Chemical industry wastewater purifying agent and preparation method thereof

A technology for chemical wastewater and purifying agent, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as human harm, achieve good purification effect, good removal effect, and prevent pollution water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

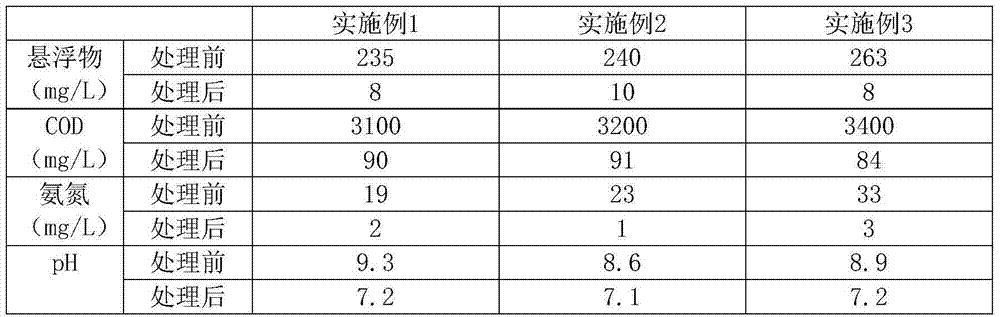

Examples

Embodiment 1

[0011] A chemical wastewater purification agent, comprising the following raw materials in parts by weight: 10 parts of aluminum oxide, 20 parts of decanal, 20 parts of calcium oxide, 7 parts of sulfur, 36 parts of activated carbon, 10 parts of polyacrylamide, and 20 parts of cobalt oxide , 20 parts of sodium carboxymethyl cellulose, 25 parts of polyoxyethylene propylene glycol monostearate, 5 parts of camphor, 30 parts of sodium lauryl sulfonate, 10 parts of hexamethylenetetramine, surfactant alkyl 20 parts of phenol polyoxyethylene ether.

[0012] The preparation method of the chemical wastewater purifying agent includes the following steps: uniformly mixing all raw materials, heating to 40° C. for 1 hour reaction, and then cooling to room temperature.

Embodiment 2

[0014] A chemical wastewater purification agent, comprising the following raw materials in parts by weight: 20 parts of aluminum oxide, 22 parts of decanal, 23 parts of calcium oxide, 9 parts of sulfur, 38 parts of activated carbon, 15 parts of polyacrylamide, and 25 parts of cobalt oxide , 23 parts of sodium carboxymethyl cellulose, 29 parts of polyoxyethylene propylene glycol monostearate, 8 parts of camphor, 40 parts of sodium laurylsulfonate, 20 parts of hexamethylenetetramine, surfactant fatty alcohol 35 parts of polyoxyethylene ether calcium sulfate.

[0015] The preparation method of the chemical wastewater purifying agent includes the following steps: uniformly mixing all raw materials, heating to 50° C. for 1.5 hours, and then cooling to room temperature.

Embodiment 3

[0017] A chemical wastewater purification agent, comprising the following raw materials in parts by weight: 30 parts of aluminum oxide, 30 parts of decanal, 25 parts of calcium oxide, 10 parts of sulfur, 40 parts of activated carbon, 20 parts of polyacrylamide, and 30 parts of cobalt oxide , 25 parts of sodium carboxymethyl cellulose, 30 parts of polyoxyethylene propylene glycol monostearate, 10 parts of camphor, 50 parts of sodium lauryl sulfonate, 30 parts of hexamethylenetetramine, surfactant alkyl 39 parts of phenol polyoxyethylene ether.

[0018] The preparation method of the chemical wastewater purifying agent includes the following steps: uniformly mixing all raw materials, heating to 60° C. for 2 hours, and then cooling to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com