Filter paper for environmental-friendly automobile filter and preparation method of filter paper

A filter and filter paper technology, applied in chemical instruments and methods, filter paper, separation methods, etc., to achieve the effects of improved dynamic performance, obvious comprehensive effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Preparation of far-infrared ceramic powder:

[0039] 0.8kg of magnesium tourmaline ultrafine powder with a median diameter of 0.45μm, and La with a median diameter of 0.36μm 2 o 3 0.1kg, Fe 2 o 3 0.2kg, MnO 2 0.3kg, Co 2 o 3 0.2kg, CuO0.2kg.

[0040] 2. Preparation of filter paper:

[0041] 1) Add the silane coupling agent and diluent to the far-infrared ceramic powder and stir for 20 minutes, let it stand for 8 minutes, and dry at 100°C; improve the surface properties of the ceramic powder, make it better integrated with the pulp, and increase the powder in the paper of firmness.

[0042] 2) Add the far-infrared ceramic powder, sepiolite nanofibers, and sizing agent after surface pretreatment in step 1) to the beaten wood pulp at the same time, use mechanical stirring to make it evenly mixed, and then add water to adjust the concentration to 3.2% , to prepare a slurry;

[0043] 3) Slurry forming, pressing, drying to 92% dryness, calendering and finishing t...

Embodiment 2

[0053] 1. Preparation of far-infrared ceramic powder:

[0054] 2 kg of ferrite ultrafine powder with a median diameter of 1.4 μm, and CeO with a median diameter of 0.08 μm 2 0.2kg, Fe 2 o 3 0.4kg, MnO 2 0.2kg,Co 2 o 3 0.8kg, CuO0.1kg.

[0055] 2. Preparation of filter paper:

[0056] Filter paper was prepared according to the method of Example 1. Among them, high-aspect-ratio sepiolite nanofibers were prepared by high-speed airflow technology, with a diameter of 96 nm and a length of 0.21 μm.

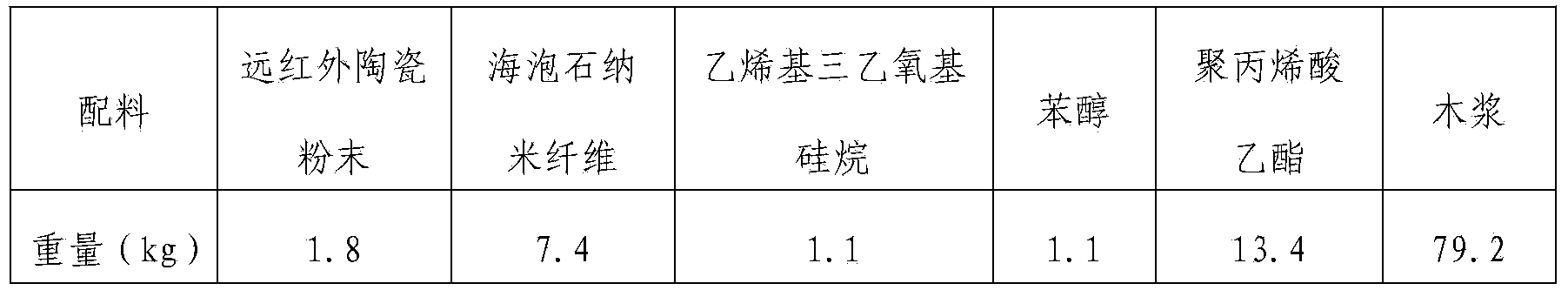

[0057] Among them, the distribution ratio of each group is shown in Table 3.

