Method of manufacturing powdered coal for low absorbent fuel using coffee waste

A technology for coffee grounds and fuel, which is applied in the field of preparing pulverized coal for low-absorptive fuel using coffee grounds, can solve the problems of high energy input cost, reduced total energy, difficult to store, etc. The effect of reducing the cost of crushing and improving the storability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the method for preparing pulverized coal for fuel using coffee grounds of the present invention will be described in detail with reference to examples.

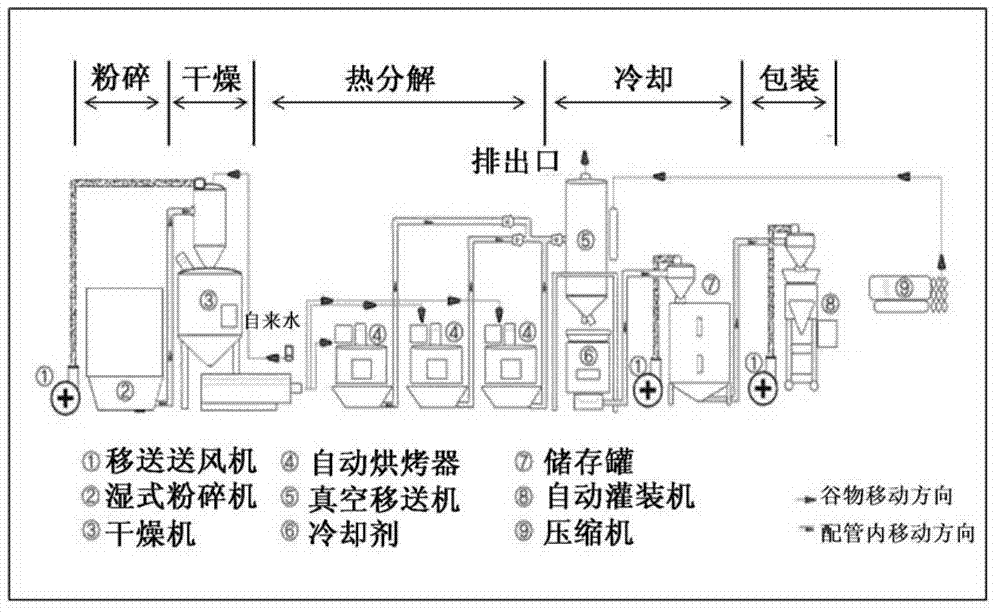

[0021] attached figure 1 It is a preparation process diagram for explaining the preparation method of the pulverized coal for fuel using coffee grounds of this invention.

[0022] As shown in the figure, the method for preparing pulverized coal for fuel using coffee grounds of the present invention includes: firstly crushing the collected coffee grounds; drying the pulverized coffee grounds; The step of thermally decomposing the dried coffee grounds in the stirred roaster; the cooling step of cooling the thermally decomposed coffee grounds; the packaging step of packaging the prepared fuel with pulverized coal.

[0023] Hereinafter, the method for producing pulverized coal for fuel using the above-mentioned coffee grounds of the present invention will be described in more detail as follows.

[0024] Firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com