Diatomite forming composition with moisture absorption function and preparing method thereof

A technology of diatomite and composition, which is applied in the preparation and application field of diatomite-based composite materials, can solve problems such as unfavorable surface cleaning, limitations of raw material formula and manufacturing process, and affect the effect of application, so as to reduce shedding Phenomenon, good water absorption performance, and the effect of improving the moisture absorption function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

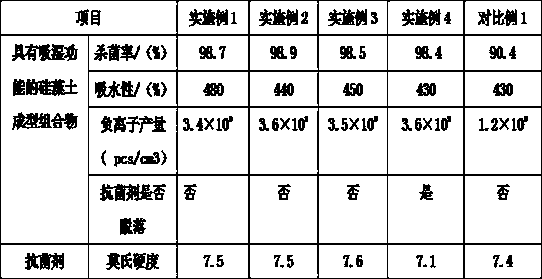

Examples

Embodiment 1

[0024] Embodiment 1: Preparation of diatomite molding composition

[0025] The formula is: a diatomite molding composition with moisture absorption function, the weight percentage of each component of the diatomite molding composition is composed of: diatomite 15%, tourmaline powder 10%, zeolite powder 5%, bamboo charcoal 3%, antibacterial agent 3%, acrylic resin adhesive 0.1%, and the balance is gypsum powder. The antibacterial agent is an inorganic antibacterial agent obtained by attaching silver ions to glass. The particle size of diatomite is 20 μm, and the particle size of tourmaline powder The particle size of gypsum powder is 20 μm, the particle size of bamboo charcoal is 20 μm, the preparation method of antibacterial agent is to take the mixture of metallic silver and glass and put it into a stirring tank with a temperature of 1400 ° C, and then put all the air in the stirring tank Replaced with nitrogen, mixed and stirred for 2 hours, after the stirring was completed,...

Embodiment 2

[0031] Embodiment 2: Preparation of diatomite molding composition

[0032] The formula is: a diatomite molding composition with moisture absorption function, the weight percentage of each component of the diatomite molding composition is composed of: 20% diatomite, 15% tourmaline powder, 8% zeolite powder, bamboo charcoal 5%, antibacterial agent 5%, acrylic resin adhesive 1.0%, and the balance is gypsum powder. The antibacterial agent is an inorganic antibacterial agent obtained by attaching silver ions to glass. The particle size of diatomite is 25 μm, and the particle size of tourmaline powder The particle size of gypsum powder is 25 μm, and the particle size of bamboo charcoal is 25 μm. The preparation method of antibacterial agent is to take the mixture of metallic silver and glass and put it into a stirring tank with a temperature of 1700 ° C, and then put all the air in the stirring tank Replaced with nitrogen, mixed and stirred for 4 hours, after the stirring was comple...

Embodiment 3

[0038] Embodiment 3: Preparation of diatomite molding composition

[0039] The formula is: a diatomite molding composition with moisture absorption function, the weight percentage of each component of the diatomite molding composition is composed of: diatomite 17%, tourmaline powder 12%, zeolite powder 6%, bamboo charcoal 4%, antibacterial agent 4%, acrylic resin adhesive 0.6%, and the balance is gypsum powder. The antibacterial agent is an inorganic antibacterial agent obtained by attaching silver ions to glass. The particle size of diatomite is 22 μm, and the particle size of tourmaline powder The particle size of gypsum powder is 22 μm, and the particle size of bamboo charcoal is 22 μm. The preparation method of antibacterial agent is to put the mixture of metallic silver and glass into a stirring tank with a temperature of 1500 ° C, and then completely remove the air in the stirring tank. Replaced with nitrogen, mixed and stirred for 3 hours, after the stirring was completed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com