Gas cutting tool capable of guaranteeing circular degree

A gas cutting and tool technology, applied in the field of gas cutting tools, can solve the problems of affecting the cutting roundness of circular workpieces, unable to identify plates, secondary cutting of workpieces, etc., and achieve the effects of saving raw materials, simple and convenient positioning, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

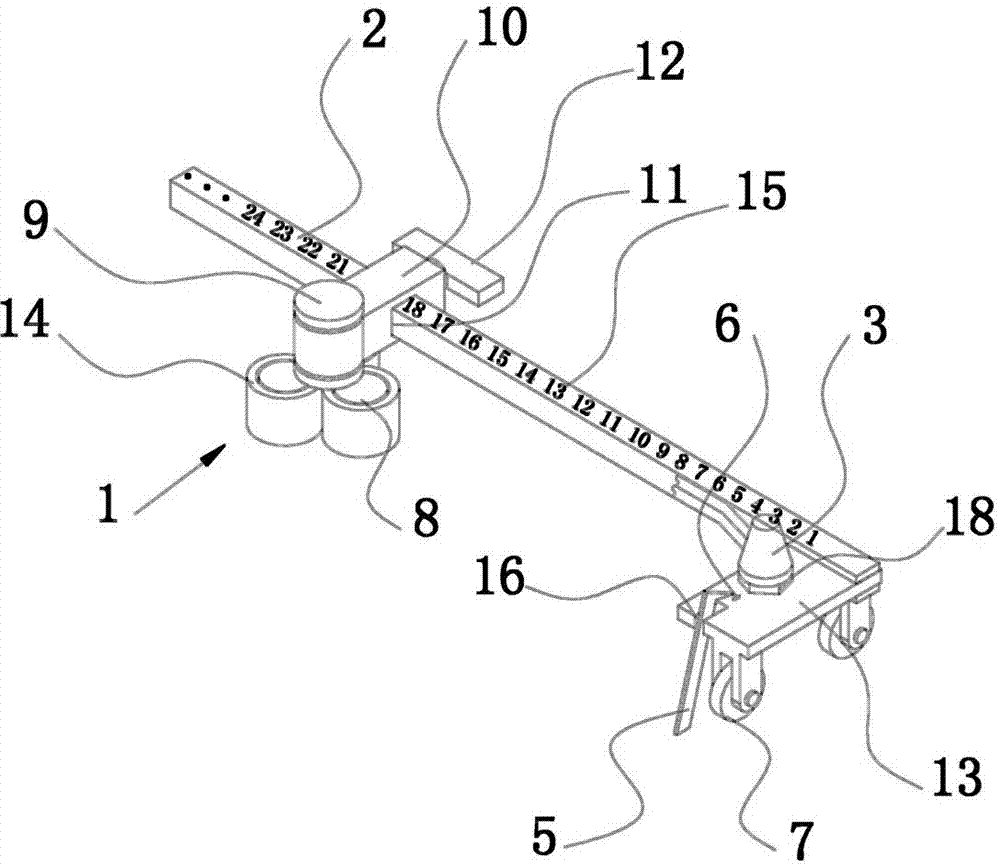

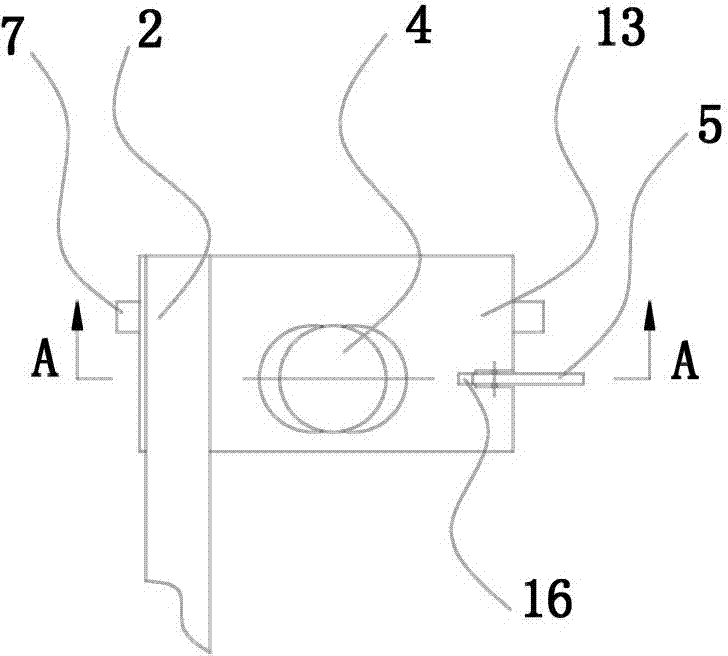

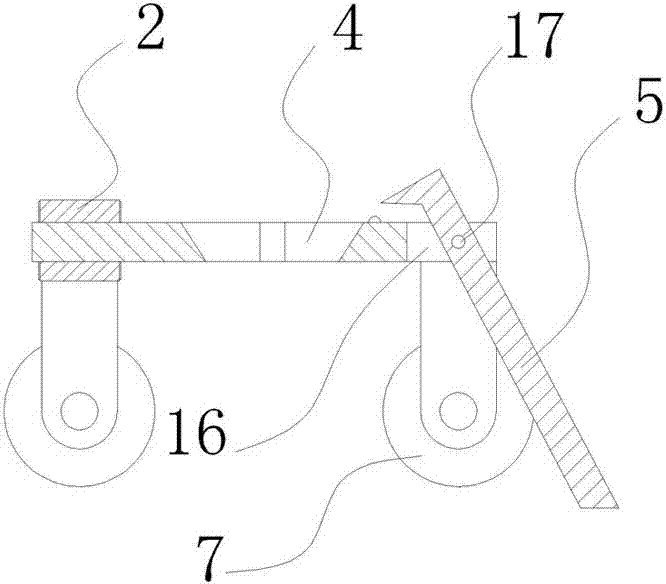

[0026]When in use, fix the positioning seat 1 on the surface of the plate with a thickness of 20 mm, adjust the support arm 2 back and forth to the radius length of the cut circular workpiece, and adjust the adjustment nut 18 to keep the torch head 3 and the surface of the plate at a suitable distance. After igniting the torch head 3 and plugging its burning end downward into the middle positioning hole 4 of the torch head to start gas cutting, then turn the support arm 2 counterclockwise at a constant speed, the pull plate 5 is inserted into the gas cutting slit and synchronized with the support arm 2 Move, when the plate is not cut through, the pull plate 5 runs blocked and rotates upwards, and then the pull plate 5 upper end triggers the sensor 6 downwards, and the sensor 6 sends a signal to cut off the oxygen source and the gas source of the torch head 3 immediately.

[0027] The specific embodiments described herein are merely illustrative of the concepts of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com