Pearlescent ink, and preparation method and printing method thereof

A pearlescent ink and pearlescent powder technology, applied in printing, ink, printing device, etc., can solve the problems that pearlescent ink cannot meet the requirements of gravure printing and is difficult, and achieve good printing effect, no bad printing, and avoid mechanical damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] Correspondingly, the present invention also discloses a preparation method of pearlescent ink, comprising: pre-mixing and soaking pearlescent powder I, pearlescent powder II, pearlescent powder III and n-propyl ester; first adding nitrocellulose resin liquid, Wetting and dispersing agent, stirring at low speed for 5-30 minutes; then under low-speed stirring, add the pre-soaked pearl powder Ⅰ, pearl powder Ⅱ and pearl powder Ⅲ in sequence, and stir at 1000-1500 rpm for 5-20 minutes; then add Stir the anti-sedimentation agent evenly; finally filter with a filter screen to obtain the finished pearlescent ink of the present invention.

[0064] Preferably, the pre-mixed soaking time of the pearl powder I, pearl powder II, pearl powder III and n-propyl ester is 1-5 hours; the stirring time of the nitrocellulose resin liquid and the wetting and dispersing agent is 15 minutes; the The stirring time of pearl powder I, pearl powder II and pearl powder III is 10 minutes.

[0065]...

