Low-temperature sulfur-tolerant shift catalyst and preparation method thereof

A technology of sulfur-resistant conversion and catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Large volume and other problems, to achieve strong structural stability and anti-hydration performance, good structural stability, and low loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

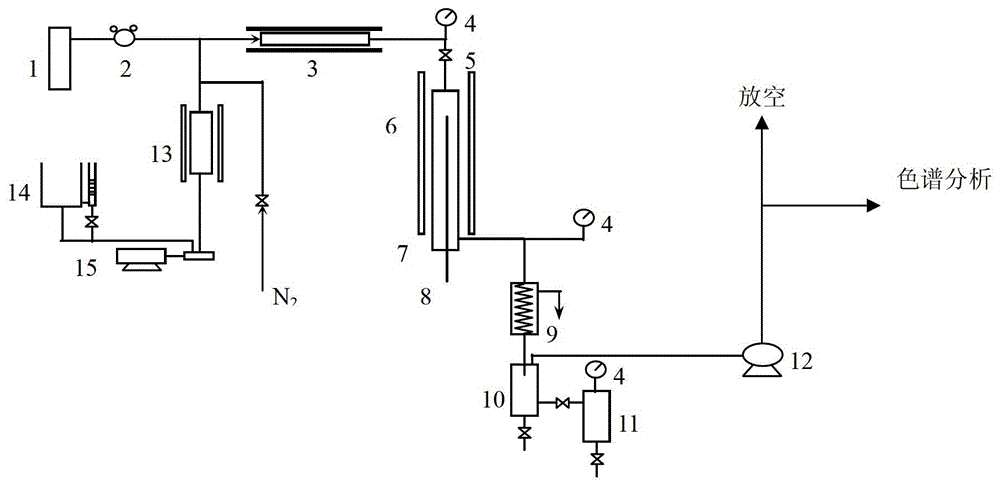

Method used

Image

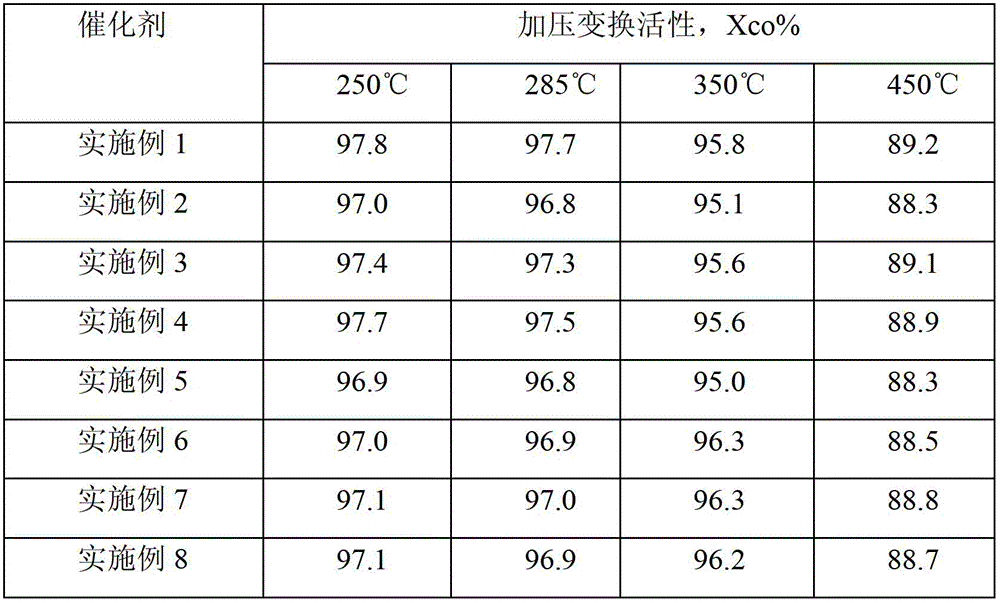

Examples

Embodiment 1

[0061] The attapulgite clay was first calcined at 500°C for 3 hours, and then crushed through a 180-mesh sieve.

[0062] Dissolve 8.61g of ammonium molybdate with 40.0ml of deionized water to obtain solution A containing molybdenum; dissolve 8.82g of cobalt nitrate, 23.34g of nickel nitrate, and 8.82g of potassium carbonate with 45.0ml of deionized water to obtain a solution containing cobalt and nickel B; Dissolve 3.0 g of citric acid in 10 ml of deionized water to obtain solution C.

[0063] Weigh 56.0g of attapulgite clay, 10.0g of magnesia, 15.0g of metatitanic acid, 11.2g of kalephine, and 3.0g of celadon powder, mix them evenly, add solution A, knead evenly, then add solution C, knead evenly, and then form Bar shape, air-dried, baked at 550°C for 3h, and cooled down to room temperature naturally.

[0064] The calcined catalyst was put into the solution B, impregnated with an equal volume, dried, calcined at 420°C for 2 hours, and then cooled down to room temperature nat...

Embodiment 2

[0066] The attapulgite clay was first calcined at 500°C for 4 hours, and then crushed through a 180-mesh sieve.

[0067] Dissolve 9.84g of ammonium molybdate in 30.0ml of deionized water to obtain solution A containing molybdenum; dissolve 1.94g of cobalt nitrate, 31.12g of nickel nitrate and 5.88g of potassium carbonate in 35.0ml of deionized water to obtain solution B containing nickel ; Then 5.0g of citric acid and 2.0g of oxalic acid were dissolved in 10ml of deionized water to obtain solution C.

[0068] Weigh 62.5g of attapulgite clay, 5.0g of magnesia, 12.5g of metatitanic acid, 11.2g of kaleidite, 4.0g of celadon powder and mix evenly, add solution A, knead evenly, then add solution C, knead evenly, and then form Bar shape, air-dried, baked at 600°C for 3h, and cooled down to room temperature naturally.

[0069] Put the calcined catalyst into the solution B, impregnate it in equal volume, dry it, and calcinate it at 450°C for 2 hours, then cool it down to room tempera...

Embodiment 3

[0071] The attapulgite clay was first calcined at 600°C for 2 hours, and then crushed through a 200-mesh sieve.

[0072] Dissolve 5.54g of ammonium molybdate with 30.0ml of deionized water to obtain solution A containing molybdenum; dissolve 7.76g of cobalt nitrate, 27.23g of nickel nitrate, and 1.47g of potassium carbonate with 55.0ml of deionized water to obtain a solution containing cobalt and nickel B; Dissolve 4.0 g of citric acid and 2.0 g of sucrose in 10 ml of deionized water to obtain solution C.

[0073] Weigh 77.5g of attapulgite clay, 1g of magnesia, 6.25g of metatitanic acid, 11.5g of kalephine, and 4.0g of glucose and mix evenly, add solution A, knead evenly, then add solution C, knead evenly, and then form a clover shape, Dry naturally, bake at 500°C for 3h, and cool down to room temperature naturally.

[0074] The calcined catalyst was put into the solution B, impregnated with an equal volume, dried, calcined at 500°C for 3 hours, and then cooled down to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com