A high-precision frame for aircraft assembly tooling and its processing method

An assembly tooling and processing method technology, applied in the field of mechanical processing, can solve the problems of multiple gaps on the connecting surface, difficult adjustment, poor interchangeability, etc., so as to prolong the service life and reliability, facilitate transportation, prevent micro-deformation and ever-changing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

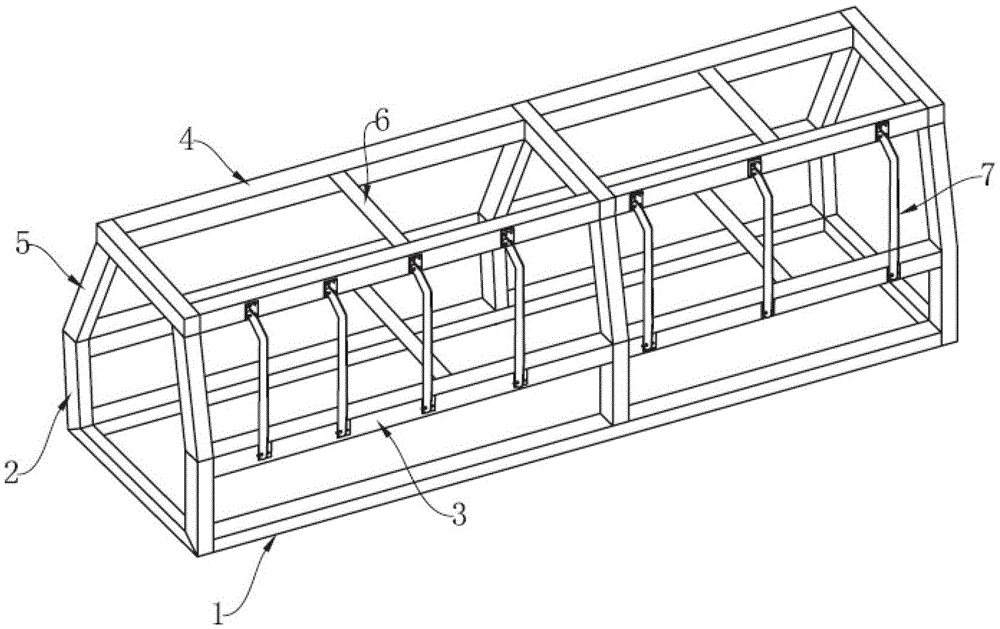

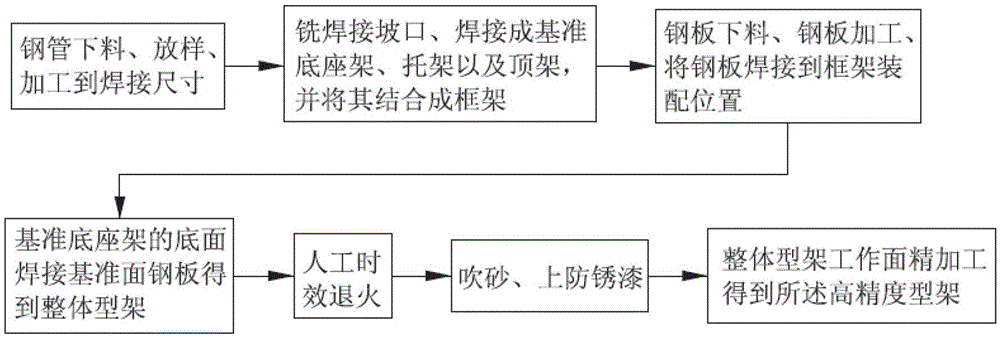

[0057] Embodiment 1, the processing method of the high-precision jig for large-scale helicopter assembly tooling, comprises the following steps, S1, steel pipe blanking, lofting, processing to welding size;

[0058] S2. Milling the welding groove, according to the groove of 30 degrees and 10mm from the periphery of the groove, that is, the angle of the groove is 30 degrees and the length is 10mm, which can ensure uniform welding seam and welding stress, so that all positions of the welding frame The deformation range and gap are reduced, and the strength and rigidity of the welded frame without groove are greatly improved; the base frame, bracket and top frame are welded and combined into a frame;

[0059] S3, steel plate blanking, steel plate processing, welding the steel plate to the frame assembly position;

[0060] S4. The bottom surface of the reference base frame is welded with a reference plane steel plate to obtain an integral frame;

[0061] S5. Artificial aging anne...

Embodiment 2

[0076] Embodiment 2, is used for the processing method of the high-precision type frame of small business aircraft assembly tooling, comprises the following steps, S1, steel pipe blanking, lofting, processing to welding size;

[0077] S2. Milling the welding groove, according to the groove of 30 degrees and 10mm from the periphery of the groove, that is, the angle of the groove is 30 degrees and the length is 10mm, which can ensure uniform welding seam and welding stress, so that all positions of the welding frame The deformation range and gap are reduced, and the strength and rigidity of the welded frame without groove are greatly improved; the base frame, bracket and top frame are welded and combined into a frame;

[0078] S3, steel plate blanking, steel plate processing, welding the steel plate to the frame assembly position;

[0079] S4. The bottom surface of the reference base frame is welded with a reference plane steel plate to obtain an integral frame;

[0080] S5. Ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com