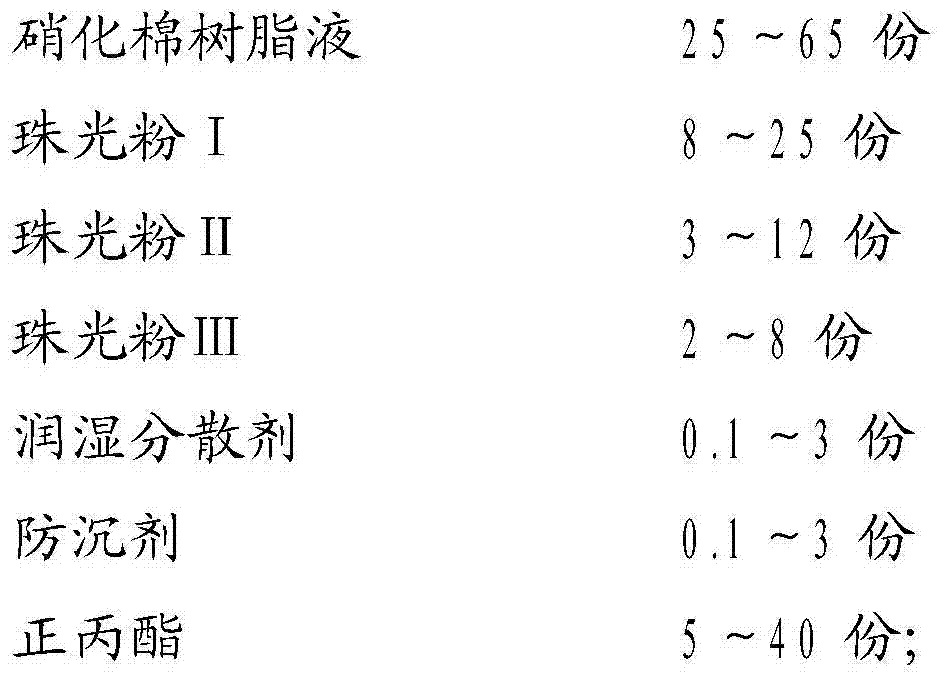

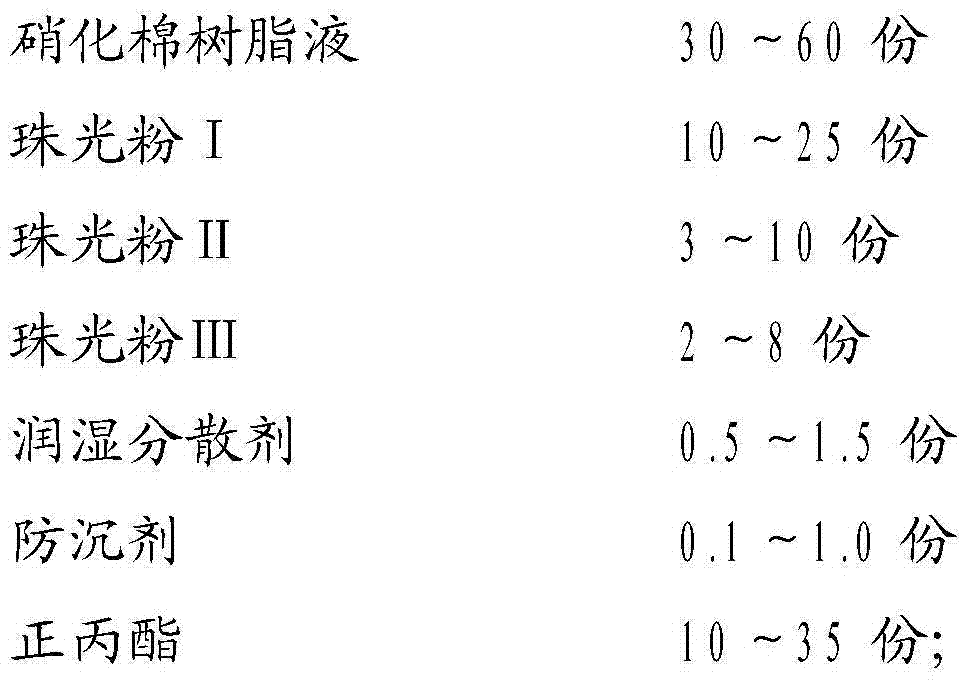

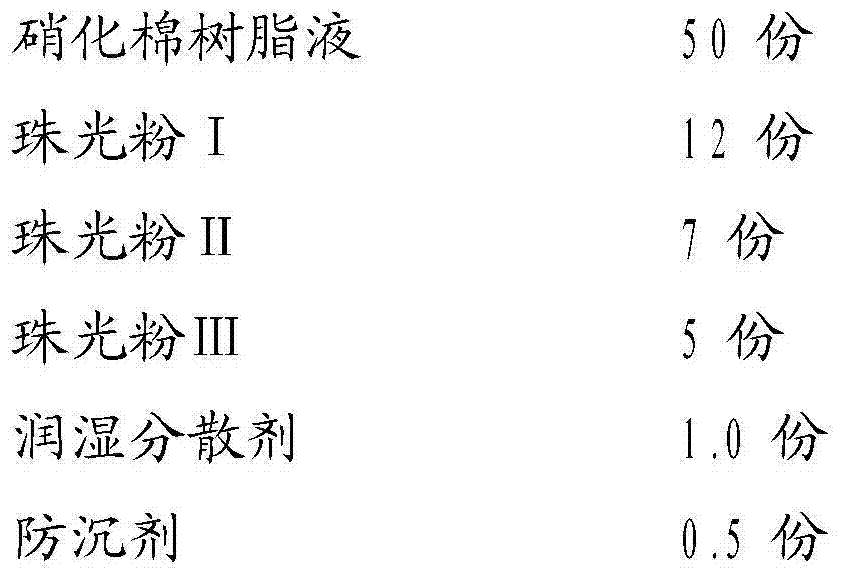

Embodiment 1

[0084] 1. Raw materials: 25 parts of nitrocellulose resin liquid, 25 parts of pearl powder I (with a particle size of 700 mesh to 1500 mesh), 12 parts of pearl powder II (with a particle size of 500 mesh to 1000 mesh), 12 parts of pearl powder III (with a particle size of 300 mesh to 700 mesh) 8 parts, 2 parts of wetting and dispersing agent, 2 parts of anti-sedimentation agent, 26 parts of n-propyl ester.

[0085] 2. Preparation method: pre-mix and soak pearl powder Ⅰ, pearl powder Ⅱ, pearl powder Ⅲ and n-propyl ester for 1 hour; add nitrocellulose resin solution, wetting and dispersing agent in turn in ink production, and stir at low speed for 15 minutes; then Under low-speed stirring, add pre-soaked pearl powder Ⅰ, pearl powder Ⅱ and pearl powder Ⅲ in sequence, and stir at 1000-1500 rpm for 10 minutes; then add anti-settling agent and stir well; finally filter with a 200-mesh filter to obtain The pearlescent ink finished product of the present invention.

Embodiment 2

[0087] 1. Raw materials: 45 parts of nitrocellulose resin liquid, 14 parts of pearl powder I (with a particle size of 800 mesh to 1400 mesh), 8 parts of pearl powder II (with a particle size of 500 mesh to 900 mesh), 8 parts of pearl powder III (with a particle size of 400 mesh to 700 mesh) 7 parts, wetting and dispersing agent 1.2 parts, anti-sedimentation agent 0.4 parts, n-propyl ester 24.4 parts.

[0088] 2. Preparation method: pre-mix and soak pearl powder Ⅰ, pearl powder Ⅱ, pearl powder Ⅲ and n-propyl ester for 2 hours; add nitrocellulose resin solution, wetting and dispersing agent in sequence in the production of ink, and stir for 15 minutes at low speed; then Under low-speed stirring, add pre-soaked pearl powder Ⅰ, pearl powder Ⅱ and pearl powder Ⅲ in sequence, and stir at 1000-1500 rpm for 10 minutes; then add anti-settling agent and stir well; finally filter with a 200-mesh filter to obtain The pearlescent ink finished product of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com