Polishing medium, polishing equipment and method for removing burrs on surface of metal part

A technology for polishing media and metal parts, applied in the field of polishing, can solve the problems of polishing media damage to the surface of metal parts, metal parts becoming brittle, and high processing costs, and achieve the effects of speeding up operation efficiency, reducing processing costs, and cheap prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings of the description.

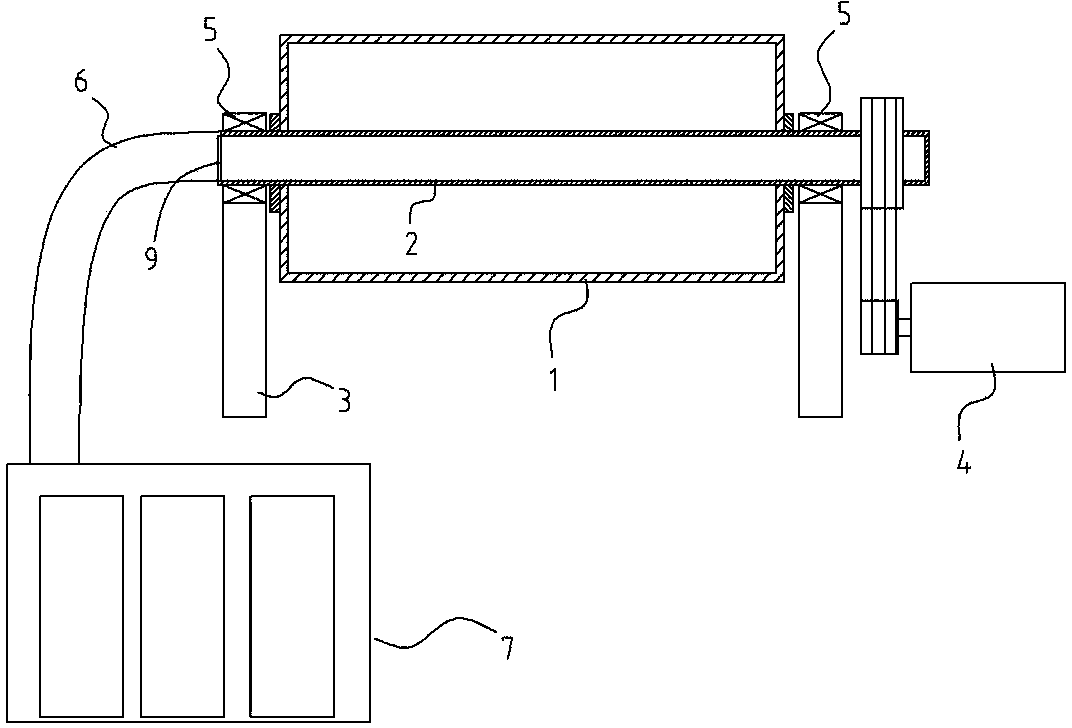

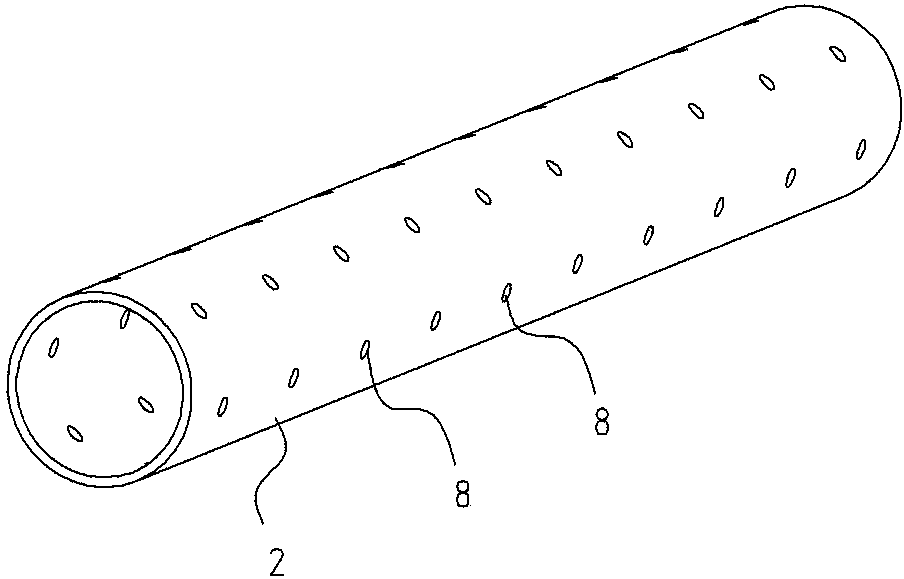

[0023] Such as figure 1 As shown, a method for removing burrs on the surface of metal parts, the present invention is combined with polishing equipment to automatically complete the removal of burrs on the surface of metal parts. The polishing equipment includes a closed cylinder 1 and a motor 4 that drives the rotation of the cylinder 1; the cylinder 1 is provided with a hollow pivot shaft 2, and the two ends of the pivot shaft 2 extend out of the cylinder 1 and pass through the bearing 5 is fixed on the frame 3, the pivot shaft 2 is fixedly connected with the drum 1, and the motor 4 drives the pivot shaft 2 through a belt to rotate the drum 1; the drum 1 is placed horizontally for accommodating Metal parts and polishing medium for deburring, the polishing medium of the present invention is rice husk, when the drum 1 rotates, the metal parts and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com