Ninety-degree all-dimensional hydraulic drill carriage for coal-mine gas control end-located drainage roadway

A hydraulic drilling rig and coal mine gas technology, which is applied in earthwork drilling, drilling equipment, drilling equipment and methods, etc., can solve the problems of insufficient stability of the drilling rig, limited rotation angle, large width of the deep hole drilling rig, etc., and achieve Better operating effect, increased lifting formation, and convenient mobile operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

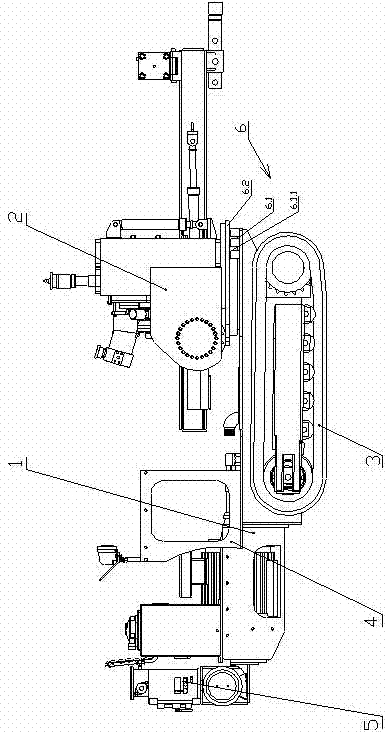

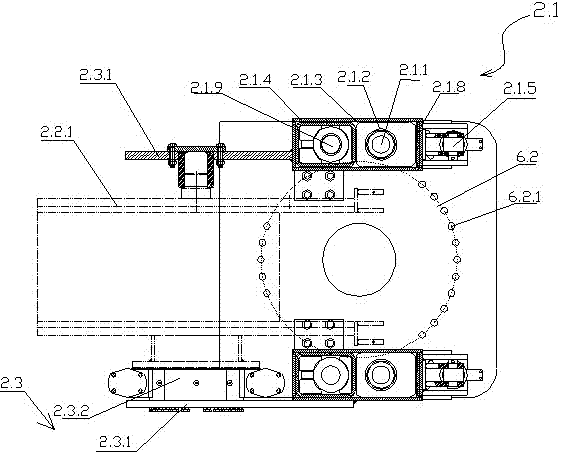

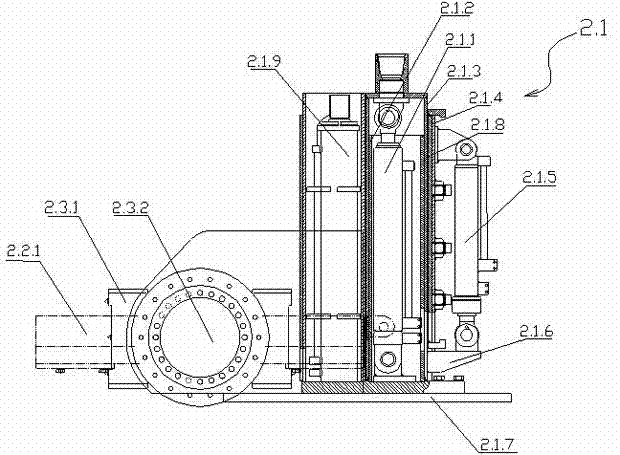

[0033] see Figure 1~4 The present invention relates to a 90-degree all-round hydraulic drilling rig for coal mine gas control bottom pumping roadway. The slewing platform 6, the crawler belt running part 3 is located at the bottom of the main machine body 1 to provide walking power, the working mechanism 2 is installed on the main machine body 1 through the slewing platform 6, as the main body of the operation, the hydraulic device 4, the electric control box 5 And supporting devices such as the cab are all installed on the main engine body 1 to provide power or control for the working mechanism 2; the rotary platform 6 can be driven manually, electrically or hydraulically. Preferably, in this embodiment, the rotary platform 6 includes a lower chassis 6.1 fixed on the host machine body 1, and an upper tray 6.2 installed on the lower chassis 6.1 through a slewing bearing, and the lower chassis 6.1 is provided with a plurality of positioning cylinders 6.1.1, and the upper tray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com