[0058] The proportioning of table 3 embodiment 2

[0059]

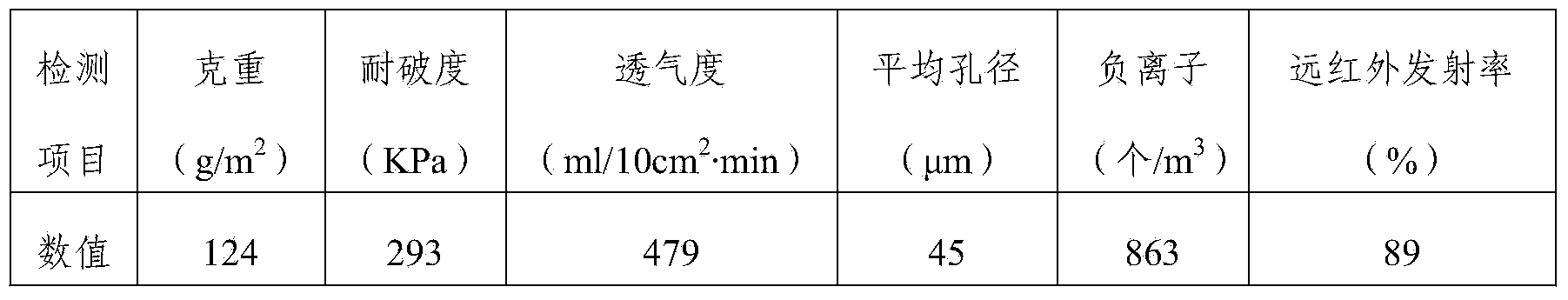

[0060] The results of paper performance testing are shown in Table 4.

[0061] The filter paper performance measurement result of table 4 embodiment 2

[0062]

[0063] The diesel filter made of this filter paper has been tested in practice, and the exhaust pollutants are reduced by 34%, and the emission reaches the Euro IV standard....

Embodiment 3

[0065] 1. Preparation of far-infrared ceramic powder:

[0066] 3.1kg of ultra-fine tourmaline powder with a median diameter of 1.1μm, Ce with a median diameter of 1.7μm 2 o 3 0.2kg, Fe 2 o 3 0.7kg, MnO 2 0.4kg, Co 2 o 3 0.2kg, CuO1.2kg.

[0067] 2. Preparation of filter paper:

[0068] Filter paper was prepared according to the method of Example 1. Among them, high-aspect-ratio sepiolite nanofibers were prepared by high-speed airflow technology, with a diameter of 92 nm and a length of 0.22 μm.

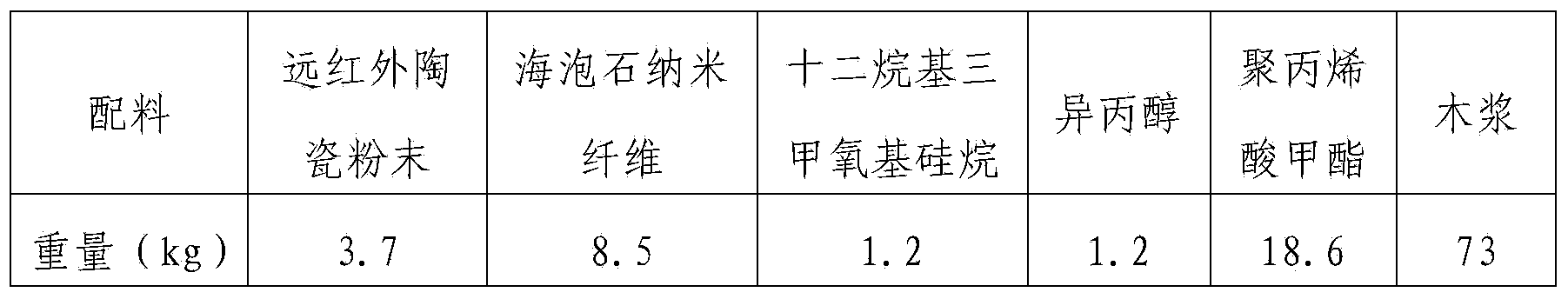

[0069] Among them, the distribution ratio of each group is shown in Table 5.

[0070] The proportioning of table 5 embodiment 3

[0071]

[0072] The results of paper performance testing are shown in Table 6.

[0073] The filter paper property measurement result that table 6 embodiment 3 coating materials prepare

[0074]

[0075] The gasoline filter made of this filter paper has been tested in practice, and the exhaust pollutants are reduced by 27%, and the emission...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com