Convex lens corrugation type solar cell silicon substrate and manufacturing process thereof

A solar cell and manufacturing process technology, applied in the field of solar cells, can solve the problems of lack of light concentrating performance and large light reflection loss, and achieve the effects of prolonging the effective power generation time, low production cost and reducing reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Such as figure 1 , 2 . As shown in 3, a convex lens type corrugated solar cell monocrystalline silicon substrate includes a monocrystalline silicon substrate body 1, and the surface of the monocrystalline silicon substrate body 1 is a convex lens type corrugated non-planar structure arranged in a strip order .

[0026] The height difference between the top end 2 and the bottom end 3 of the convex lens of the single crystal silicon substrate body 1 ranges from 1 mm to 2 mm.

[0027] The difference in width between the diameters of the bottom surfaces of the convex lenses of the monocrystalline silicon substrate body 1 is in the range of 8-10 mm.

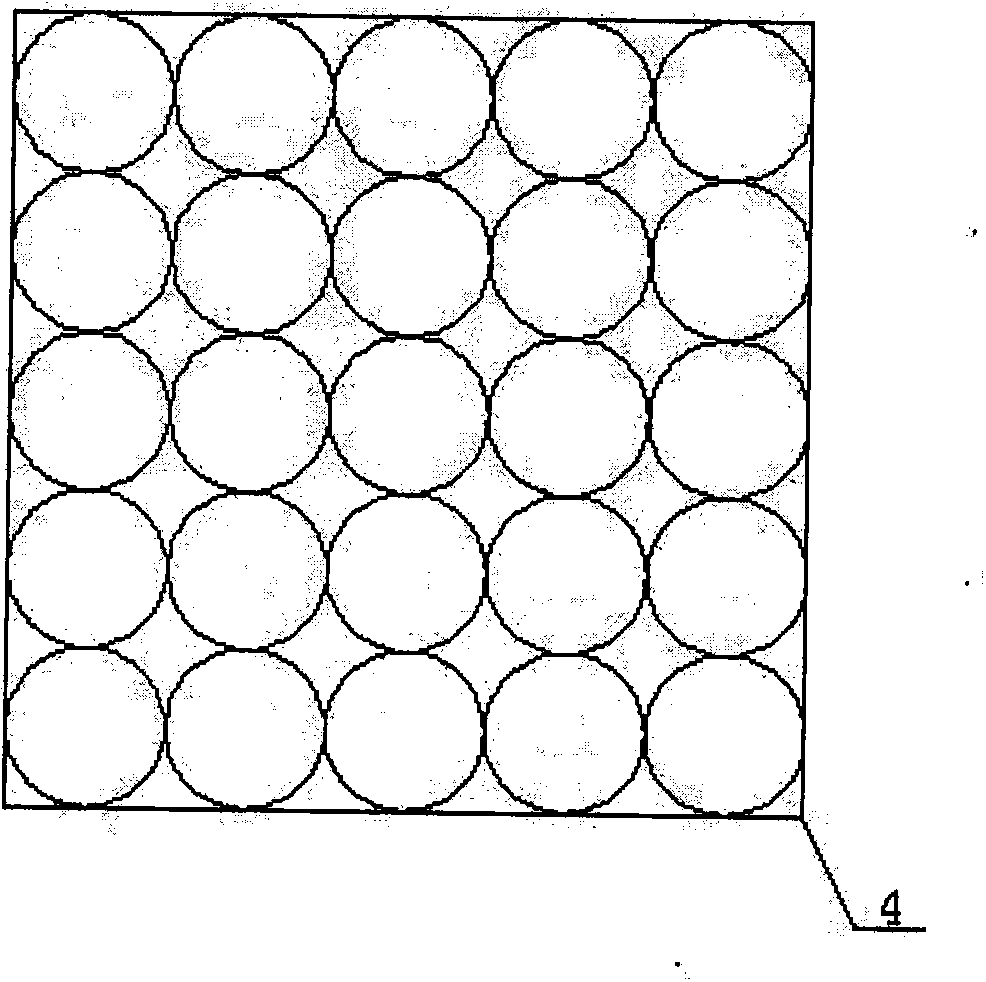

[0028] Such as Figure 4 As shown, a manufacturing process of a convex lens type corrugated solar cell monocrystalline silicon substrate comprises the following steps:

[0029] Step 1. Deposition of an amorphous silicon masking layer: placing a screen 4 with circular windows arranged in strips on the surface of a flat monoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com