A ceramic circuit board fixture for electroplating

A ceramic circuit board and fixture technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problem of broken circuit boards and other problems, and achieve the effect of increasing the area, convenient operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

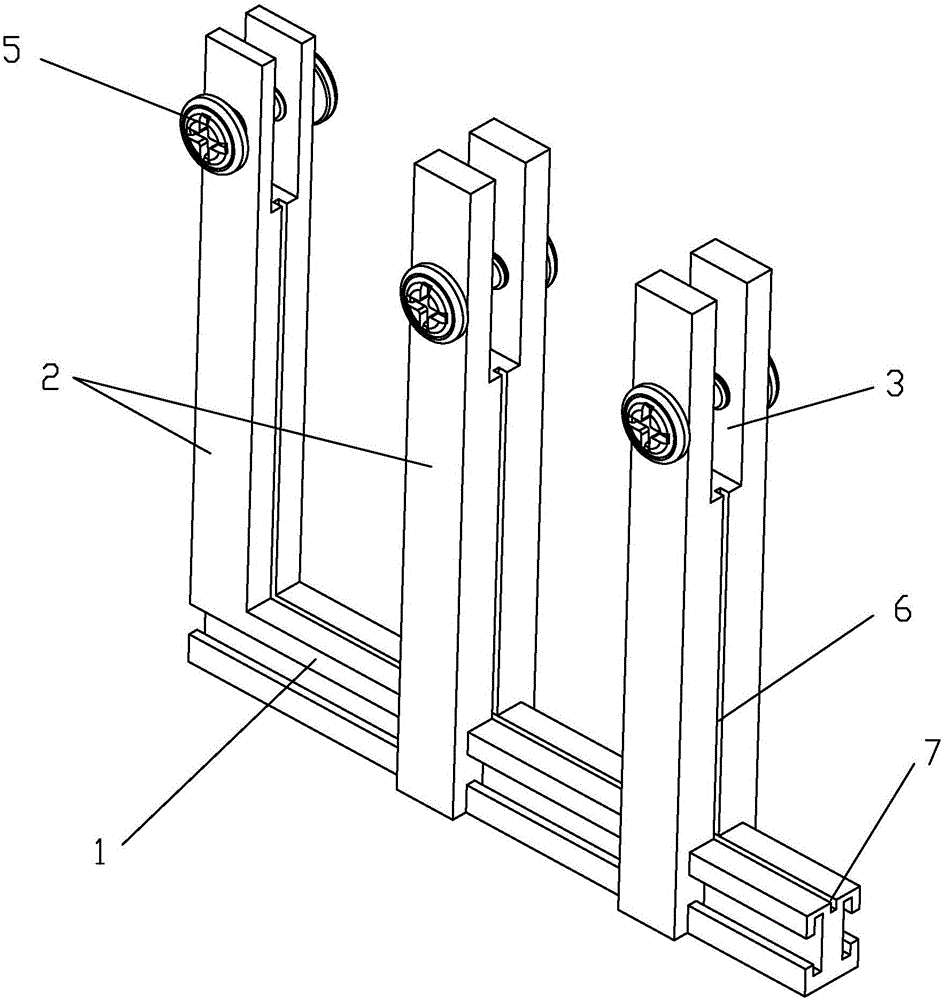

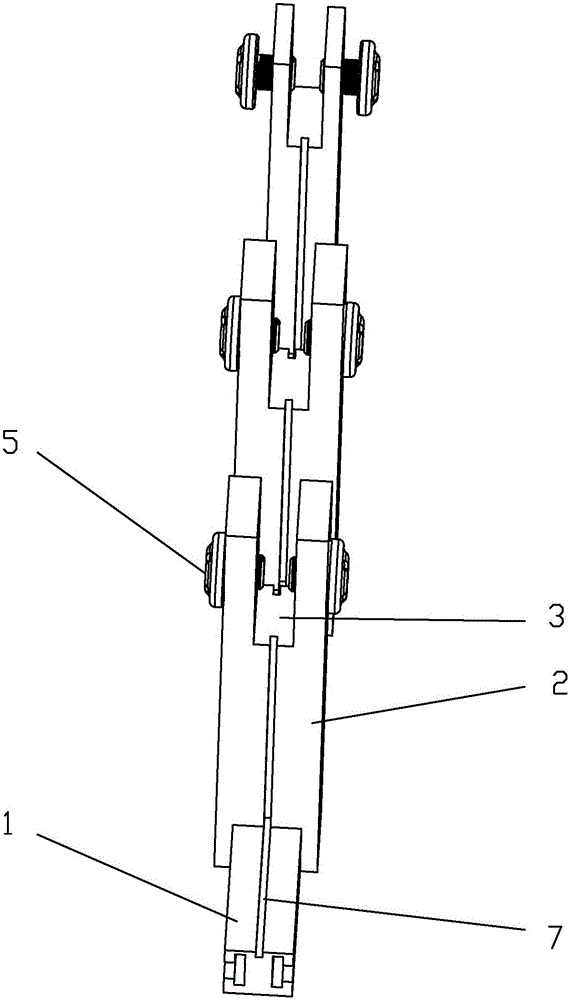

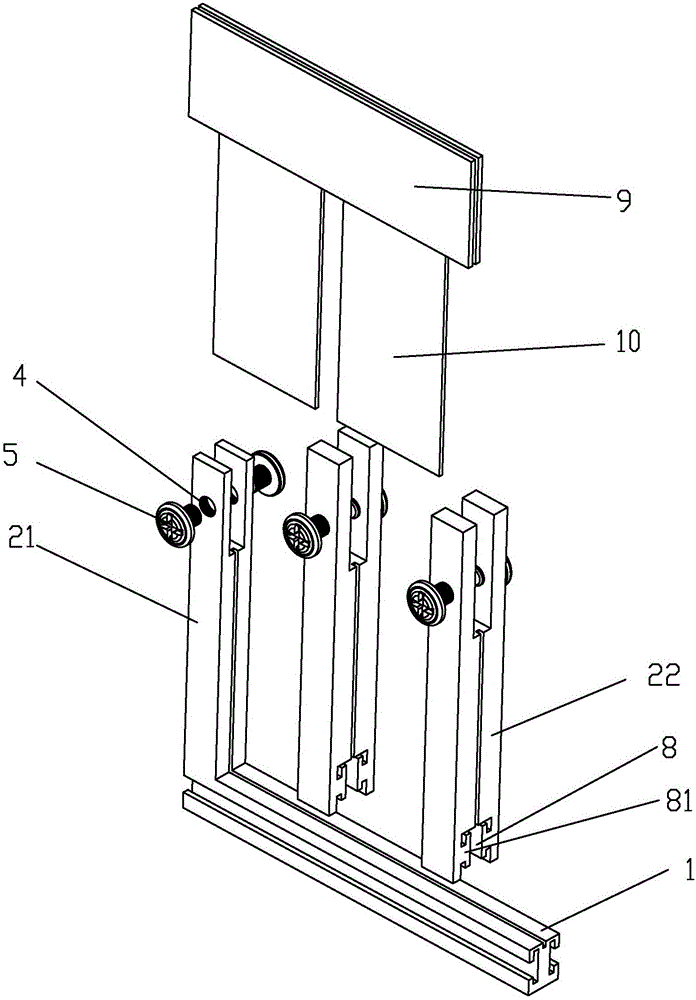

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] A ceramic circuit board fixture for electroplating, comprising a bottom plate 1, a plurality of splints 2 are vertically arranged on the bottom plate 1, and edge strip slots 3 for placing conductive edge strips 9 are arranged on the upper ends of the splints 2. The side of the clamping plate 2 is provided with a vertical clamping plate shallow groove 6 communicating with the side bar slot 3 for inserting the side of the ceramic circuit board 10, and the splint 2 on both sides of the side bar slot 3 is provided with threaded holes 4, so The threaded hole 4 is provided with an adjustable screw 5 that presses against the side of the conductive strip 9 to clamp the ceramic circuit board 10 .

[0024] During use, first clean the surface of the ceramic circuit board 10, then put the ceramic circuit board 10 into the shallow groove 6 of the vertical clamping plate of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com