Rare earth neodymium containing trivalent chromium blue and white passivation liquid and preparation method thereof

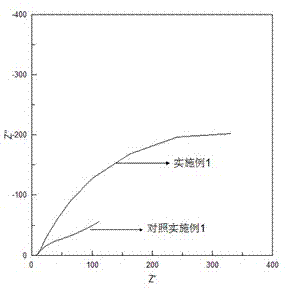

A technology of trivalent chromium and passivation solution, applied in the direction of metal material coating process, etc., can solve the problems of microporous defects, rough surface of passivation film, etc., to improve air tightness and corrosion resistance, and uniform film layer. dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

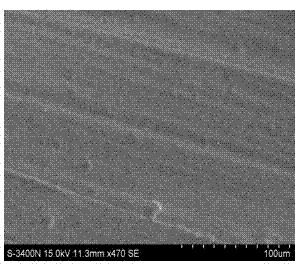

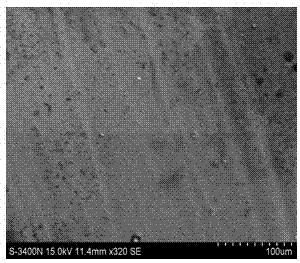

Embodiment 1

[0034] A trivalent chromium blue-white passivation solution containing rare earth neodymium, calculated per liter, its composition and content are as follows:

[0035] 18g chromium sulfate

[0036] 2.2g sodium nitrate

[0037] 7g cobalt sulfate heptahydrate

[0038] 3.4g sodium hypophosphite

[0039] 0.7g citric acid

[0040] 0.2g ammonium bifluoride

[0041] 0.28g neodymium nitrate

[0042] The balance is deionized water.

[0043] A kind of preparation method of above-mentioned trivalent chromium blue-white passivation solution containing rare earth neodymium, the steps are as follows:

[0044] First, under the condition of continuous stirring, dissolve 18g of chromium sulfate in 500ml of deionized water, then add 0.7g of citric acid, 3.4g of sodium hypophosphite, and 2.2g of sodium nitrate to dissolve it, and then add 7g of cobalt sulfate heptahydrate And make it fully dissolved, finally add 0.2g ammonium bifluoride and 0.28g neodymium nitrate succe...

Embodiment 2

[0075] A trivalent chromium blue-white passivation solution containing rare earth neodymium, calculated per liter, its composition and content are as follows:

[0076] 15g chromium sulfate

[0077] 2g sodium nitrate

[0078] 6g cobalt sulfate heptahydrate

[0079] 2.5g sodium hypophosphite

[0080] 0.5g citric acid

[0081] 0.15g ammonium bifluoride

[0082] 0.14g neodymium nitrate

[0083] The balance is deionized water.

[0084] A kind of preparation method of above-mentioned trivalent chromium blue-white passivation solution containing rare earth neodymium, the steps are as follows:

[0085] First, under the condition of continuous stirring, dissolve 15g of chromium sulfate in 500ml of deionized water, then add 0.5g of citric acid, 2.5g of sodium hypophosphite, and 2g of sodium nitrate to dissolve it, then add 6g of cobalt sulfate heptahydrate and Make it fully dissolved, and finally add 0.15g of ammonium bifluoride and 0.14g of neodymium nitrate s...

Embodiment 3

[0094] A trivalent chromium blue-white passivation solution containing rare earth neodymium, calculated per liter, its composition and content are as follows:

[0095] 20g chromium sulfate

[0096] 3g sodium nitrate

[0097] 8g cobalt sulfate heptahydrate

[0098] 4g sodium hypophosphite

[0099] 0.8g citric acid

[0100] 0.25g ammonium bifluoride

[0101] 0.42g neodymium nitrate

[0102] The balance is deionized water.

[0103] A kind of preparation method of above-mentioned trivalent chromium blue-white passivation solution containing rare earth neodymium, the steps are as follows:

[0104] First, under the condition of continuous stirring, dissolve 20g of chromium sulfate in 500ml of deionized water, then add 0.8g of citric acid, 4g of sodium hypophosphite, and 3g of sodium nitrate to dissolve them, then add 8g of cobalt sulfate heptahydrate and make It is fully dissolved, and finally add 0.25g of ammonium bifluoride and 0.42g of neodymium nitrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com