A kind of alkaline chemical mechanical polishing fluid

A chemical machinery, polishing liquid technology, applied in other chemical processes, chemical instruments and methods, polishing compositions containing abrasives, etc., can solve the problem of not being able to use metal materials for polishing, and achieve the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The advantages of the present invention are further described below through specific examples, but the protection scope of the present invention is not limited only to the following examples.

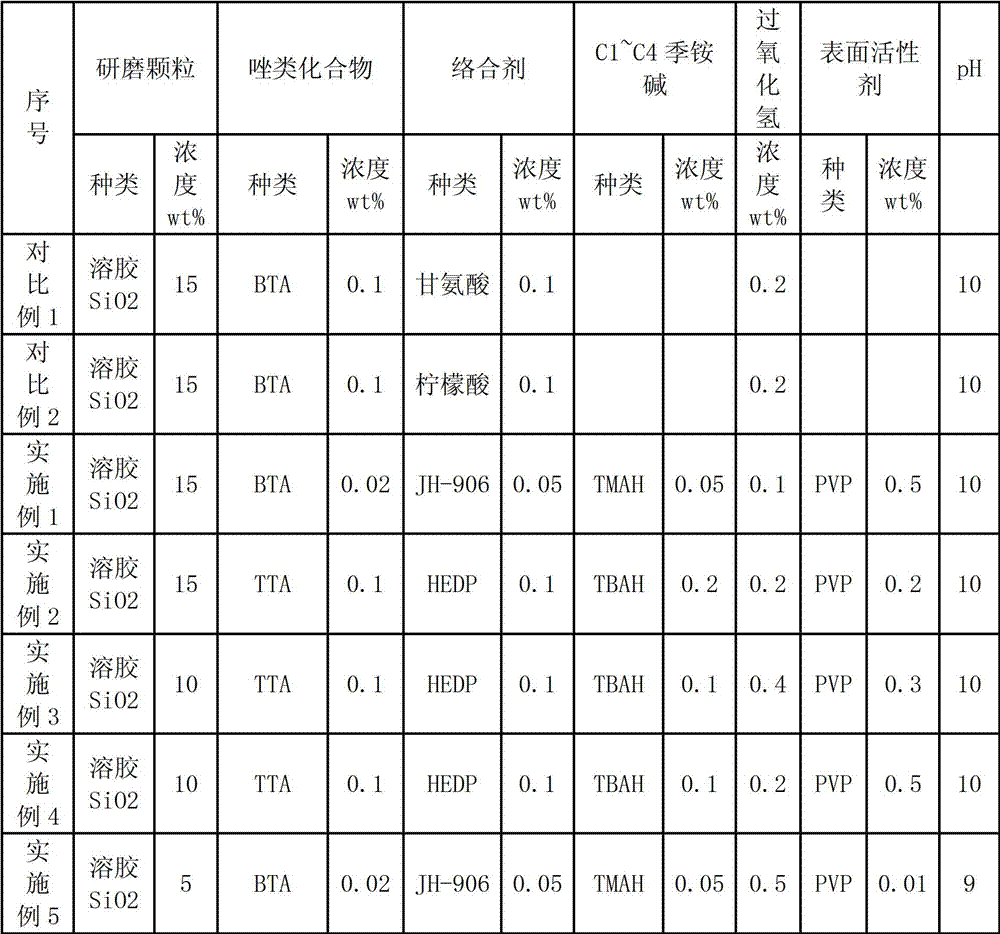

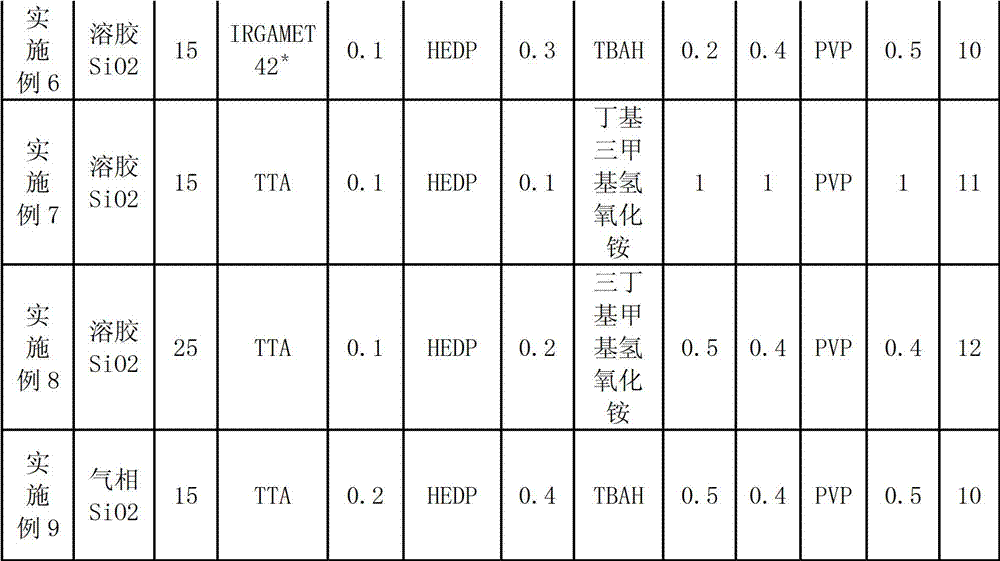

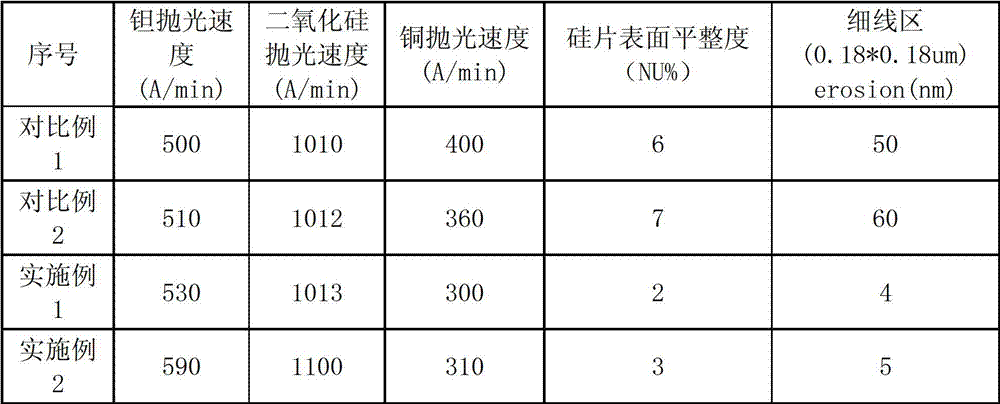

[0037] The polishing liquid was prepared according to the ingredients and proportions of each embodiment in Table 1, and mixed evenly.

[0038] The formula of table 1 embodiment 1-9 of the present invention and comparative example 1-2

[0039]

[0040]

[0041] (where, IRGAMET42 * is TTA derivative) (TTA is tolyltriazole, commercially available)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com