A kind of preparation method of organic-inorganic hybrid material supporting ruthenium catalyst for synthesizing 1-aminopropanol

A hybrid material, ruthenium catalyst technology, applied in the preparation of organic compounds, the preparation of aminohydroxy compounds, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of low yield, high cost, large catalyst consumption, etc. problem, to achieve the effect of high activity, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

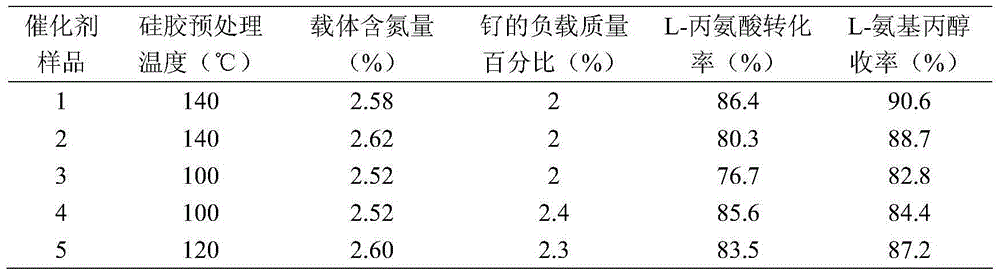

Embodiment 1

[0016] The present embodiment prepares catalyst sample 1 as follows:

[0017] a. Pretreat the silica gel to obtain spare silica gel

[0018] Add 10g of 100-200 mesh silica gel H, 120mL of 98% concentrated sulfuric acid and 15mL of 69% concentrated nitric acid into flask A, and stir in an oil bath at 140°C for 24 hours. Wash the silica gel H several times until the washing liquid is neutral, filter it with suction, take the solid intermediate A, wash the solid intermediate A with ethanol, and then put the filter cake in a vacuum drying oven at 140°C after suction filtration. Conditioned drying for 6 hours to obtain spare silica gel;

[0019] b. Grafting modified ethylenediamine structural units on the surface of spare silica gel

[0020] Add 60 mL of absolute anhydrous toluene and 1.4 g of N-(3-triethoxysilylpropyl) ethylenediamine to flask B, stir at room temperature for 30 min, then add 4 g of the spare silica gel obtained in step a, and stir until The spare silica gel is ...

Embodiment 2

[0024] This embodiment prepares catalyst sample 2 in the same manner as in Example 1, and changes the quality of N-(3-triethoxysilylpropyl) ethylenediamine into 1.8g in step b, and the obtained in step b The spare silica gel modified with ethylenediamine structural units on the surface has a mass percentage of nitrogen of 2.62% as measured by elemental analysis.

Embodiment 3

[0026] The present embodiment prepares catalyst sample 3 as follows:

[0027] a. Pretreat the silica gel to obtain spare silica gel

[0028] Add 10g of 100-200 mesh silica gel H, 120mL of 98% concentrated sulfuric acid and 15mL of 69% concentrated nitric acid into flask A, and stir in an oil bath at 100°C for 24 hours. Wash the silica gel H several times until the washing liquid is neutral, and filter with suction to obtain the solid intermediate A, wash the solid intermediate A with ethanol, and then place the filter cake in a vacuum drying oven at 140°C after suction filtration. Dry for 7 hours to obtain spare silica gel;

[0029] b. Grafting modified ethylenediamine structural units on the surface of spare silica gel

[0030] Add 80 mL of absolute anhydrous toluene and 1.4 g of N-(3-triethoxysilylpropyl) ethylenediamine to flask B, stir at room temperature for 30 min, then add 4 g of the spare silica gel obtained in step a, and stir until The spare silica gel is uniforml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com