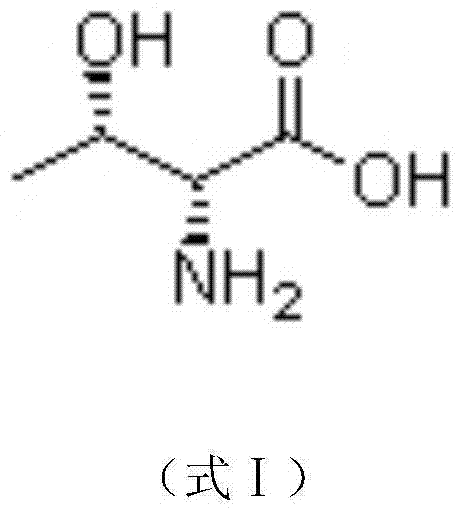

Preparation method of D-threonine

A technology of threonine and copper threonine, which is applied in the field of preparation of D-threonine, can solve the problems of low DL-threonine yield, low total yield and high cost, and achieves a simple synthetic route and easy manual operation. The effect of high sexual content and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

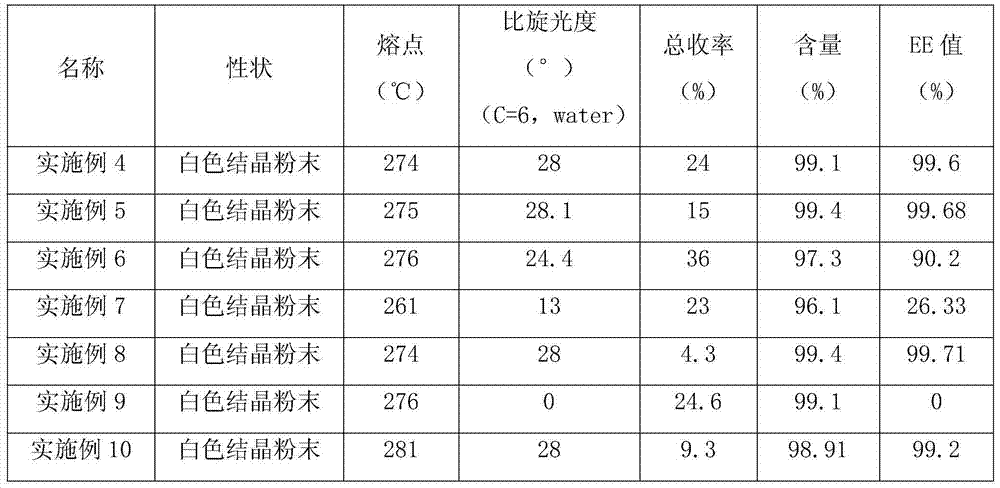

Examples

Embodiment 1

[0025] Embodiment 1: the preparation method of D-threonine, it comprises the following steps:

[0026] S1. Synthesis:

[0027] A. Dissolve glycine with a purity of 97% in 2mol / L sodium hydroxide solution, heat up to 65°C, react at a constant temperature for 6h, cool to room temperature, centrifuge, and dry to obtain copper glycine; wherein, glycine: hydroxide Sodium: the mass ratio of copper sulfate pentahydrate is 1:5:1.4;

[0028] B. Dissolve copper glycinate in water, add S-2-(diphenylhydroxymethyl)-tetrahydropyrrole, cool to 5°C, add acetaldehyde dropwise, react for 20 hours, D-threonine copper salt precipitates, separate solid Material, clean solid matter with 70% ethanol, remove lotion, get D-threonine copper salt; Wherein, copper glycinate: water: D-proline derivative: the mass ratio of acetaldehyde is 0.9:6:0.1: 1;

[0029] S2. Desalination: Dissolve D-threonine copper salt obtained in step S1 in 8% ammonia water, use hydrogen-type 732 cationic ammonia-type resin to...

Embodiment 2

[0031] Embodiment 2: the preparation method of D-threonine, it comprises the following steps:

[0032] S1. Synthesis:

[0033] A. Dissolve glycine with a purity of 98% in 2mol / L sodium hydroxide solution, heat up to 75°C, react at a constant temperature for 8h, cool to room temperature, centrifuge, and dry to obtain copper glycine; wherein, glycine: hydroxide Sodium: the mass ratio of copper sulfate pentahydrate is 1.05:6:1.6;

[0034] B. Dissolve copper glycinate in water, add N-triphenylmethyl-(L)-proline, cool to 10°C, add acetaldehyde dropwise, react for 28 hours, D-threonine copper salt precipitates, and separate solid matter , clean the solid matter with 80% ethanol, remove the lotion, and get D-threonine copper salt; wherein, copper glycinate: water: D-proline derivative: the mass ratio of acetaldehyde is 1:7:0.15:1.5 ;

[0035] S2. Desalination: Dissolve D-threonine copper salt obtained in step S1 in 12% ammonia water, use hydrogen-type 732 cationic ammonia-type res...

Embodiment 3

[0037] Embodiment 3: the preparation method of D-threonine, it comprises the following steps:

[0038] S1. Synthesis:

[0039] A. Dissolve glycine with a purity of 98.5% in 2mol / L sodium hydroxide solution, heat up to 70°C, react at a constant temperature for 7h, cool to room temperature, centrifuge, and dry to obtain copper glycine; wherein, glycine: hydroxide Sodium: the mass ratio of copper sulfate pentahydrate is 1.02:5.5:1.5;

[0040] B. Dissolve copper glycinate in water, add N-triphenylmethyl-(L)-proline, cool to 8°C, add acetaldehyde dropwise, react for 25 hours, D-threonine copper salt precipitates, and separates solid matter , clean solid matter with 76% ethanol, remove lotion, get D-threonine copper salt; Wherein, copper glycinate: water: D-proline derivative: the mass ratio of acetaldehyde is 0.95:6.8:0.12:1.3 ;

[0041] S2. Desalination: Dissolve D-threonine copper salt obtained in step S1 in 10% ammonia water, use hydrogen-type 732 cationic ammonia-type resin to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com