Gypsum needle type stirrer

A mixer and pin-type technology, applied in the field of pin-type mixers, can solve problems such as uneven mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

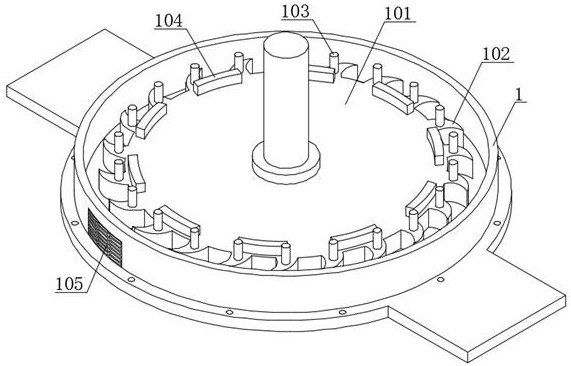

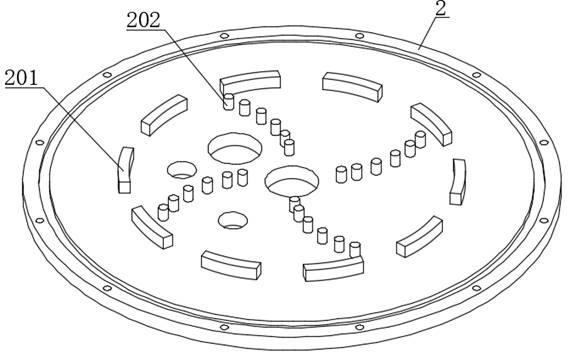

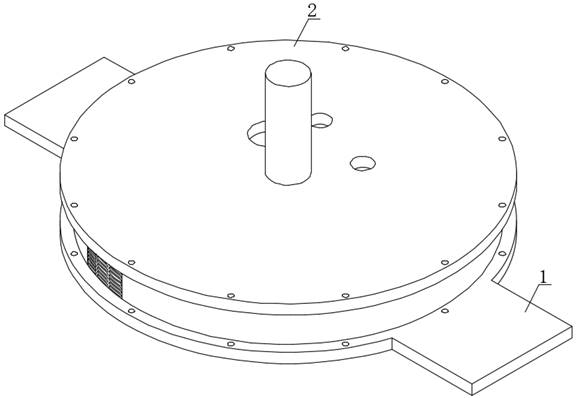

[0030] Example 1 please refer to figure 1 The embodiment shown in -4 is a gypsum pin mixer, which includes a base 1 and an upper cover 2 fastened to the base 1. Both the upper cover 2 and the base 1 are fixed, and the base 1 is rotatably connected with a turntable. 101, the middle part of the turntable 101 is a rotating shaft, which runs through the upper cover 2 and is connected to the external rotating power device, which drives the turntable 101 to rotate at a high speed, and the outer edge of the turntable 101 is provided with cutting arc teeth 102 in a circular array, and the cutting The material arc teeth 102 are fixedly connected with an external stirring needle 103, the rotating disk 101 is fixedly connected with an outer retaining ring 104 in a spaced shape, and the upper cover 2 is fixedly connected with an inner retaining ring 201 in a spaced shape, and the inner retaining ring 201 and The outer retaining ring 104 is cut off in the vertical direction, and the partit...

Embodiment 2

[0033] Example 2 please refer to Figure 5 In the illustrated embodiment, the same parts will not be repeated. The inner retaining ring 201 and the outer retaining ring 104 are separated in the horizontal direction, and the horizontal partition gap is larger than the gap between the inner retaining ring 201 and the outer retaining ring 104, which can make the material quickly Outflow, the diameter of the inner ring of the outer retaining ring 104 is greater than the diameter of the outer ring of the inner retaining ring 201, the gap between the two is 3-5 mm, preferably 3 mm, this gap is to further limit the material output granularity.

[0034] The material can flow out through the slit of the inner retaining ring 201, and is cut by the rotating outer retaining ring 104 when between the inner retaining ring 201 and the outer retaining ring 104, and the cutting work is completed.

Embodiment 3

[0036] Example 2 please refer to Figure 6 In the illustrated embodiment, the same parts will not be repeated. The inner retaining ring 201 and the outer retaining ring 104 are separated in the inclined direction. Outflow quickly, the diameter of the inner ring of the outer retaining ring 104 is greater than the diameter of the outer ring of the inner retaining ring 201, the gap between the two is 3-5 mm, preferably 3 mm, this gap is for further restriction The output granularity of the material.

[0037] The material can flow out through the slit of the inner retaining ring 201, and is cut by the rotating outer retaining ring 104 when between the inner retaining ring 201 and the outer retaining ring 104, and the cutting work is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com