Freezing-proof bituminous mixture as well as preparation method and construction method thereof

An asphalt mixture and construction method technology, applied in the engineering field, can solve the problems of finding lines, large maintenance works, road peeling and damage to the environment, corrosion of steel fibers and other problems, so as to achieve sustainable development and ensure smooth roads and driving. Safe and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

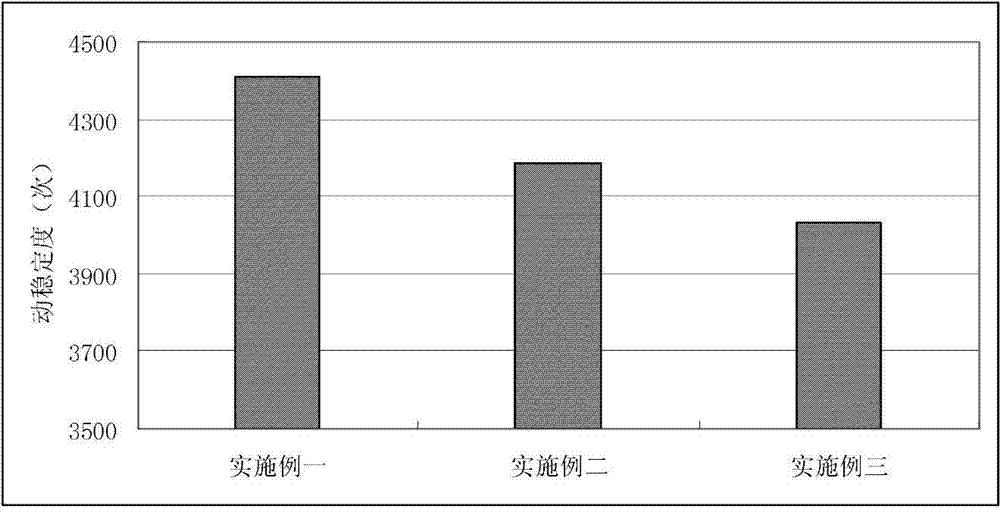

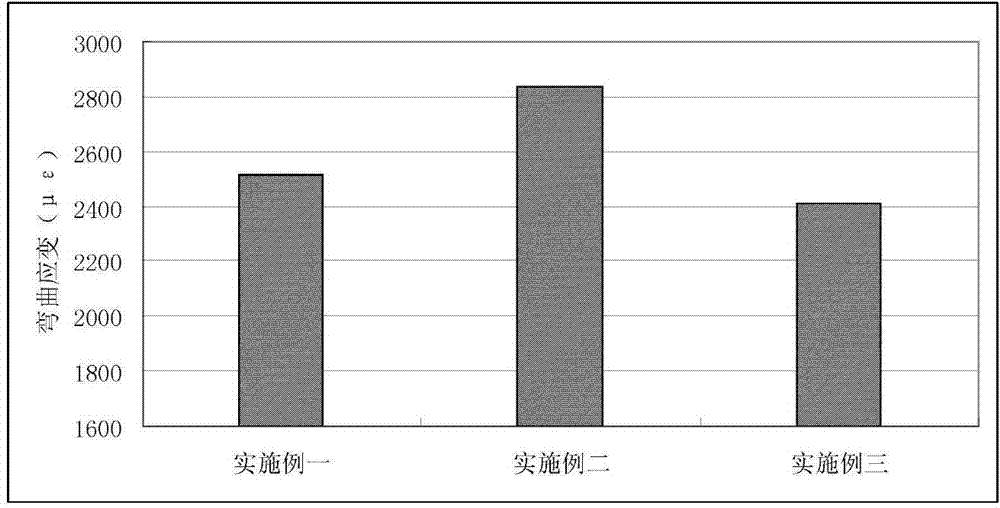

Embodiment 1

[0028] 1. Material preparation:

[0029] The asphalt is modified asphalt, and the SBS modified asphalt produced by Jiangsu Baoli Asphalt Co., Ltd. is used in this embodiment.

[0030] Crushed stone aggregate, also known as aggregate. One of the main components of asphalt concrete, it mainly acts as a skeleton and reduces the volume change caused by the shrinkage and swelling of the cementitious material during the setting and hardening process, and is also used as a cheap filler for the cementitious material. There are natural aggregates and artificial aggregates, the former such as gravel, pebbles, pumice, natural sand, etc.; the latter such as cinder, slag, ceramsite, expanded perlite, etc. The stone material used in this example is sieved crushed stone, and the crushed stone aggregate is classified according to the commonly used classification requirements. 9.5 ~ 16mm, the ratio of each file is: 24.50% : 13.00% : 34.00% : 28.50%, when adding it is added at the same time. ...

Embodiment 2

[0041] 1. Material preparation:

[0042] The asphalt is modified asphalt, and the SBS modified asphalt produced by Nantong Tongsha Asphalt Technology Co., Ltd. is used in this embodiment.

[0043] For crushed stone aggregates, the crushed stone aggregates are graded according to the commonly used classification requirements. The grades used in this embodiment are: 0-2.36mm, 2.36-4.75mm, 4.75-9.5mm and 9.5-16mm. The ratio is: 27.00% : 12.00% : 32.50% : 28.50%, and they are added at the same time.

[0044] Limestone slag, mainly composed of calcium carbonate, requires limestone slag processed from limestone.

[0045] Mafilon is a powdery solid similar to ore powder sold by Japan Liangyuan Commercial Co., Ltd.

[0046] Mafilon 6%

[0047] Bitumen 4.94%

[0048] Crushed stone aggregate 89.06%

[0049] 2. Prepare the antifreeze asphalt mixture with the above materials according to the following steps:

[0050] Step 1: After heating the gravel aggregate to 200±5°C, dry mix it ...

Embodiment 3

[0054] 1. Material preparation:

[0055] The asphalt is modified asphalt, and the SBS modified asphalt produced by Nantong Tongsha Asphalt Technology Co., Ltd. is used in this embodiment.

[0056] For crushed stone aggregates, the crushed stone aggregates are graded according to the commonly used classification requirements. The grades used in this embodiment are: 0-2.36mm, 2.36-4.75mm, 4.75-9.5mm and 9.5-16mm. The ratio is: 27.50% : 11.50% : 32.40% : 28.60%, and they are added at the same time.

[0057] Limestone slag, mainly composed of calcium carbonate, requires limestone slag processed from limestone.

[0058] Mafilon is a powdery solid similar to ore powder sold by Japan Liangyuan Commercial Co., Ltd.

[0059] Mafilon 7%

[0060] Bitumen 4.85%

[0061] Crushed stone aggregate 88.15%

[0062] 2. Prepare the antifreeze asphalt mixture with the above materials according to the following steps:

[0063] Step 1: After heating the gravel aggregate to 200±5°C, dry mix it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com