Hilly and mountainous area reinforcement cage stalagmite pile and construction process thereof

A construction technology and steel cage technology, applied in sheet pile walls, foundation structure engineering, roads, etc., can solve the problems of poor subgrade stability, easy deformation and settlement, etc., and achieve the reduction of compressibility, improvement of compactness, and increase of strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the objectives, technical solutions, and advantages of the present invention clearer and more comprehensible, the present invention will be further described in detail with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many details listed in the specification are only to enable the reader to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

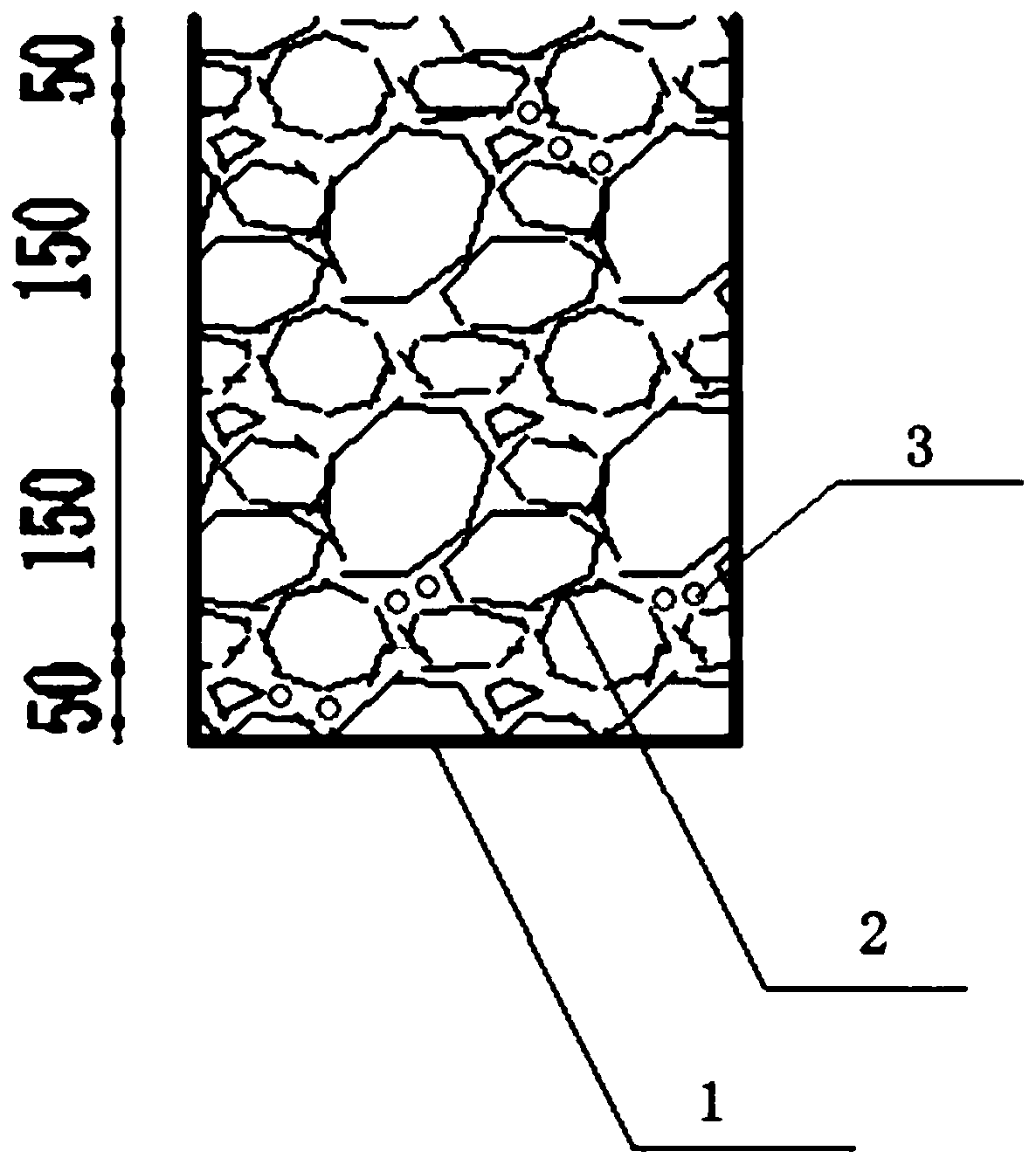

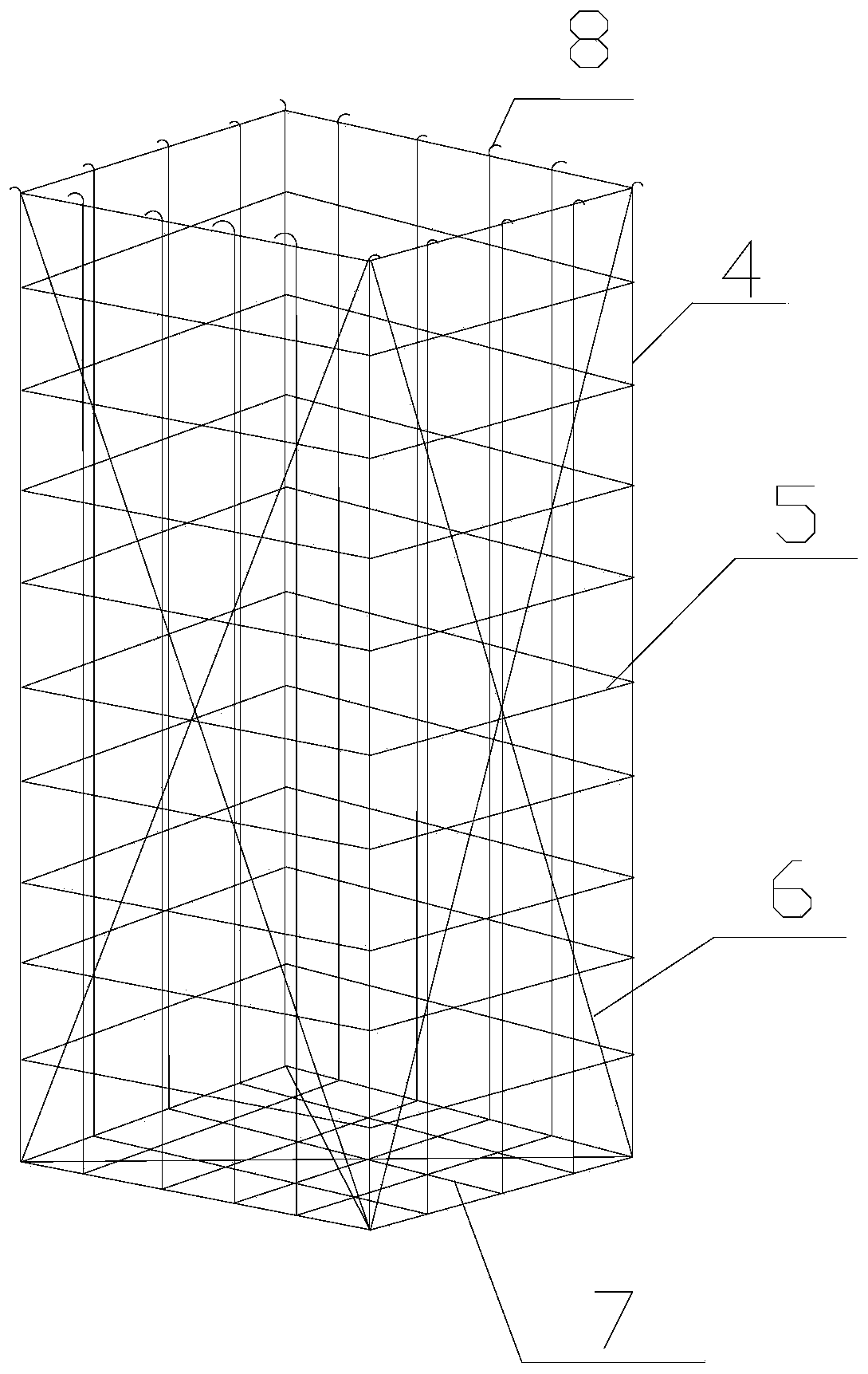

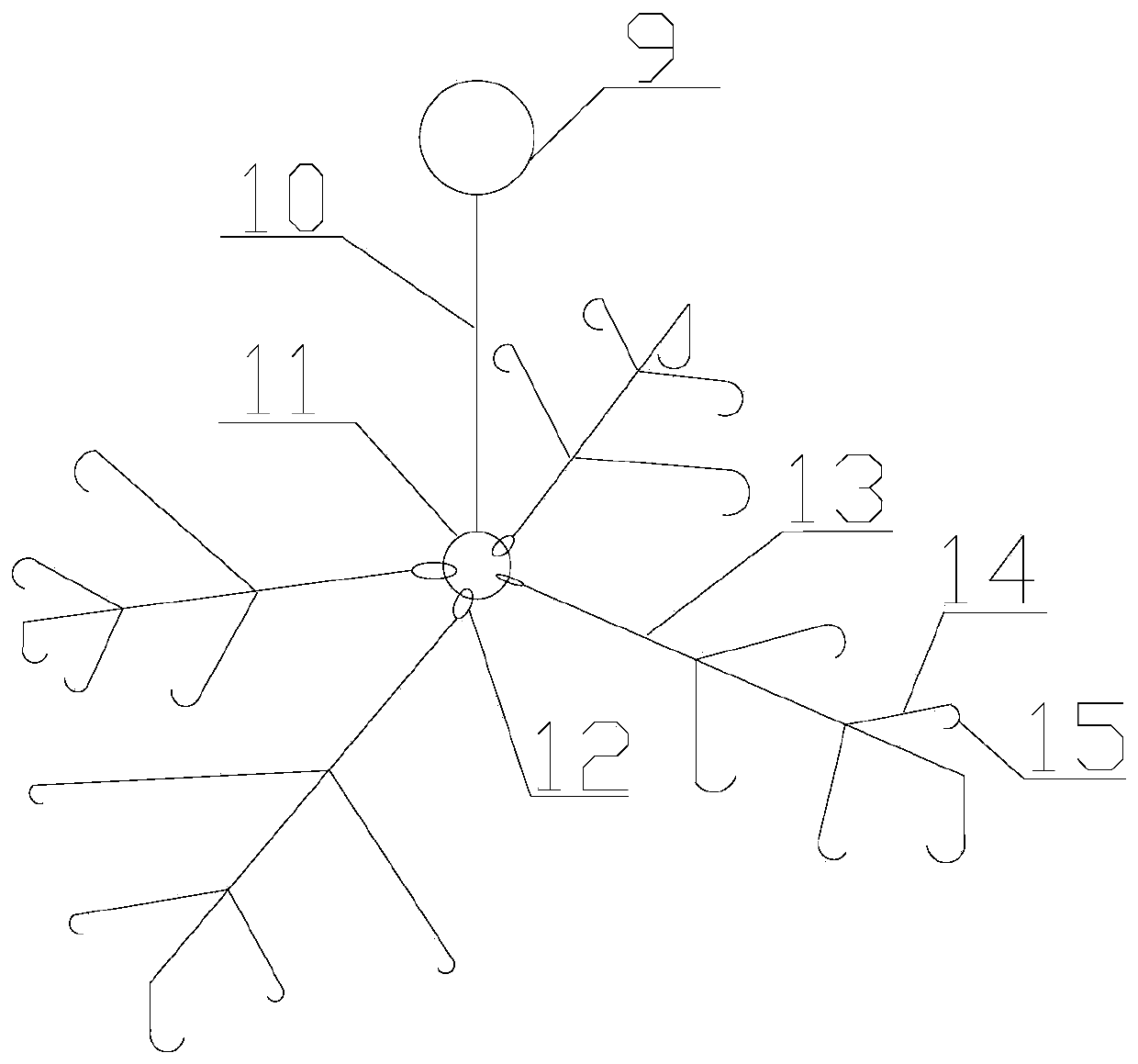

[0039] See figure 1 , The present invention provides a reinforced cage stalagmite pile in a heavy hilly mountain area, comprising a reinforced cage 1, a stone material 2 and a gravel soil 3. The reinforced cage 1 is sleeved into a foundation pit of a soft soil roadbed, the stone material 2 and the gravel soil 3 are filled into the steel cage 1. Stalagmite piles have compacting, vibrating, replacement and accelerated consolidation effects on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com