Mould-proof antibacterial decorative paper and preparation method thereof

A technology of anti-mildew and anti-bacterial, decorative paper, applied in the field of decorative paper, can solve the problem that decorative paper cannot effectively solve the problem of damp and anti-mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Under stirring, stir and mix 3kg of stearic acid, 1kg of edible alkali and 1kg of borax to obtain a paraffin emulsifier. After melting 10kg of paraffin, add paraffin emulsifier, and add 5kg of cationic starch and 8kg of rosin at 40℃. Obtain mixed liquid 1, add the mixed liquid 1 to 60 kg of pulp fibers, stir uniformly and dry to obtain base paper;

[0029] (2) Mix 7kg of water-based ink and 0.1kg of thickener to obtain mixed liquid 2, coat the mixed liquid 2 on the surface of the base paper, and pass the base paper through a drying tunnel at a temperature of 150°C at a speed of 2m / min;

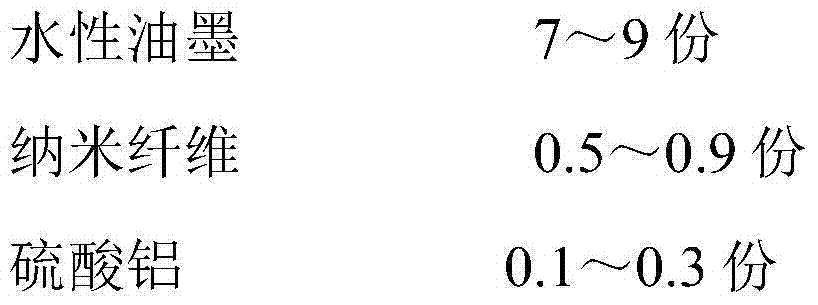

[0030] (3) Mix 0.5kg of ten thousand rubber nanofiber powder, 0.1kg of aluminum sulfate and 3kg of dimethylformamide to obtain a mixed solution 3, spray it on the surface of the base paper just coming out of the drying tunnel in step (2), and then spray it at 8m / min Speed through a drying tunnel at a temperature of 70°C to obtain an anti-mold and anti-bacterial decorative paper.

Embodiment 2

[0032] (1) Under stirring, stir and mix 4kg stearic acid, 0.5kg edible alkali and 0.5kg borax to obtain a paraffin emulsifier. After 22kg of paraffin is melted, add the paraffin emulsifier, and add 10kg cationic starch, 5kg of rosin obtains mixed solution 1, adding this mixed solution 1 to 80kg of pulp fiber, and stir evenly to obtain base paper;

[0033] (2) Mix 9kg of water-based ink and 0.2kg of thickener to obtain mixed liquid 2, coat the mixed liquid 2 on the surface of the base paper, and pass the base paper through a drying tunnel with a temperature of 160℃ at a speed of 3m / min;

[0034] (3) Mix 0.9kg of ten thousand rubber nanofiber powder, 0.3kg of aluminum sulfate and 1kg of dimethylformamide to obtain a mixed solution 3, spray it on the surface of the base paper just coming out of the drying tunnel in step (2), and then spray it at 6m / min Speed through a drying tunnel with a temperature of 80°C to obtain anti-mold and anti-bacterial decorative paper.

Embodiment 3

[0036] (1) Under stirring, stir and mix 2kg stearic acid, 0.8kg edible alkali and 0.8kg borax to obtain a paraffin emulsifier. After melting 10-22 parts of paraffin wax, add paraffin emulsifier and add 8kg at 45℃. Cationic starch and 6 kg of rosin are used to obtain mixed solution 1. Add the mixed solution 1 to 70 kg of pulp fibers and stir to obtain base paper;

[0037] (2) Mix 8 kg of water-based ink and 0.15 kg of thickener to obtain mixed liquid 2, coat the mixed liquid 2 on the surface of the base paper, and pass the base paper through a drying tunnel at a temperature of 155°C at a speed of 2m / min;

[0038] (3) Mix 0.8kg of ten thousand rubber nanofiber powder, 0.2kg of aluminum sulfate and 2kg of dimethylformamide to obtain a mixed solution 3, spray it on the surface of the base paper just coming out of the drying tunnel in step (2), and then spray it at 7m / min Speed through a drying tunnel at a temperature of 75°C to obtain an anti-mold and anti-bacterial decorative paper....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com