Self-cooled thermal power acting method

A self-cooling, work-based technology, applied in heat pumps, refrigerators, refrigeration components, etc., can solve problems such as unimpeded exploration and thinking, large flow loss, energy waste, etc., to solve the problem of volume loss, high efficiency and low cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0050] Embodiment 1, closed self-cooling thermodynamic cycle:

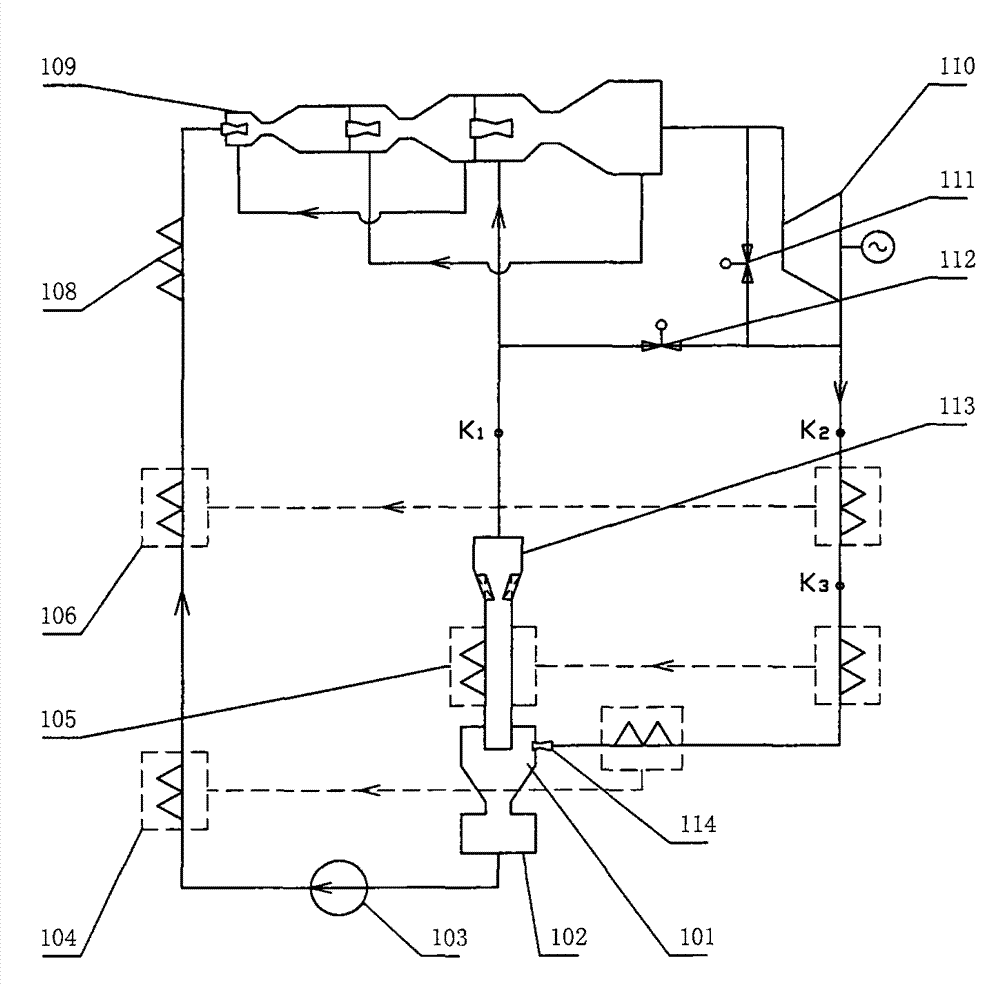

[0051] as attached figure 1 The closed self-cooling thermodynamic cycle shown uses the jet refrigeration liquefaction system 101 to realize the heat removal and liquefaction of the gas working medium, and uses the circulation jet extractor 109 and the gas turbine unit 110 (or other types of expanders) to form an expansion work system at the same time Provide pumping and injection power for the refrigeration liquefaction system, the working medium can generally be air, nitrogen, CO, whose boiling point is lower than normal temperature 2 Or a gas such as freon, or a high boiling point gas such as water vapor. Along the flow direction of the working medium indicated by the arrow, the liquid working medium produced by the refrigeration liquefaction system 101 is boosted by the pump 103, then passes through the recuperation heat exchangers 104, 105 and 106 to absorb heat, and then passes through the heater 108 to abso...

Embodiment approach 2

[0066] Embodiment 2, new jet extractor:

