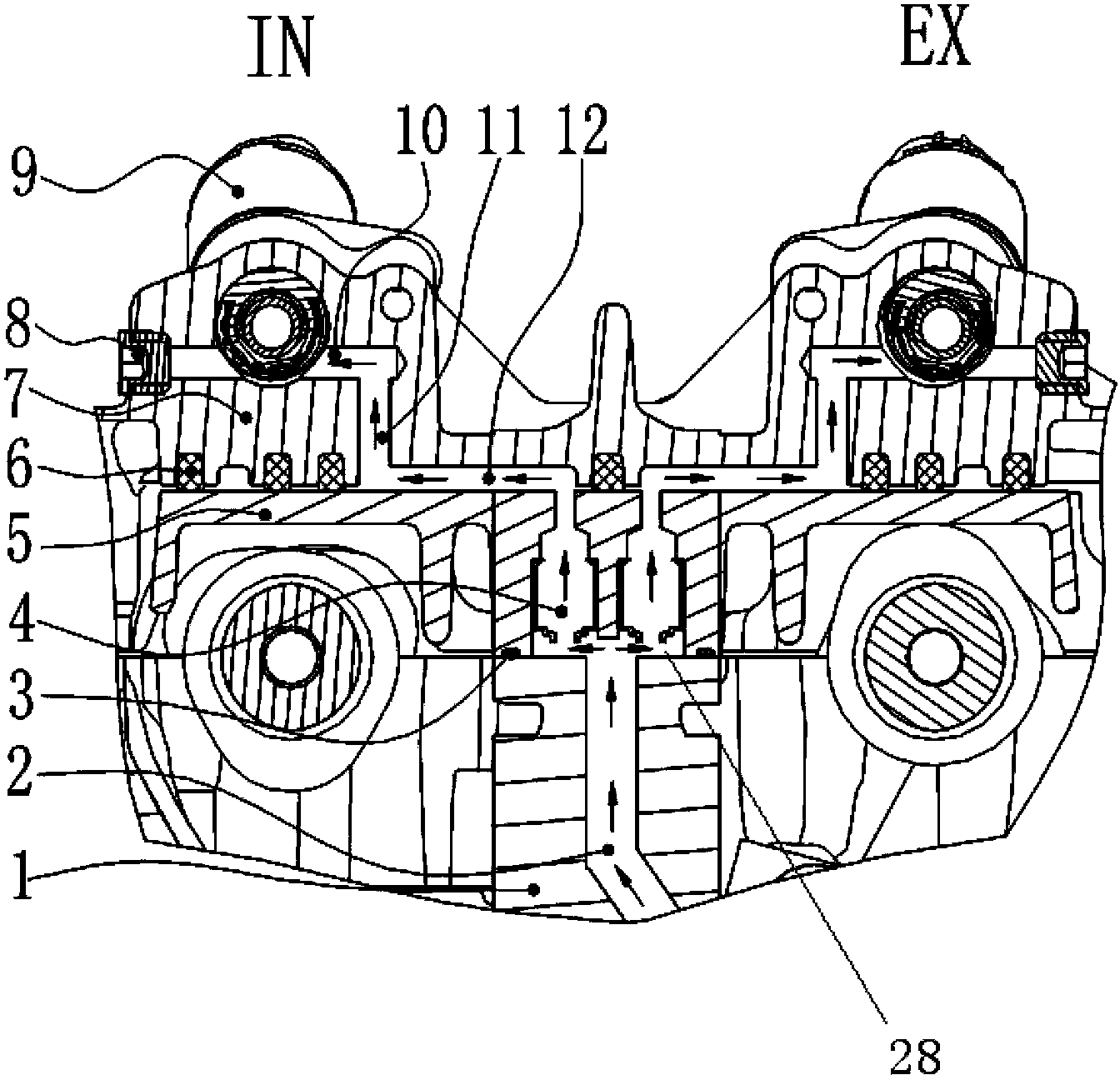

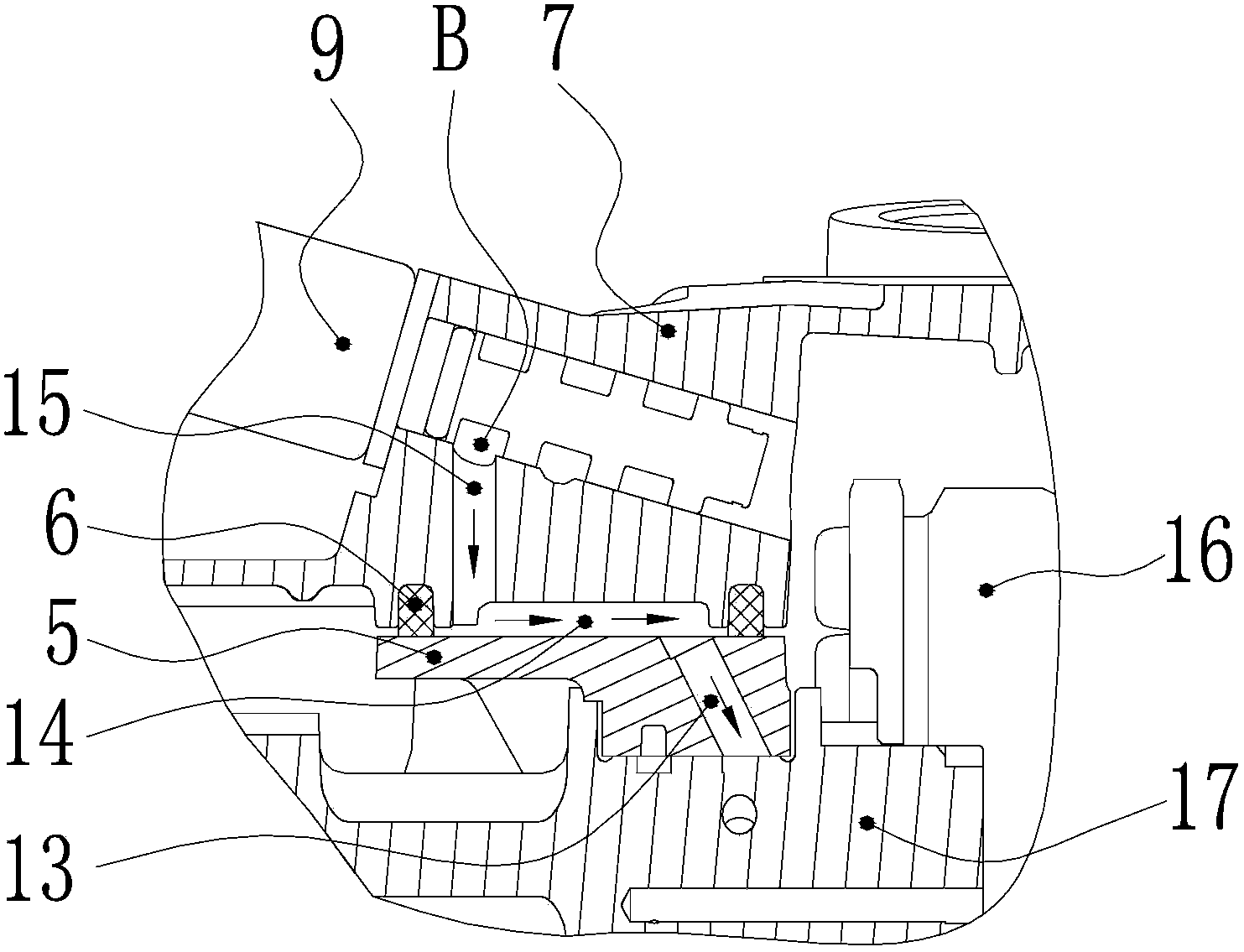

[0020] The present invention will be further explained below in conjunction with the drawings:

[0021] See Figure 1 to Figure 5 As shown, the control oil circuit of the variable valve timing system includes the intake and exhaust valve variable timing oil circuits. The inlet and exhaust valve variable timing oil circuits are respectively arranged in the cylinder head 1. The outlet of the main oil passage 2 is connected. The variable timing oil passages of the intake and exhaust valves and the exhaust valve variable timing oil passages have the same structure, which are symmetrically distributed on the camshaft bearing cover 5, camshaft 17 and cylinder head cover 7 ; From the front of the engine, the left side is the variable timing oil circuit of the intake valve, and the right side corresponds to the variable timing oil circuit of the exhaust valve.

[0022] The variable timing oil circuit of the intake valve includes a mounting hole for the oil control valve 9 arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com