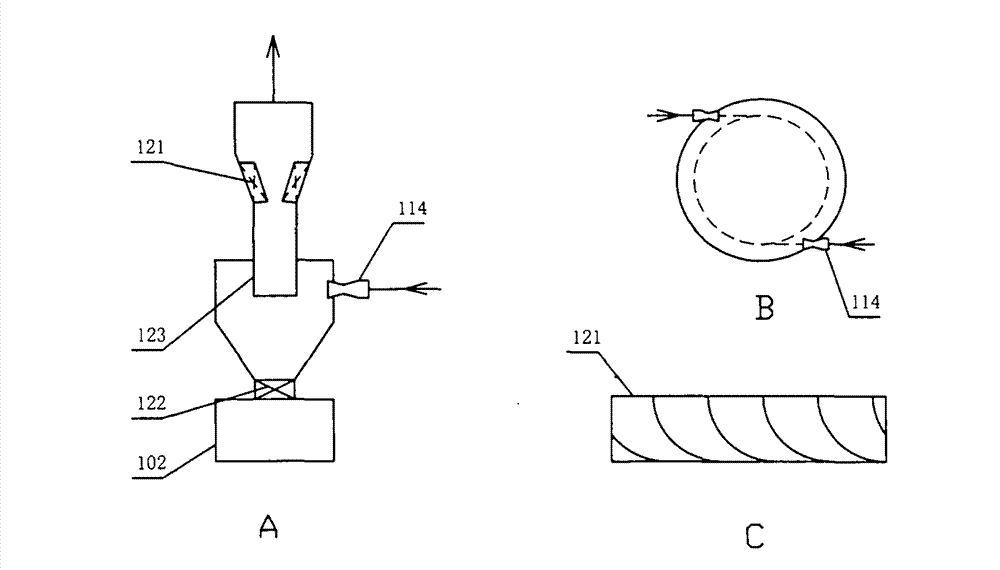

[0067] with attached figure 1 , attached Figure 5 and attached Image 6 The multi-stage cycle jet extractor used in the paper is different, as attached Figure 7Shown is a straight-through pipe swirl jet extractor. The injection and diffusion process abandons the traditional throat zoom structure and adopts a straight-through pipe (not limited to straight pipes with equal diameters, which can be gradually expanded or tapered) swirl injection. Among them, A is a schematic diagram of single-stage injection structure, B is a schematic diagram of porous injection, C and D are schematic diagrams of oblique swirling jets, and there is a flow guide device at the end, and E is a straight-through pipe swirling multi-stage circulating jet air extractor.

[0068] attached Figure 8A It is a split-type multi-stage serial circulation jet extraction system that adopts the combination of reheating method and gas turbine; Figure 8B The split ar...

Embodiment approach 3

[0071] Embodiment 3, self-cooling thermodynamic cycle using compression and cooling liquefaction:

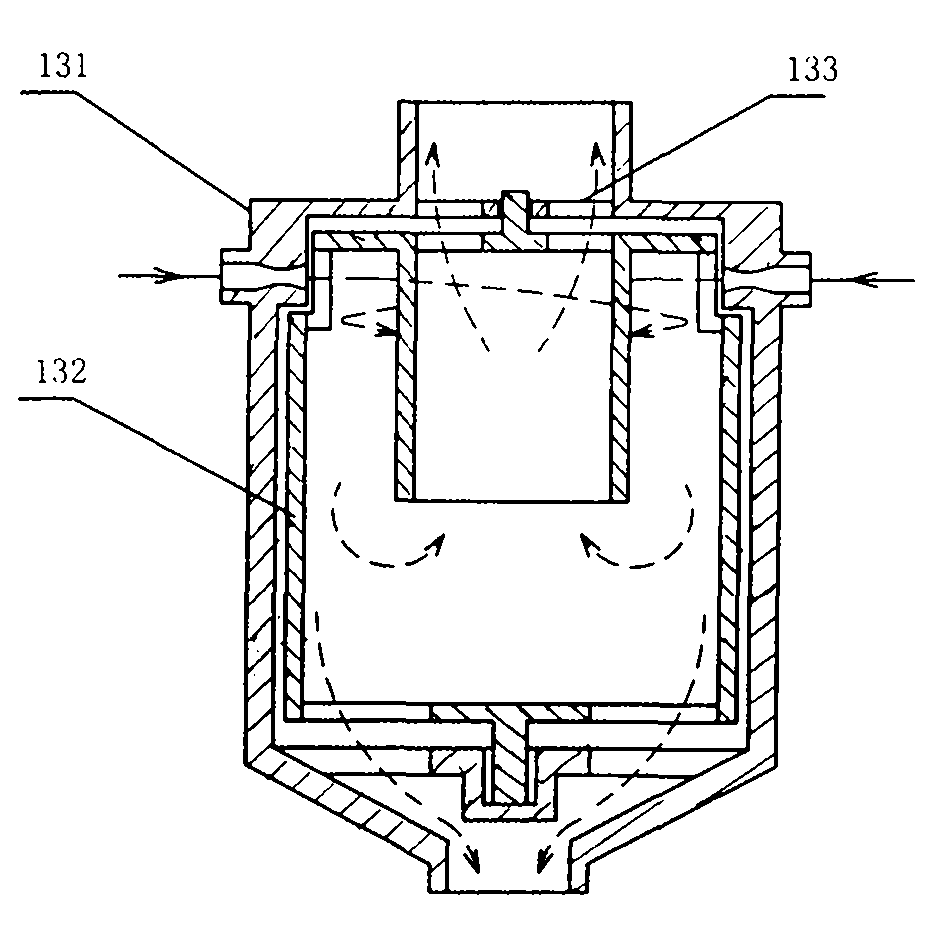

[0072] attached Figure 15 It is the two jet swirl heat exchange methods of the jet swirl heat exchange heat pump. The working medium absorbs heat from the low temperature environment or the low temperature working medium through expansion. Spray tangentially or obliquely into the cyclone through the nozzle, the spray process and the attached figure 2 The spray swirl shown is similar. After the high-speed jet cools down, it absorbs heat through the wall of the swirler and the external working fluid or environment, and then enters the exhaust pipe to be discharged. The exhaust pipe adopts a straight-through method or a deflector that increases the recovery swirl power. Way. Among them, the built-in exhaust pipeline of A can reduce the volume, and the exhaust pipeline of B can be designed with a large diameter to reduce resistance. The heat exchange process can be composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com